SCARA Robot vs. 6-Axis Robot: Which is Best For Your Application?

While industrial robots can lend speed, accuracy and greater levels of efficiency to an operation, they are not a one-size-fits-all solution. As a matter of fact, selecting the right robot for an application is critical to the success of any automation project. In this blog, we’ll compare and contrast two of the most commonly applied industrial robots – SCARA robots and 6-axis robots – to help you decide which may be the most suitable robot type for your automation needs.

We’ll begin by defining each type and listing its advantages, disadvantages and common applications and then provide some considerations for robot selection.

SCARA Robot vs. 6-Axis Robot

What is a SCARA Robot?

Selective Compliance Articulated Robot Arms, or SCARA robots, feature a robot arm with several joints to provide flexibility and are often fitted with end-of-arm tooling specially designed for the application.

Designed to mimic the human arm, SCARA robots offer a unique range of motion. Mounted on a pedestal, they offer a circular work envelope along three axes: the X, Y and Z planes and a fourth axis at the end of the Z plane (think of the wrist at the end of a human arm) that rotates the end-of-arm tooling. This design allows a SCARA robot to move horizontally in any direction within its workspace. SCARA robots can also move vertically, but with some restriction as the vertical axis remains fixed.

SCARA robot advantages include:

High speeds

Because they have fewer axes and are compact, SCARA robots are one of the fastest industrial robots.

High precision

The rigid Z axis prevents unnecessary up-and-down movements enabling high levels of precision.

SCARA robot disadvantages include:

Limited reach

By design, SCARA robots have a limited reach, typically under 1,000 mm.

Limited range of motion

With four axes, SCARA robots have a more limited range of motion when compared to a 6-axis robot.

Limited payload

SCARA robots offer a typical load capacity of 20 kg or less.

With their high levels of speed and accuracy, SCARA robots excel in many applications, including:

- Pick and place

- Palletizing and depalletizing

- Machine loading and unloading

- Small part assembly

- Dispensing

- Small-scale 3D printing

What is a 6-Axis Robot?

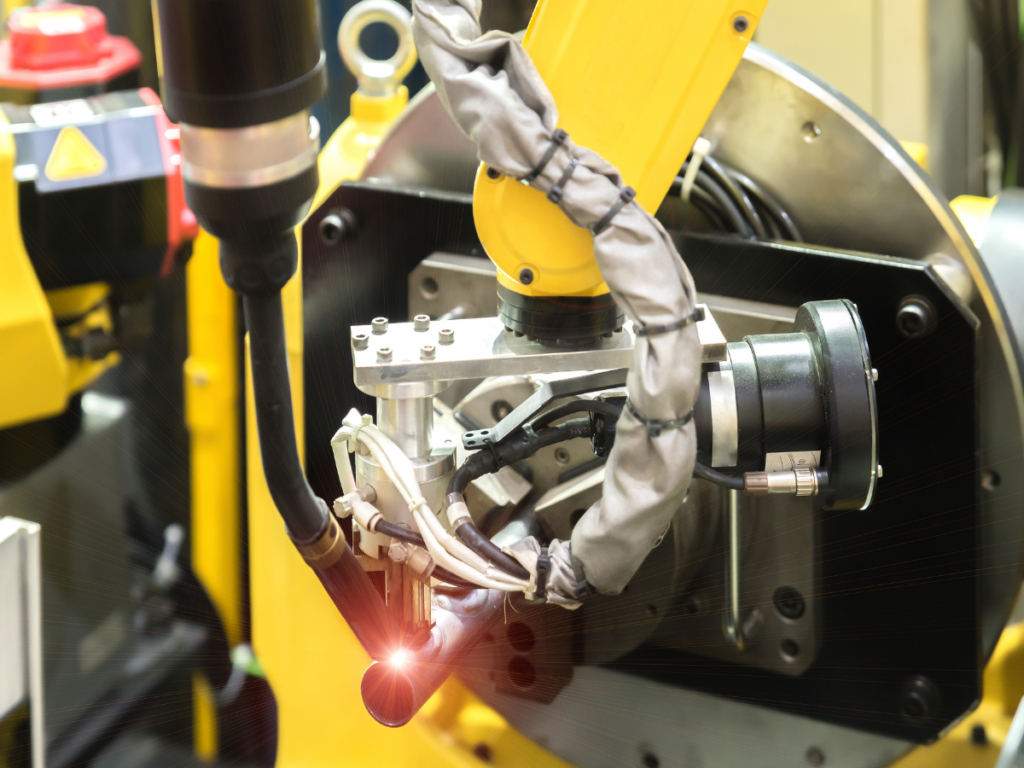

Offering six degrees of freedom, this type of articulated robot is the most common robot used in manufacturing applications. Because six-axis robots can move in the X, Y and Z planes and can perform roll, pitch and yaw movements, six-axis robot arms easily mimic the movements of a human arm and provide exceptional directional movement and control, flexibility, strength and reach.

6-axis robot advantages include:

Flexibility

With six degrees of freedom, six-axis robot arms can mimic the movements of a human arm and can reach in and around objects in the work envelope. They offer greater flexibility and a better range of motion than SCARA robots.

High payload capacity

Six-axis robots may provide up to 600 kg payload capacity.

Wide variety of reaches

Six-axis robot arms come in a variety of reaches as they are available in short-arm and extended reach models, with typical reach ranges from 1,000 to 2,000 mm.

6-axis robot disadvantages include:

Slower speeds

Due to the nature of the design, 6-axis robots tend to be slower than SCARA robots.

Less precise

While they are more accurate and repeatable than human arms, 6-axis robot arms are slightly less precise than SCARA robots.

Less compact

Six-axis robots are generally larger in size and require a larger work zone than SCARA robots.

Higher cost

Because 6-axis robots offer more axes and are larger and more complex, they are usually more expensive than SCARA robots.

With their greater reach and payload capacities, as well as flexibility and wide range of motion, 6-axis robots are well suited for the following applications:

- Welding

- Painting

- Palletizing

- Pick and place

- Machine tending

- Inspection

- Complex assembly

SCARA Robot vs. 6-Axis Robot: Considerations for Selection

The key to successful implementation of any automation project is careful selection of the industrial robot. Taking the time to choose the most suitable robot ensures that it will be able to carry the required load, maneuver within the workspace, manipulate objects and offer the necessary range of motion to function effectively in the operation.

While both six-axis and SCARA robots are great options for pick and place, assembly, palletizing, machine tending and other applications, each robot type has advantages and disadvantages that will make them more or less suitable for certain applications.

Below are 6 considerations for choosing between SCARA and six-axis robots:

| Application details | Knowing what you want the robot to do and where it will be placed are critical considerations when choosing between a SCARA and six-axis robot. In order to be sure you’re picking the right robot, it’s important to consider each step of the process, as well as factors such as the distance the robot will need to reach and the weight of any objects the robot will have to manipulate. |

| Required reach | It is essential to know the maximum distance the robot will need to reach to effectively accomplish the task. Consider the maximum vertical reach (measured from the lowest point that the robot can reach to the maximum height), as well as the maximum horizontal reach (the distance from the center of the base to the furthest point it can reach horizontally). Other considerations include the ability to maneuver around objects and obstacles in the workspace. |

| Payload capacity | This is the maximum load that the robot can handle. The payload includes the part the robot will handle, as well as any end effectors or grippers that will be added to the robot. Every robot model offers a different load capacity, with 6-axis robots having a greater payload capability than SCARA robots. Ensure that the type and model you select can effectively manage the weight and size of the objects the robot will handle. |

| Running speed | The robot’s speed over the required distance is a major factor in how quickly the robot can accomplish the task. SCARA robots tend to be faster than 6-axis robots, but only along the horizontal axis. Six-axis robots are more dexterous. It’s important to determine which is more important in the application – high speeds or dexterity – and make the tradeoff. In either case, it’s important to evaluate the speed requirements of the application and make sure the selected robot can keep pace with production and will provide enough speed to increase efficiency. |

| Repeatability | Repeatability is the ability of the robot to reach the same position each time it completes a routine, so in applications where high accuracy is required, the better the repeatability needs to be. |

| Space and Footprint | The available size of the area in which the robot will be expected to perform is important during the selection process. Confined areas and obstacles will impact this, as well. If space is very limited, the smaller SCARA robot may be required as they are more compact than 6-axis robots. |

Choosing between industrial robots can be a complex process, but it is essential to ensure that the robot operates effectively and efficiently in the automation project. The experts at JHFOSTER, a Tavoron company, can help you decide whether a 6-axis or SCARA robot is right for your application.