Gear Motors

JHFOSTER, the industry’s leading gear motor distributor, carries a wide variety of gear motor sizes, power ratings, and ratios – you are sure to find one that fits your specific application.

Choose from our extensive selection of high-quality gear motors from top manufacturers, and get the power and performance you need without spending more than you have to.

What Is a Gear Motor?

A gear motor is a type of electric motor used to decrease the motor’s speed and increase the torque output. They offer greater torque and reduced speed when compared with direct-conversion designs. This is crucial in various applications, such as adjusting the speed of stirring mechanisms and controlling conveyor belts.

The gear housing design, gearing type, gear lubrication, and the manner in which it is integrated all impact gear motor performance and life.

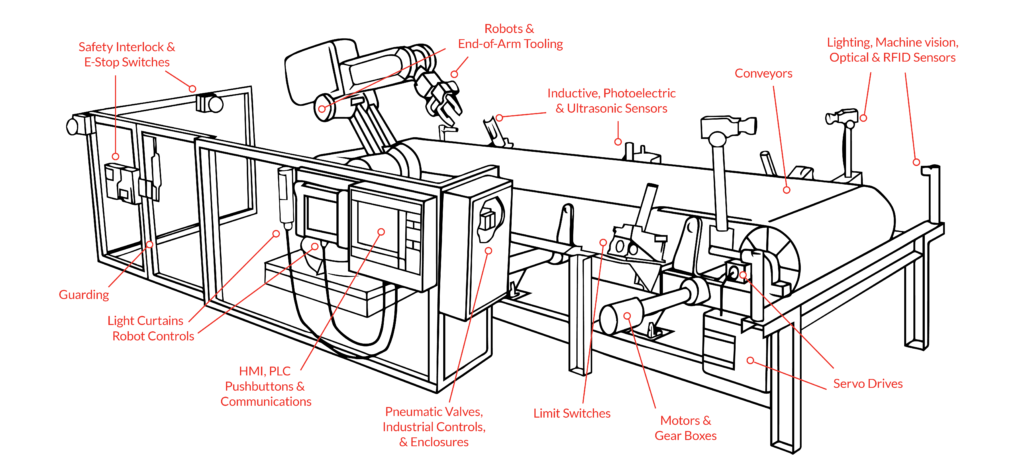

Gear motors are commonly used in conveyor systems, material handling equipment, and other industrial machinery. They can also be used in electric vehicles, such as golf carts and forklifts.

Different Types of Gear Motors

There are several types of gear motors available on the market today. The most common types include:

- Inline Gear Motors: Inline geared motors are made from a single body piece, minimizing wear and deformation. These are great for rugged applications in construction, electricity, and shipping because they offer better resistance to wear and strain.

- Right-Angled Gear Motors: These are electric motors with a gear reducer attached to them. Their compact size makes them a superior choice in food service, agriculture, and medical automation.

- Parallel Shaft Gear Motors: High-quality components are used in parallel shaft geared motors to decrease the speed of a machine’s operation. They are frequently used in mixing devices that work with big batches of liquids.

- Planetary Gear Motors: Planetary gear motors are used in high-precision motion control systems that require a lot of torque, torsional stiffness, and backlash. They are recommended for motors with superior efficiency at higher speeds.

Your Trusted Gear Motor Supplier in Minnesota

Achieve greater operational efficiencies and dramatically reduce maintenance costs with gear motors that provide superior quality and performance.

Our experienced technicians will guide you through your brand new gear motor’s specification, design, and implementation phases to ensure that you get the most out of your investment.

Reach out to us today to get your free quote. For more information on our products and suppliers, don’t hesitate to call us at 855-688-0065.

Literature Library

Looking for additional information? Check out JHFOSTER’s Automation Library.

TECHNOLOGY

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

Frequently Asked Questions

When selecting a gear motor, consider the desired speed and torque output, the power source (AC or DC), mounting options, and environmental conditions.

Other considerations such as gear ratios, encoder inputs, and brake options may also be important depending on your specific application.

The amount of heat a motor can dissipate is dependent on the type of cooling (air, water, or oil) and the size of the motor. Water-cooled motors can typically handle more heat than those that are air-cooled.

The size of the motor also affects how much heat it can dissipate. Larger motors generally have more surface area and can therefore dissipate more heat.

The top speed of a gear motor depends on the size, gear ratio, and the type of gearing (spur, helical, bevel, etc.).

Request More Information