Category: Industrial Robotics

Who Makes the Best Industrial Robot?

That depends on your application and needs. Industrial robots are suitable for many tasks. From injection molding to packaging, the repetitive tasks within your business could be easily automated. The possibilities are nearly endless. However, if you’ve been researching different industrial robot manufacturers, you may be struggling to identify which one is right for you. […]

What Are the Signs Your Collaborative Robot Needs Repair?

Your collaborative robot, also known as a cobot, has been working hard to increase efficiency and reliability within production. This new technology has quickly paid for itself and has become indispensable for human coworkers working alongside the robot. Or perhaps you have used robotic technology for quite some time, and it has become a staple […]

Ways Robotic Technology Enhances Worker Safety

Robotic technology is becoming a mainstay of many industrial environments. From packaging applications to lab analysis and testing, robots are being used for a variety of tasks previously performed by humans. As robotic technology rolls out, many companies are wondering about how safe robots are for their human coworkers. Are robots truly safe to be […]

Simplify Industrial Applications with Collaborative Robots & EtherNet/IP Communication Protocol

Simplifying industrial applications can seem like an arduous task for yourself and your team. Maybe you have introduced collaborative robots to simplify repetitive tasks within your facility, but you are finding that your applications require multiple cobots running in tandem. Running many systems and technology at once to create your end-product can soon become complicated. […]

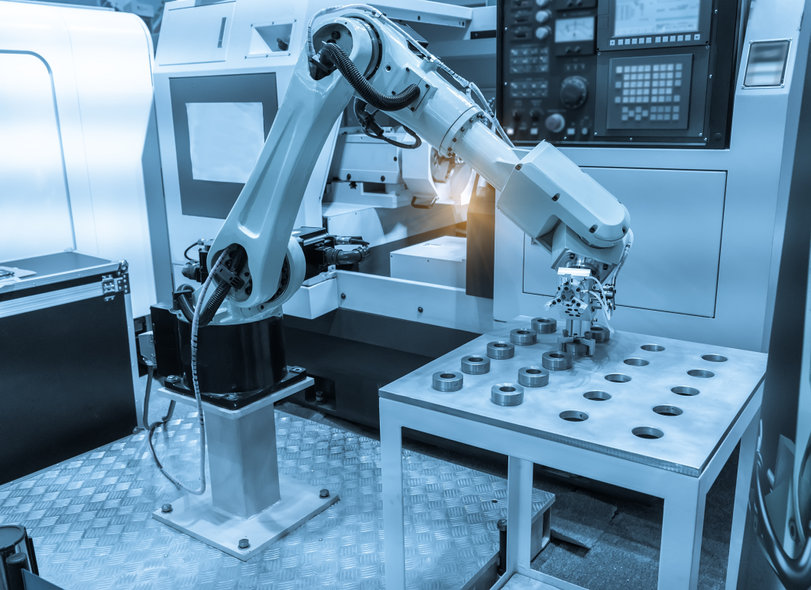

What Is Robotic Automation?

Robotic automation is simply a variation of automation that uses robotic technology to simplify a task or application. Robots perform tasks that range from painting a car in a factory to packaging food product. There is a large array of robot types, as well as, robotic accessories. Let’s dive into the different types of robots […]

What Are The Differences Between Cobots & Other Robots?

On a recent podcast, Dustin Hrubetz, JHFOSTER’s Manager of Robotic Distribution and Industrial Application, talked about a few differences between cobots and other robots. He also discussed some of the applications cobots (collaborative robots) are being used for in current markets. In this blog post, we are going to talk further about these topics. Keep reading […]

4 Industries that Could Benefit the Most from Robotics

According to the International Federation of Robotics, the United States is the leading user of industrial robots in the Americas, with approximately 293,200 robots currently in operation over a wide range of industries. However, robots have not just reached American companies. The adoption of human-robot collaboration is on the rise with nearly 2.7 million robots […]

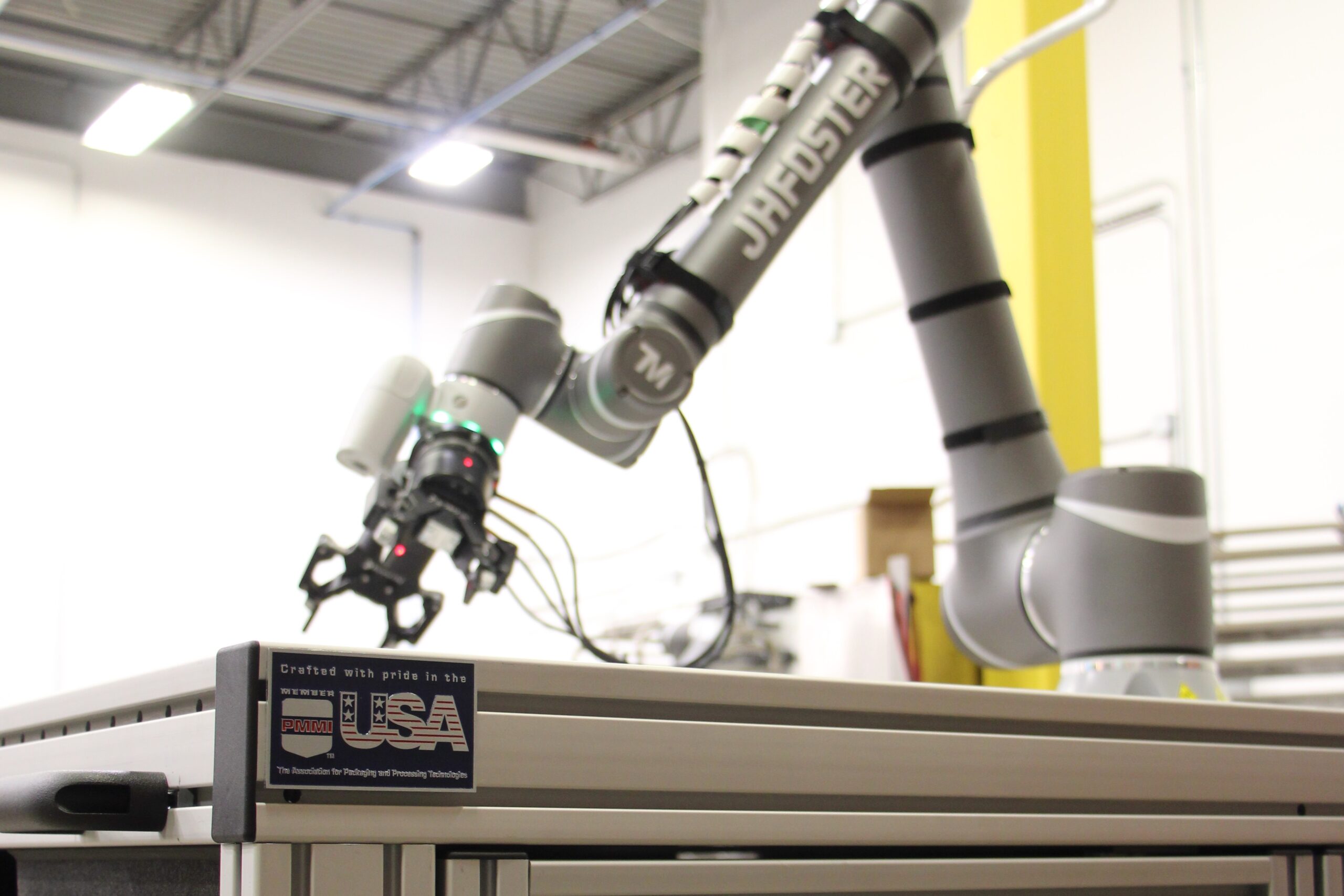

Techman Robot: Getting College Students Ready for the Workforce

Recently, JHFOSTER helped a Midwestern university to educate STEM students with the help of Techman Robots. Techman Robots help students learn alongside technology that they may see or use in their future careers. As robots begin to help more and more companies increase efficiency and reliability, more staff are having to become accustomed to working […]

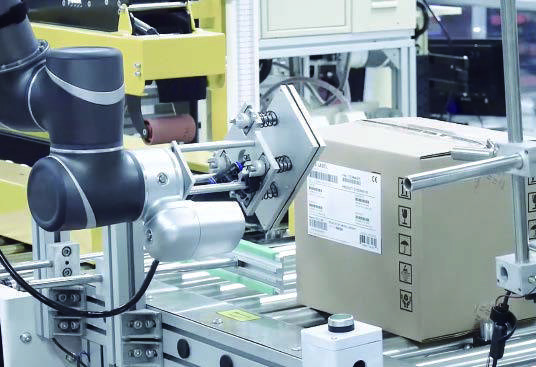

How To Use Robots For Vision Guided Box Packing

A robot with a vision system can do just about anything. In fact, robots are used for pick and place, injection molding, CNC, packaging and palletizing, quality inspection, assembly, polishing, machine tending, screw driving, lab analysis and testing, gluing, dispensing, and welding. The reason robots are used so prevalently in these applications is due to […]

Cobots and Coronavirus: Can They Help Preserve Our Health?

Collaborative robots have increased in use since the beginning of COVID-19. From helping maintain production in a healthy way to producing the PPE we need more than ever, Cobots are a great partner for our world in the “new-normal”. Therefore, Cobots and coronavirus have become hot topics in the automation world lately. Cobots can help […]