The Role Actuators Play in Keeping Robots in Motion

Robotic actuators are an important component in any industrial robotic system as they convert energy into smooth and accurate robotic performance, essentially serving as the muscle behind a robot’s movements. The blog will explore the various types of actuators in robotics, the importance of robotic actuators in industrial applications, the benefits of using robot actuators in these automated systems and selection criteria for a robotic actuator.

What is a Robot Actuator?

Industrial robots must move in smooth and precise ways in order to perform simple or complex tasks such as lifting pallets, picking up and putting down objects, assembling components and other common robotic activities. To effectively perform any of these activities, robots must be equipped with actuators, which enable simple movements such as rotating joints or more complex motions such as grasping a part.

Robotic actuators are mechanical devices that enable motion, object handling and other common robot activities based on signals sent from the system controller. Several types of robot actuators are available to suit a variety of tasks and choosing the right one greatly impacts the performance and efficiency of the robot.

Below are commonly used actuators in robotics, as well as other applications, and their attributes:

This type of robotic actuator converts electrical energy into mechanical motion and offers high speed, precise motion, excellent response times and accurate control. Electric actuators often include feedback devices for tighter control. They are also cleanroom and sanitary application friendly.

Hydraulic actuators use hydraulic fluid to create and control movement. As robotic actuators, they provide significant force, strength and power for simple movements that don’t require sudden stops or starts and can be used when the operating environment includes shock and vibration.

Pneumatic actuators convert compressed air into mechanical energy to create force. This type of robot actuator is capable of high speeds and offers accurate and repeatable motion profiles. Because pneumatic devices are air operated, they can safely be used in locations where fire or explosions are a risk.

7 Benefits of Using Actuators in Robotics

Robotic actuators are crucial components because they provide the precision and accuracy that are necessary for successful industrial robot systems. But the advantages of using actuators for keeping robots in motion don’t stop there.

Here are 7 benefits associated with using actuators in robotics:

- Accuracy and precision: Robotic actuators move with high levels of precision and accuracy, which are essential in grasping, grabbing, cutting and similar robotic applications.

- Efficiency: Robot actuators operate reliably at high speeds in industrial applications, which helps improve productivity, uptime and efficiency of the operation.

- Flexibility: Because there are different types of robotic actuators, there is likely a solution that will enhance even the most unique application.

- Speed: Today’s robot actuators are designed to perform tasks at high speeds with high levels of precision and accuracy, making them more efficient and effective than the human hand.

- Repeatability: Tightly controlled robotic actuators can perform repetitive tasks without errors, providing repeatability and ensuring consistent performance and higher levels of product quality.

- Reliability: When the most suitable robot actuator is selected for an application, it will provide reliable, low-maintenance service, helping to avoid downtime and improve productivity.

- Cost effectiveness: Because robotic actuators perform reliably and offer great accuracy, precision and repeatability, they help reduce waste, increase efficiency and minimize maintenance, which improves the cost effectiveness of the operation.

5 Applications where Robot Actuators Shine

Robotic actuators are used extensively in modern robotic and automated systems. Below is just a small sampling of the ways these essential components keep today’s robots in motion and provide smooth, precise, accurate and repeatable motion.

| Welding operations | Robot actuators are used in welding robots to provide the precise and efficient movements required to enable a high-quality weld. |

| Painting processes | Actuators are used in robot arms to provide the smooth and precise motion needed to apply an even coat of paint. |

| Quality control | In robots that perform durability testing for quality control, robotic actuators reliably perform the same repetitive motions thousands of times to test the durability of manufactured consumer products. |

| Part feeding | Robotic actuators allow industrial robots to grasp objects with accuracy on assembly lines or for material handling purposes. |

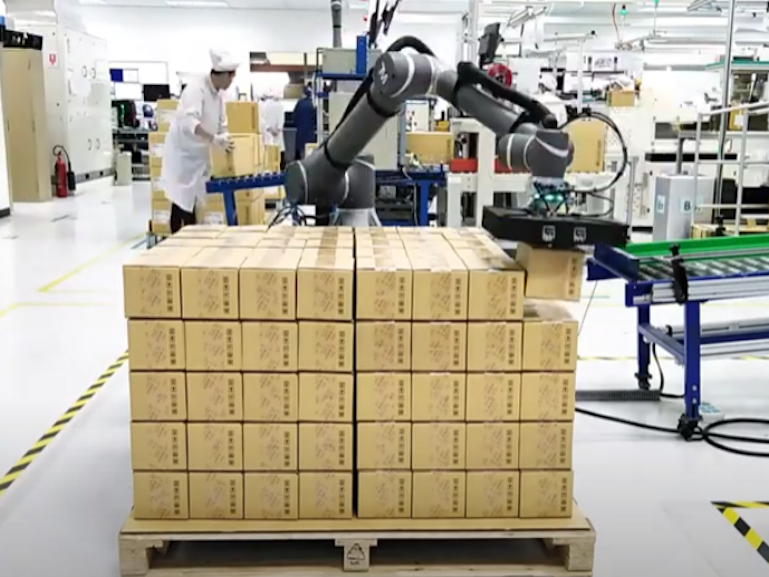

| Loading and unloading | Reliable and robust robotic actuators provide the strength and accuracy to repeatedly load and unload heavy parts, pallets or other objects in industrial settings. |

Selecting a Robotic Actuator for an Application

While robot actuators are proven to reliably enable smooth, precise motion in robotic systems, performance will be enhanced when the selected actuator matches the specifications of the task where it will be applied.

To ensure that the chosen robot actuator provides the highest levels of efficiency and performance, be sure to understand the metrics of the application including:

- Speed and response time: If the goal is to increase efficiency of an operation, speed and response time are important criteria. Speed is how quickly the actuator can move, while response time refers to the time it takes the robot actuator to respond to a command.

- Force and torque: Force ratings specify the amount of linear force that can be provided by an actuator, while torque is the rotational force. These ratings determine how much load the robotics actuator can reliably manage.

- Precision and accuracy: In applications such as welding, assembly and others that demand exact positioning or movement, accuracy and precision are essential specifications. Accuracy is the ability of an actuator in robotics to achieve the desired position and precision is the ability to exactly repeat the same motion.

By considering the application and ensuring that the specifications of the robotics actuator are a good fit, the performance of the operation will be enhanced. For assistance selecting a robot actuator that will best keep your robot in motion, please contact the experts at JHFOSTER, a Tavoron company, today.