Category: Pneumatic Actuators

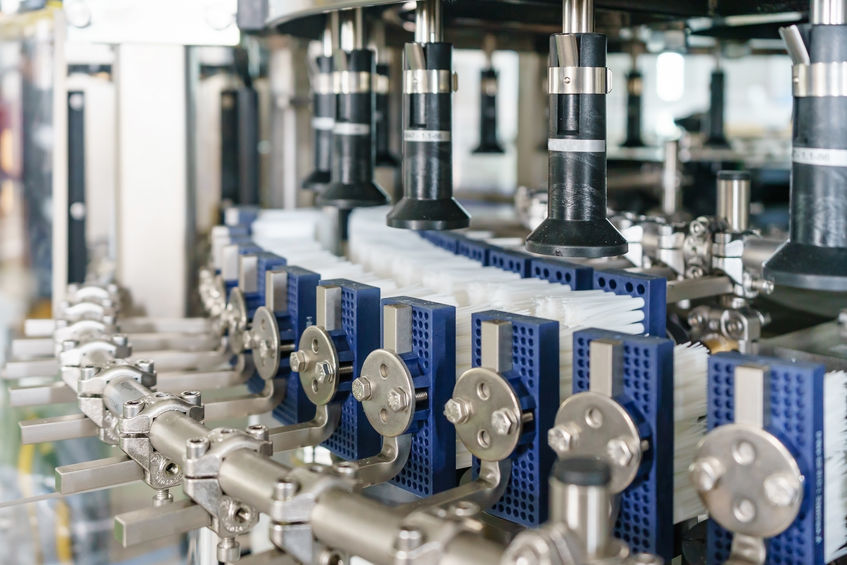

Actuators: Creating Movement in Manufacturing

The factory floor in most manufacturing facilities is a very active place. From the front door to the back, there is likely a whirlwind of motion and movement as automated machinery transports, picks, cuts, stamps, assembles, processes, produces and packages products. While it may seem like all of this productivity is controlled with the touch […]

Choosing the Right Actuator Type for Your Application

Sometimes the choice between the three main actuator types – electric, pneumatic and hydraulic – is a no brainer. For example, if you need heavy-duty motion, a hydraulic actuator would be the obvious choice, a potentially explosive environment necessitates the use of a pneumatic actuator and a sterile operation would demand an electric actuator. But […]

Actuators: The Muscle Behind Industrial Motion

Similar to the way in which muscles in the human body enable motion of the arms, legs and other body parts, actuators facilitate mechanical movement. As a matter of fact, nearly every piece of industrial equipment relies on actuators to generate the motion needed to properly operate; however, the actuator used differs from application to […]

What are the 4 Main Types of Linear Actuators?

Linear actuators provide push or pull straight-line motion and are often used for lifting, dropping, sliding or tilting of machines, objects or materials. Because they provide precise and efficient linear movement, they are essential in many automation, robotics and motion control applications in a variety of industries, including: The Benefits of Linear Actuators One of […]

Electric vs. Pneumatic Actuators: Which One is Right for You?

The choice between pneumatic and electric actuators is not always an easy one. However, the two technologies are so different that one can rarely be a replacement for the other. Many variations exist to meet the demands of the compressed air market. There are a few key points that can help you to decide between electric and […]

The Differences Between Rotary and Linear Pneumatic Actuators

Linear Pneumatic Actuators can move something in a straight line using a piston with compressed air applied to achieve linear motion. The output motion of Linear Pneumatic Actuators is in line with the piston rod and/or cylinder. Rotary Pneumatic Actuators can move something in a circular motion. Perpendicular to the shaft. Many contain pneumatic piston-operated rack & pinion […]

Regular Maintenance Ensures Functional and Efficient Pneumatic Systems

While pneumatic systems are often selected because they have a reputation for providing high reliability in tough industrial applications, that doesn’t mean that they don’t require a little TLC now and then. As a matter of fact, creating and adhering to a schedule of regular inspection and maintenance activities will ensure that your pneumatic systems […]

The Truth about Accuracy in Linear Actuators

When specifying a linear actuator, the first question most people ask is: “How accurate is it?” There is no simple answer and it is possible that it’s not even the right question to ask as accuracy may not be the most important parameter for a given application. While accuracy is often viewed as the most […]

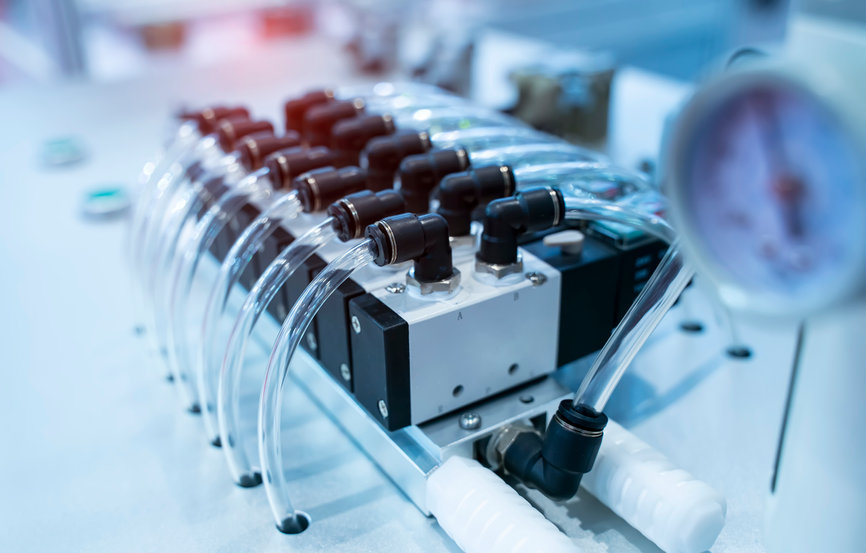

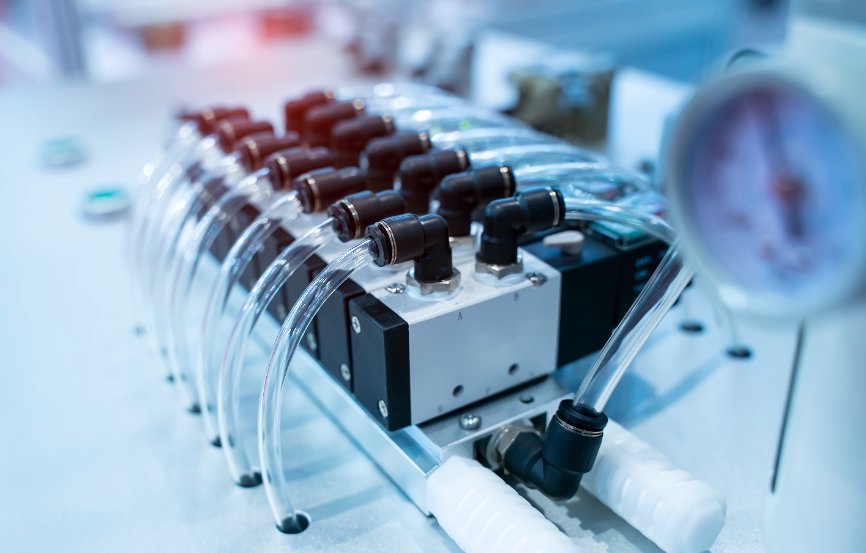

Why Replace a Valve System with a Manifold?

As the number of valves in a pneumatic system grows, flow paths can begin to look like a plate of spaghetti. Aesthetics aside, these sprawling flow paths often increase the overall size of the valve system, lengthen response times and lead to leaks. For these reasons, it can be beneficial to replace space-hogging valve systems […]

Pulsed Air-Piloted Valves or Direct-Acting? When OEMs Only Go With What They Know, They May Be Missing Out

By Tom Voth, product marketing manager: pneumatic machine safety and electronic proportional valves, Emerson OEMs are always seeking solutions that reduce machine complexities and minimize operator intervention, and proportional valves are one of many important technologies involved in achieving these design goals. Though several proportional valve designs exist, pulsed air-piloted and direct-acting are the most […]