Category: Pneumatic Actuators

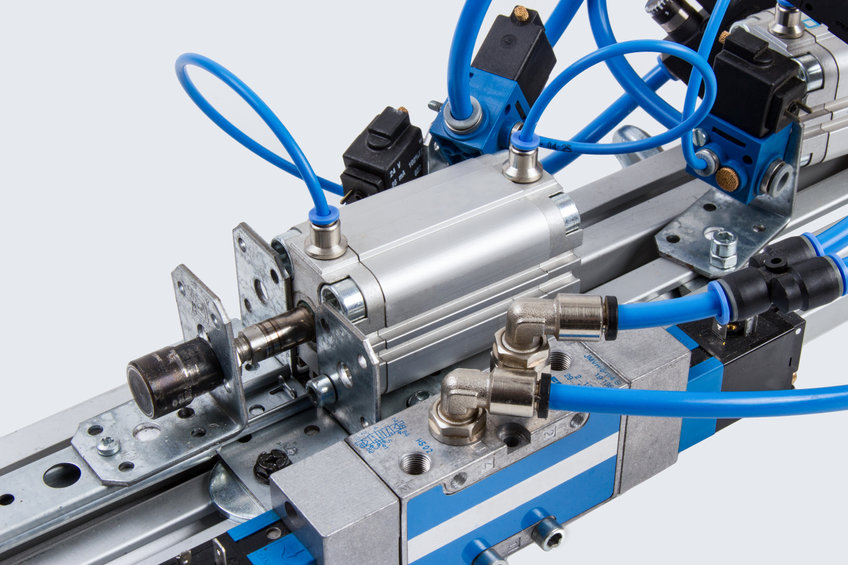

Pneumatic Safety Systems: Redundant Safety Exhaust Valve vs. Zoned Safety for OEM Applications

Written by Tom Voth, Product Marketing Manager, Emerson, and Jeff Welker, product manager, FS Eng (TUV Rheinland, #18333/ 19, Machinery), Emerson OEMs who design equipment with pneumatic safety systems are repeatedly challenged with the dual task of protecting operator safety while also delivering maximum uptime. To accomplish safety goals, OEMs have traditionally integrated redundant safety […]

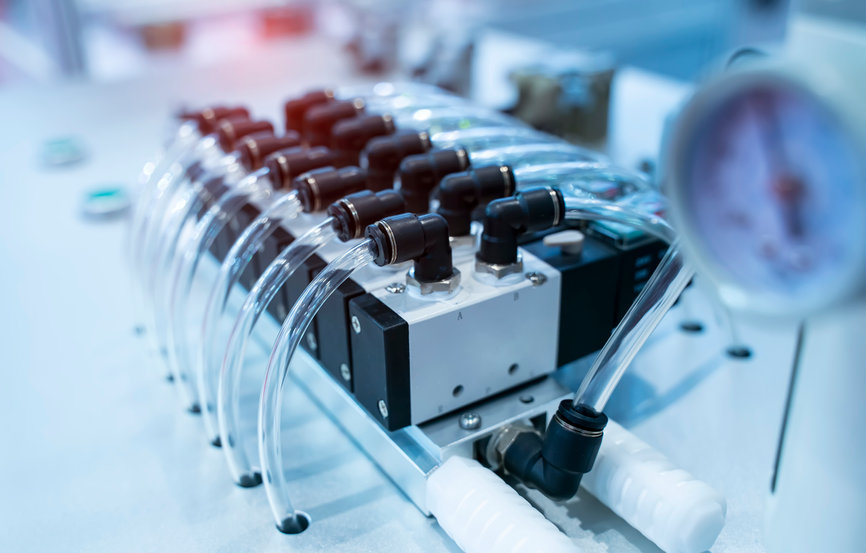

Pneumatic Safety Components and Where to Apply Them

With the introduction of automated systems, building machines has become even more complex. This forced designers to devote more time to implementing newer safety standards. A good example of this is the revision of ISO 13849 in 2006, which meant that all machine builders now had to consider safety-rated components as part of their design […]

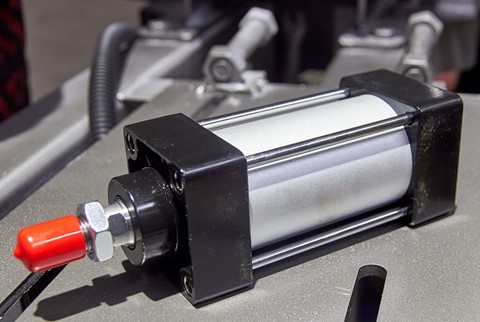

A Brief Guide on Troubleshooting Pneumatic Actuators

Pneumatic actuators are used to convert the energy from pressurized air into rotary and linear motion. With exceptional motion control, it guarantees the precision needed in automation. They are used in many industries, such as automotive, food processing, and manufacturing because of their many benefits. If your pneumatic actuator and its components are not working […]

Ideal Applications For Pneumatic Actuators

Pneumatic actuators are used in many industries utilizing automation systems such as manufacturing, packaging, food and beverage, and automation. These actuators that draw their power from compressed air come in a wide array of sizes and configurations operating at high speeds while offering flexibility. In addition, pneumatic actuators offer both rotational and linear movement allowing […]

The Dangers of Dysfunctional Actuators

Actuators help streamline manufacturing processes while lowering production costs. However, issues and defects in these components can jeopardize the entire production line and result in severe downtime. In manufacturing, downtime can translate to significant financial losses. It is estimated that downtime causes every factory to lose at least 5% of productivity, with some factories losing […]

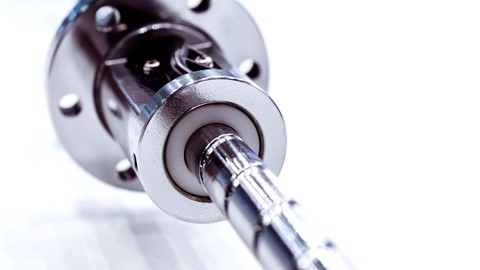

Where Are Linear Actuators Used?

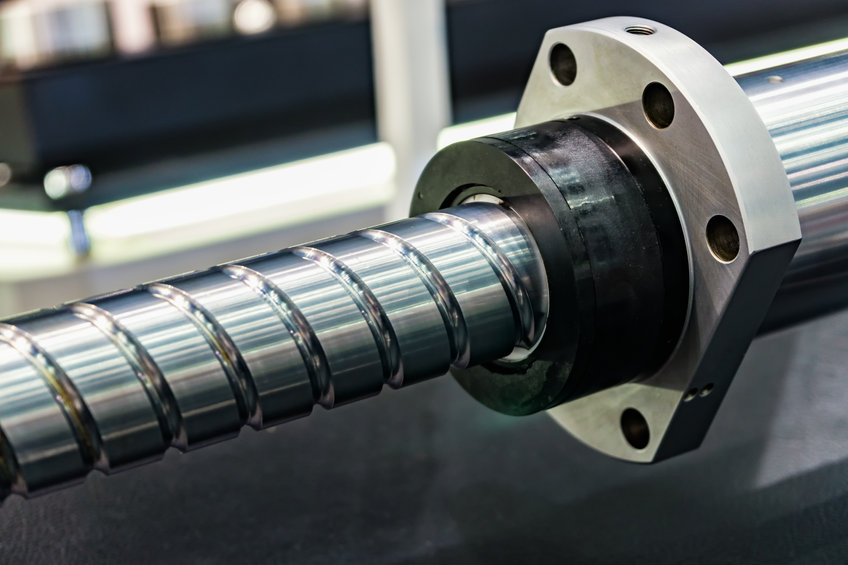

The concept of a linear actuator is a simple one. A linear actuator develops motion in a straight line. This automation technology allows for a great deal of reliability, speed, and efficiency. Linear actuators can come in electric, hydraulic, and pneumatic varieties, although electric adaptations are becoming increasingly common. The reason behind this shift is […]

Save Energy with Pneumatic Actuators

Many leaders in the manufacturing industry know that pneumatic systems consume plentiful energy. Often, those in this particular industry (and many other industries at that) are trying to determine how less energy can be consumed by the various applications that are running throughout a production facility. Naturally, managers turn their attention to applications using pneumatic […]

How To Choose the Right Pneumatic Actuator for Your Application

Pneumatic actuators (also referred to as pneumatic cylinders) are efficient automation technologies that are used for applications requiring linear motion. They are fundamental for many applications within industrial settings but are used widespread in many other industries utilizing automation machinery, notably material handling applications that need to transfer, pick, place, clamp, or index. Not only […]

Electric Actuators vs Pneumatic Actuators

As you know, actuators are “movers” that play a key role when it comes to moving and controlling mechanisms in various industrial applications, including conveyors. Actuators work by drawing energy from some sort of source, and, as you might imagine, there are various types of actuators that typically differ based on where they derive their […]

What are the Types of Actuators

If there’s a piece of machinery operating within your industrial environment, then there’s a good chance that an actuator is working behind the scenes to help it do what it needs to be doing. But contrary to what you may think, there’s more than just one type of actuator – and the actuator that you […]