What are the Types of Actuators

If there’s a piece of machinery operating within your industrial environment, then there’s a good chance that an actuator is working behind the scenes to help it do what it needs to be doing. But contrary to what you may think, there’s more than just one type of actuator – and the actuator that you select should be dictated by the movement you need and the power source you have on hand. Here’s a closer look at the different types of actuators.

What is an Actuator?

First things first. Let’s start this post by discussing first what exactly an actuator is. On a very basic level, actuators are components that work to control movement within a machine or motor. They’re commonly found in a variety of different types of motors, such as electric motors and stepper motors. They may also be found in cylinders.

Actuators are largely classified by the type of motion they create and what type of power source they operate on. In terms of the latter, actuators create either linear or rotary motion. Linear actuators create motion in a straight line, while rotary actuators create motion in a circular or rotational fashion. Linear actuators are commonly found in machinery that you might find in an industrial environment, where rotary actuators are typically found in smaller components. Rotary actuators are also commonly found in material handling equipment. In the next section, we’ll get into the various different types of linear and rotary actuators.

The Wide World of Actuators

While actuators can be very broadly defined as those that create either linear or rotary motion, there are various different types of these components. In this section, we’ll take a closer look at some of the more popular actuators you’re likely to find in industrial environments based on their source of energy.

Hydraulic Actuators

Hydraulic actuators typically work in a linear motion, and are commonly found in stepper motors as well as in applications that require clamping, opening, pressing and welding. They work by using hydraulic power to facilitate mechanical operation. While most hydraulic actuators are designed to create linear movement, they can create rotary motion as well. One of the big benefits of hydraulic actuators is their speed.

Pneumatic Actuators

Pneumatic actuators are ideal for applications that require very precise motion. They work by using a pressurized gas or compressed air to create mechanical movement, which can be either linear or rotary. Pneumatic actuators are commonly found in industrial automation machinery, notably material handling applications that need to transfer, pick, place, clamp or index. They typically offer high force and fast speeds in a compact footprint.

Electric Actuators

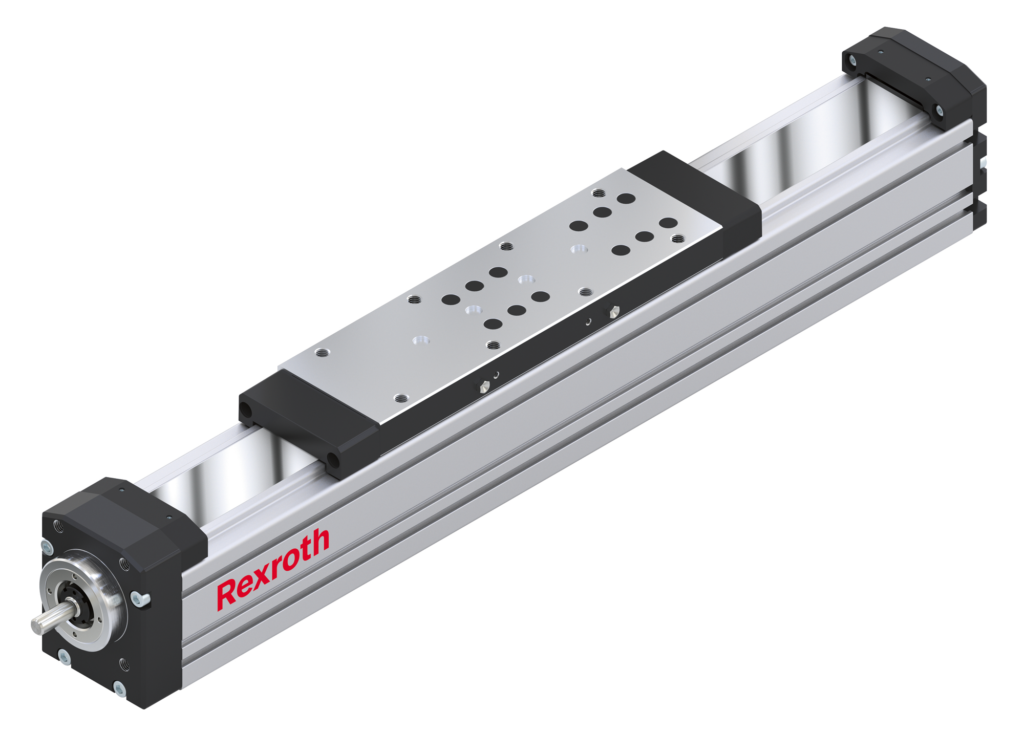

As the name implies, electric actuators work on electricity, and they’re often found in robotics equipment. Like pneumatic actuators, electric actuators can operate very precisely – often even more precisely than pneumatic actuators. They’re also very scalable, reprogrammable, and speed and force can even be customized to a certain extent. Because of this and their power source of electricity, electric actuators are among the most popular types of actuators used in industrial environments.

Electric actuators are also available in subcategories, including electromechanical and electrohydraulic. Contact us at JHFOSTER to learn more about what type of electric actuator is best suited for your application.

Other Types of Actuators

Hydraulic, pneumatic and electric actuators aren’t the only types of actuators that are available. Some other types of actuators include thermal and magnetic, mechanical and supercoiled. Though less common, each has their own place and could be ideal under the right set of circumstances.

Selecting the Right Actuator: What You Need to Know

There are three main things that you need to consider when it comes to selecting the actuator for your application: power source, movement and level of precision.

Like we said above, if electricity is widely available, then it makes sense to work with electric actuators. If electricity isn’t widely available, then hydraulic and/or pneumatic may make for a better selection.

Additionally, you need to know what type of movement you’re looking for and the actuator that is best equipped to deliver on it. All actuators create either linear or rotary motion, though some may create a combination of both.

Finally, how precise do you need the movement? Some actuators, such as hydraulics, have a much wider margin of error than others, like electric actuators. How accurately you need to function will have an impact on what type you acquire.

There are also safety and maintenance considerations that may make or break the type of actuator you select. Make sure you understand it all before making your selection.

Contact JHFOSTER Today

For more information on the various different types of actuators that are available and which ones might be best for your application, contact JHFOSTER today. As trusted experts when it comes to advising and supplying your facility with the right actuators to power its equipment the way that you need it, we’re here to advise you on the parts that will get the job done. Contact us today for more information and to get started.