Category: Air Compressor

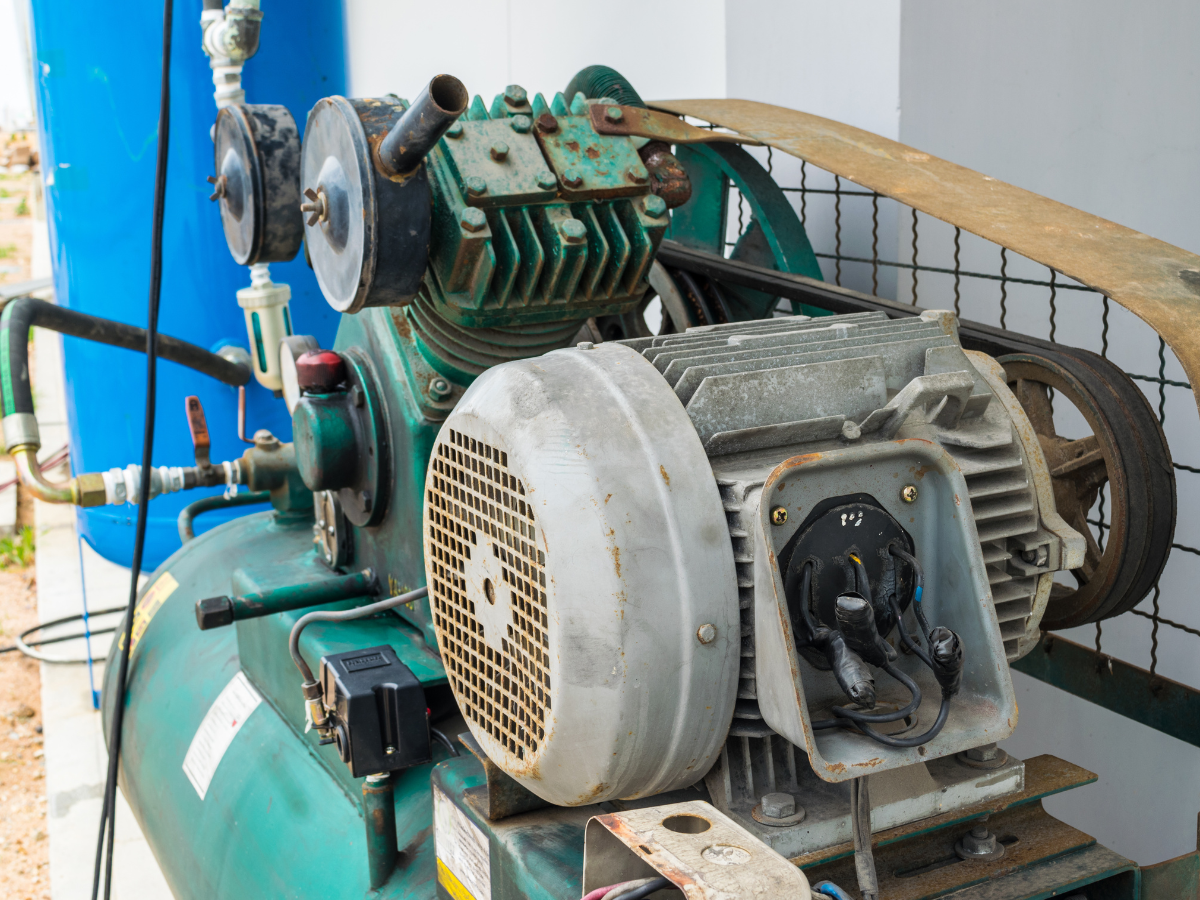

Piston Compressor Not Working? Troubleshooting Common Failures

A malfunctioning air compressor equals costly downtime, but JHFOSTER is ready to help you diagnose the most common causes of piston air compressor failure and guide you on the next steps to get your operation back online. Safety First: Before You Begin Safety is essential when working on your air compressor, so it’s important to […]

How to Calculate Air Compressor CFM

Correctly calculating your air compressor’s CFM requirement is the first step to ensuring that your pneumatic equipment will operate efficiently and reliably. This step-by-step guide will provide a formula for calculating the necessary CFM for your air compressor. What is an Air Compressor CFM Value? CFM stands for cubic feet per minute and represents the […]

A Practical Guide to Reducing Industrial Air Compressor Noise

A loud air compressor is more than just an annoyance; it’s a drag on productivity and safety. Fortunately, you can create a safer and more engaging work environment by tackling air compressor noise at its source. This guide provides actionable strategies, from simple maintenance to system modifications, to help you solve the problem and increase […]

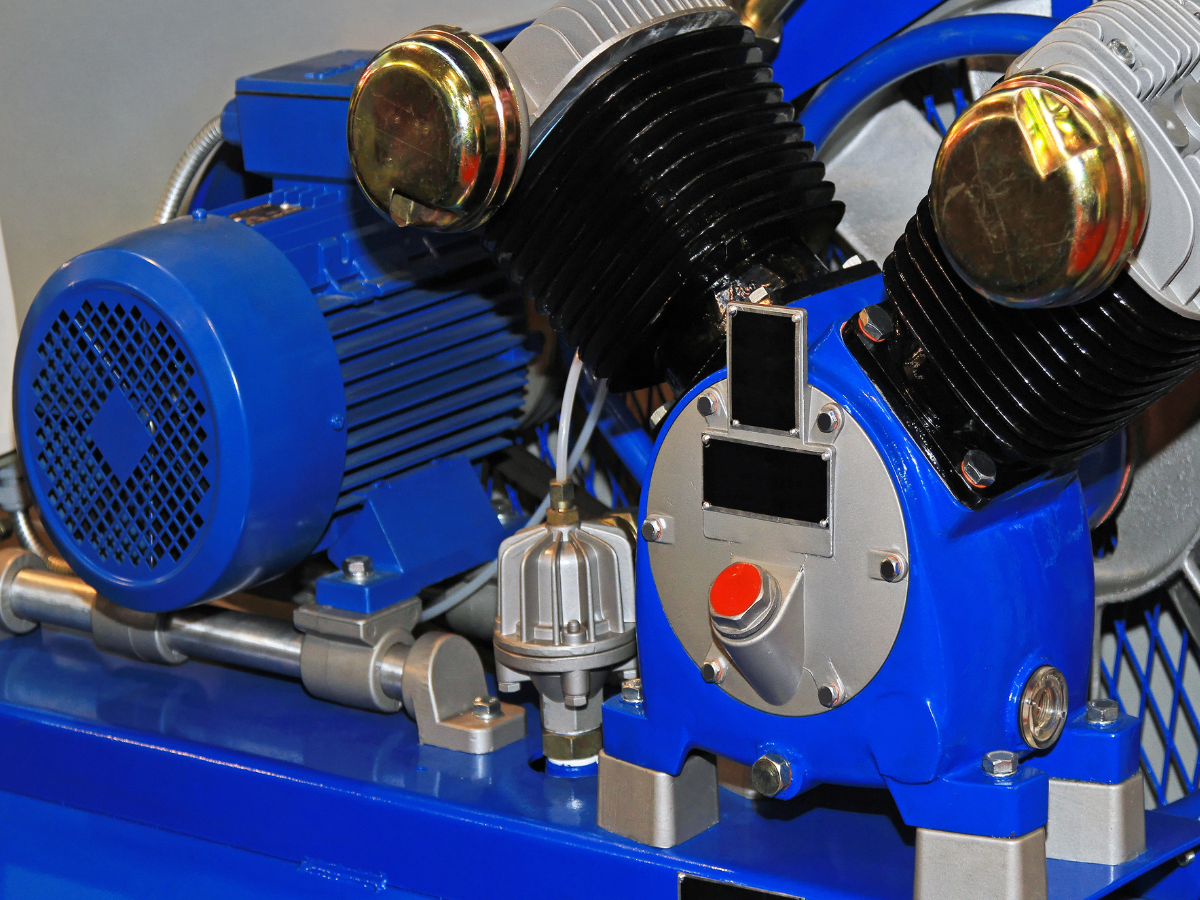

What is a 2-Stage Air Compressor?

Powering your pneumatic tools and production equipment efficiently and reliably depends upon choosing the right air compressor for your application. If you’ve been exploring the options, you’ve likely come across 2-stage air compressors. This blog will explain the technology, how it works and why a 2-stage compressor might be the ideal solution for your demanding […]

How to Maintain Your Air Compressor Motor for Peak Performance

Because your air compressor is an integral part of daily operations, maintaining your unit’s motor is essential. Proper air compressor motor maintenance reduces the risk of equipment failure and associated downtime, extends the life of your air compressor and helps maximize the energy efficiency of your air compression system. As your partner in air compression […]

Reciprocating-Type Air Compressor Won’t Build Pressure? Common Causes & How to Fix Them

When your piston air compressor runs, but won’t build pressure, your entire operation can grind to a halt, resulting in downtime, lost productivity and reduced efficiency that negatively impact the bottom line. This blog will help you identify common causes and potential solutions. Whether it’s a simple adjustment or a more complex mechanical failure that […]

A Guide to Choosing the Right Oil for Your Industrial Air Compressor

Using the correct type of oil in your air compressor is essential for ensuring the reliability, performance and longevity of your industrial compressed air system. Your air compressor is a critical asset and protecting it starts with proper maintenance, including choosing the right oil. To help you determine what type of oil your air compressor […]

A Guide to Industrial Applications for Compressed Air Systems

How is compressed air used in industry? These versatile machines turn ambient air into energy that is used to operate pneumatic tools and equipment in numerous sectors, ranging from general manufacturing to food and beverage processing to automotive repair and assembly to mining. No matter what industry you’re in, you can be sure there’s a […]

Preventing Contamination in Industrial Compressed Air Systems

Industrial air compressors keep manufacturing operations in business, so contamination in the system is unacceptable. Compressed air contaminants, such as water, oil, particulates and microorganisms, can degrade compressed air quality and lead to decreased system efficiency, operational safety hazards and contaminated end products – all of which are bad for the bottom line, making contamination […]

Optimize Compressor Health with an Air Compressor Monitoring System

Compressed air is often cited as the fourth utility for businesses that rely on the resource for daily operations, so experiencing air compressor downtime can create a costly problem for manufacturers. However, a good air compressor monitoring system gives users the power of remote equipment monitoring and provides visibility into the compressor room, allowing optimization […]