Category: Compressed Air

Oil-Free and Oil-Less Air Compressors Support Sustainability

While oil-free and oil-less air compressors were traditionally adopted by industries that require the purest compressed air to ensure quality and safety in sensitive products, it turns out going oil free air can help all manufacturers reach green initiatives and sustainability goals, as oil-free and oil-less compressors minimize oil waste and energy usage to help […]

Best Practices for an Efficient Compressed Air Distribution System

If your facility has been experiencing pressure drops in the compressed air supply and higher than normal electric bills, the culprit may be the compressed air piping system. In fact, issues within the distribution system can greatly influence system performance and efficiency. Applying best practices to the compressed air piping system will ensure that sufficient […]

Air Dryers: The Secret Weapon of the Compressed Air System

Air dryers are essential to removing moisture and humidity – byproducts of the air compression process – from the treated air. By doing so, they safeguard the compressed air system, pneumatically operated equipment and even finished products against contamination and corrosion, making air dryers the secret weapon of industrial facilities that rely on air compressors […]

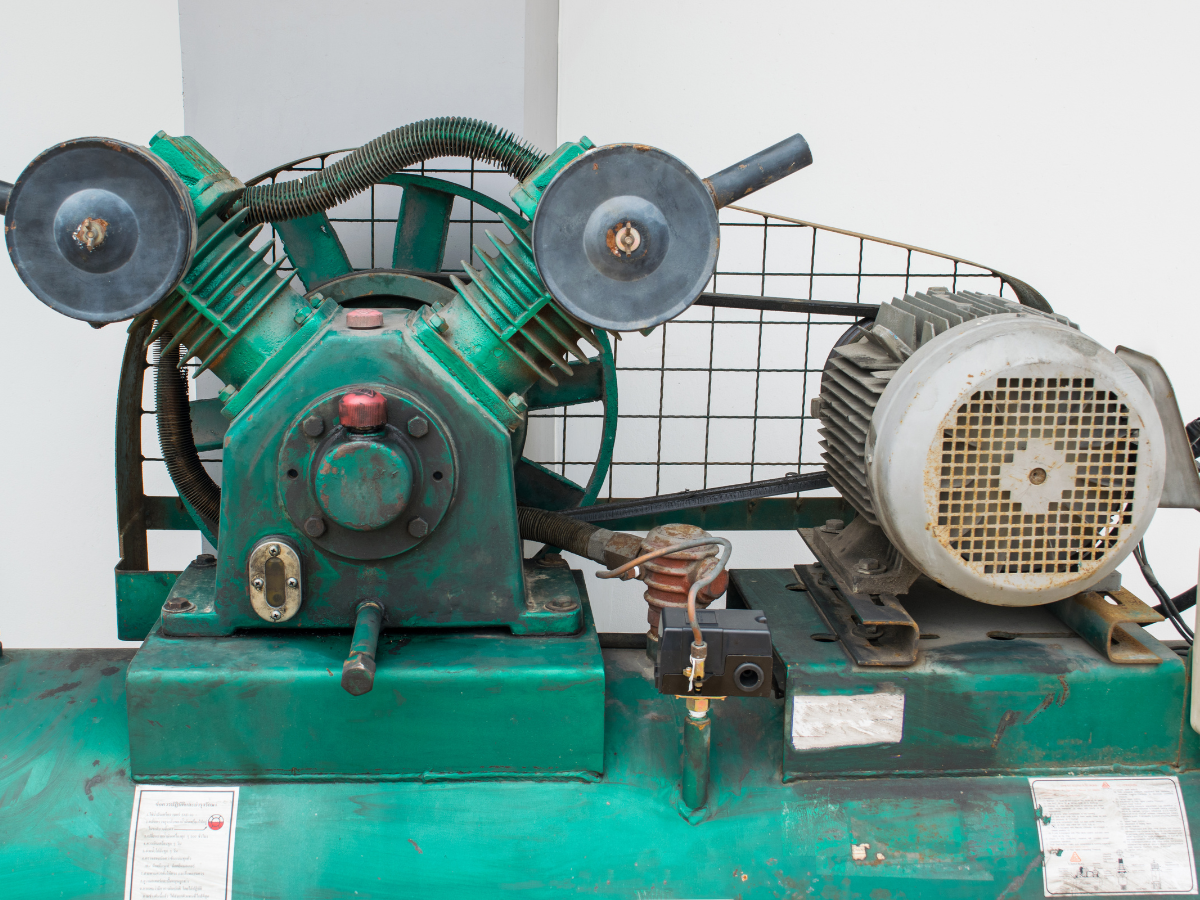

Decoding Air Compressor CFM Calculations

An air compressor serves as the heart of most industrial facilities as it converts electricity into pressurized air that powers the pneumatic tools and equipment used for production. For this reason, it’s essential to understand the key specifications when selecting or operating an air compressor and one of the most misunderstood performance indicators is the […]

3 Things to Know When Sizing an Air Compressor

Properly sizing an air compressor can make you feel like Goldilocks – one air compressor may be too big (leading to increased operating costs due to wasted energy) and another may be too small (resulting in inadequate airflow to equipment and problems with production). So, how do you find the air compressor that is “just […]

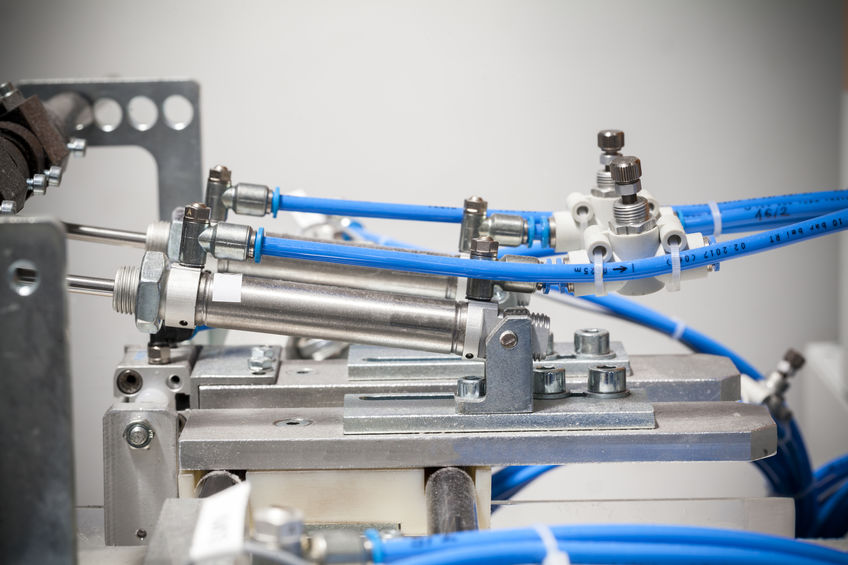

6 Essential Components of a Pneumatic System

Pneumatic systems use pressurized air to generate motion in many industrial applications, such as air-powered tools, end of arm tooling on robots, automated equipment and motion control systems. Pneumatics are widely used throughout industry and manufacturing because they are an effective, efficient and safe means of achieving movement and control. However, for pneumatic systems to […]

Pneumatic Systems: A Perfect Fit for Industrial Applications

Pneumatic, or compressed air-driven, systems have been used to achieve mechanical motion in industrial machinery for over 100 years and, in more recent times, pneumatic systems have advanced, expanding the range of pneumatic applications to include robotics, automated industrial equipment, processes and motion control in a variety of industries. The popularity of pneumatics stems from […]

Long Live Your Air Compressor

Air compressors serve as the heart of the compressed air system in many industrial facilities where they likely power everything from air-operated tools to valves to automated equipment. While proper preventive maintenance can go a long way toward keeping the heart of your operation beating for years to come, air compressors will eventually need repair […]

Pneumatic Systems: 101

Chances are if you work in an industrial facility, you’ve handled tools and equipment that are powered by a pneumatic system. These simple, yet powerful systems use clean, dry compressed air to create mechanical motion that powers tools, machinery and industrial automation systems. Learning about the components involved in a pneumatic system and how they […]

Troubleshooting 7 Common Causes of Piston Air Compressor Failure

Compressed air is often dubbed as the “4th utility” in industrial facilities because it powers essential tools, machines and processes; however, heavy use of air compressors subjects them to wear and tear that will more than likely result in operational issues and potential failure at some point during the lifetime of the asset. The expense […]