6 Essential Components of a Pneumatic System

Pneumatic systems use pressurized air to generate motion in many industrial applications, such as air-powered tools, end of arm tooling on robots, automated equipment and motion control systems. Pneumatics are widely used throughout industry and manufacturing because they are an effective, efficient and safe means of achieving movement and control. However, for pneumatic systems to provide optimal performance, they must include the correct components. Here, we focus on the six parts that are essential to a properly functioning pneumatic system.

6 Essential Pneumatic Components

While pneumatic systems rely on a variety of components, these six are integral to providing movement and control in industrial applications:

- Air compressor: Pneumatic systems rely on air compressors to draw in air from the surrounding atmosphere and compress it. As the air volume decreases, it becomes pressurized so that it can later be used as the force that creates movement in the equipment it supplies. The intake air is filtered before entering the compressor and again before it enters the pneumatic system to ensure that it is clean and dry.

- Air reservoir: This component is used to store the treated compressed air until it is needed. They are a necessary part of most industrial pneumatic systems primarily because the compressed air flow required to power them is rarely constant. A reservoir with regulated output flow serves as a buffer between the compressor and plant operations. When properly sized it will provide steady plant pressure under varying flow conditions, resulting in consistent performance from pneumatically powered tools and equipment and reducing wear and tear on the compressor controls. In other words, the reservoir serves as a storage point for prepared compressed air so that it is ready for immediate delivery and can provide near-instant machinery activation.

- FRL (Filter-Regulator-Lubricator) The FRL provides treatment of compressed air at the point-of-use. The filtration removes particulate, moisture and sometimes harmful vapor that may be present. The regulator should be set at the pressure recommended by the machine or tool manufacturer and below the minimum plant pressure to assure proper and consistent operation. In some applications a lubricator is recommended to provide light lubrication to the compressed air which can increase control valve and actuator lifespan in some high cycle rate applications. Finally, in many cases a shut-off isolation valve is added to the FRL to meet safety requirements.

- Pneumatic valves: In a pneumatic system, valves are used to control and regulate the amount and direction of the airflow to the equipment or machinery. They are essential for proper operation and control of pneumatic systems.

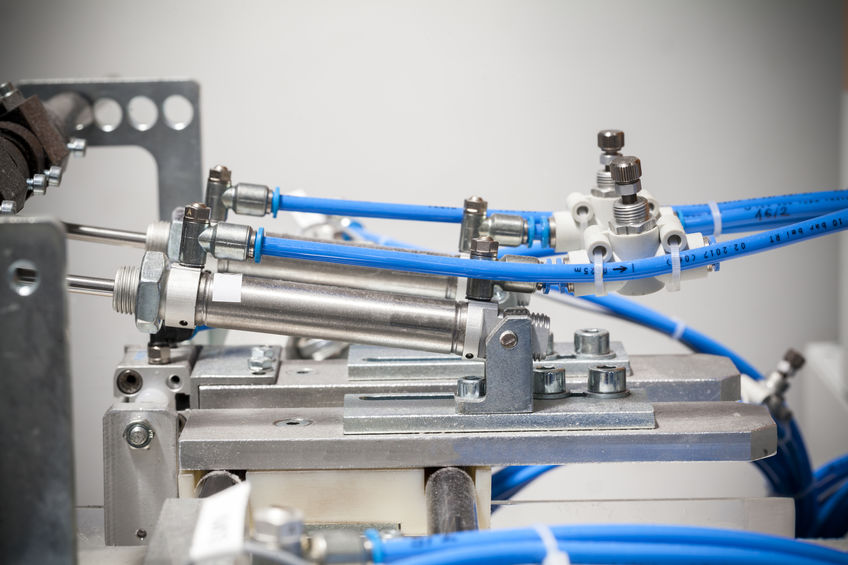

- Pneumatic circuit: As with electronic systems, pneumatic systems require a properly designed circuit to operate safely and effectively. But instead of using wires and connectors, pneumatic circuits use piping, tubing and fittings to distribute the compressed air to the various components within the system. A well-designed pneumatic system will provide consistent, trouble-free operation for many years

- Pneumatic cylinders/actuators: There are a large variety of types and configurations available but pneumatic cylinders are a commonly used pneumatic actuator.

The Benefits of Pneumatic Systems

Because of the simplicity of pneumatic systems, they are a mainstay in most industrial and manufacturing facilities. The most notable benefits of pneumatics in these applications include:

| Cost-effectiveness | Pneumatic components themselves are typically inexpensive, which reduces the overall cost of the system. In addition, because they are simple to operate and durable, the components and system rarely require costly or time-consuming maintenance procedures. |

| Reliable and flexible performance | The design of a pneumatic system is simple and the components are reliable and uncomplicated, making them suitable for use in the dirty, corrosive, high-temperature environments usually found in industrial facilities. In addition, because airflow and pressure can easily be adjusted and controlled by pneumatic valves, they can be used in a variety of applications throughout the facility. |

| Safe and environmentally friendly | Because pneumatic systems rely on compressed air, not electricity, to generate motion in industrial tools and equipment, they can be applied safely and without concern in hazardous areas where there is typically a risk of fire or explosion. In addition, when air is expelled after use, it can be released back into the atmosphere without additional treatment or cleaning. |

By capturing atmospheric air and turning it into reliable, stable, clean, motion-inducing energy, pneumatic systems are a cost-effective, safe and reliable way to power industrial equipment. To learn more about the components of a pneumatic system or for assistance selecting appropriate pneumatic components, please contact JHFOSTER.