Category: Pneumatic Automation

7 Ways Pressure Flow Controls Optimize Pneumatic Systems

While most facilities with properly sized air compressors should have an adequate supply of air to power their automated pneumatic systems, problems may arise during fluctuations in demand and times of peak usage when air demand exceeds capacity, causing unstable system pressure. In response to fluctuations, the pneumatic system can overcompensate and boost system pressure […]

Optimizing Pneumatic System Design for the Best Performance

In pneumatic systems, pressurized air generates motion that is used to drive automated equipment, manufacturing processes and air-powered tools and devices in a reliable and cost-effective way. But to achieve top-notch performance in any application, properly designed air systems are a must. This blog will explore and explain pneumatic systems and how careful selection of […]

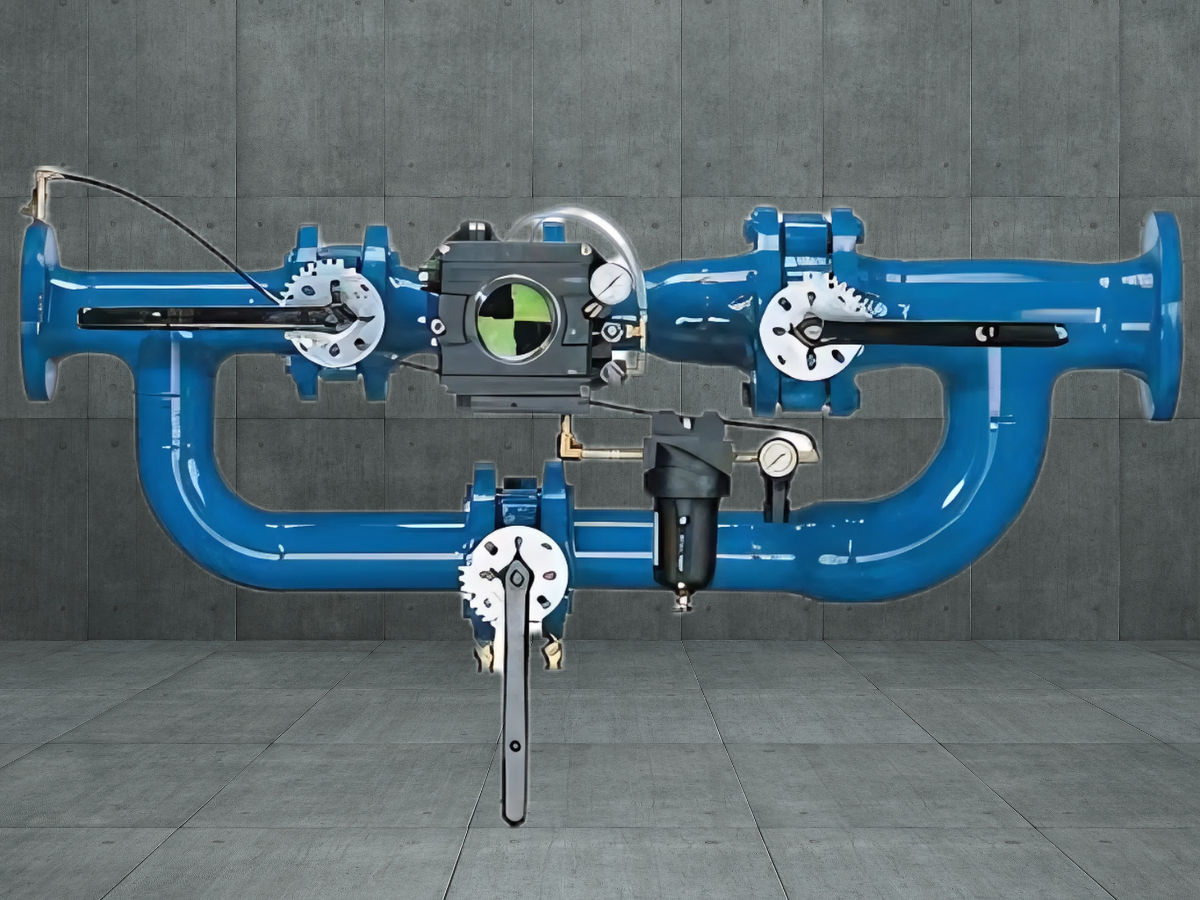

Choosing the Right Flow Control Valve Maximizes Performance

Although the importance of flow control valves is often overlooked, they are a critical component in industrial systems as they regulate and direct the flow, volume, rate and pressure of liquids or gases through piping systems and directly impact the safety and efficiency of the plant. While selecting an appropriate flow control device may seem […]

Automation in Action: 4 Real-World Applications for Pneumatic Systems

Pneumatic systems rely on compressed air, a few simple components and an arrangement of tubes or piping to bring motion and movement to machinery, equipment and tools. Their straightforward, clean and low-cost source of power makes pneumatic systems an attractive option across many sectors and, as a result, more engineers are specifying them for automation […]

3 Ways Pneumatic Control Valves Support Sustainability Efforts

While the main objective in any manufacturing facility is to produce product, minimizing a plant’s environmental footprint and advancing sustainability efforts are undoubtedly growing corporate concerns. For this reason, there has been a strong emphasis on improving the efficiency of pneumatically driven processes. While there are many ways to reduce the energy consumption of pneumatic […]

Troubleshooting Common Pneumatic Control Valve Issues

As part of a pneumatic system, pneumatic control valves play the important role of controlling the flow of compressed air within the system; therefore, minor issues with control valves can have a significant impact on the operation of the overall system. When pneumatic control valves malfunction it can cause upsets that slow down or stop […]

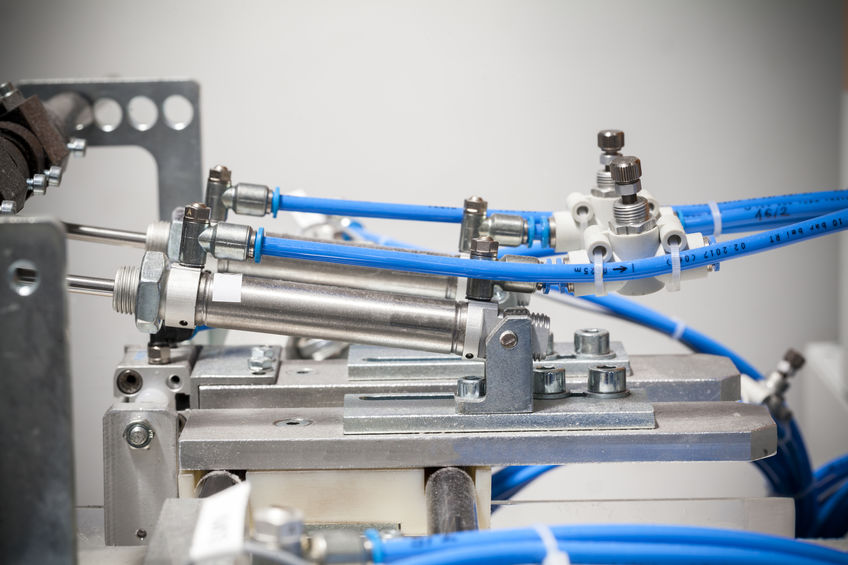

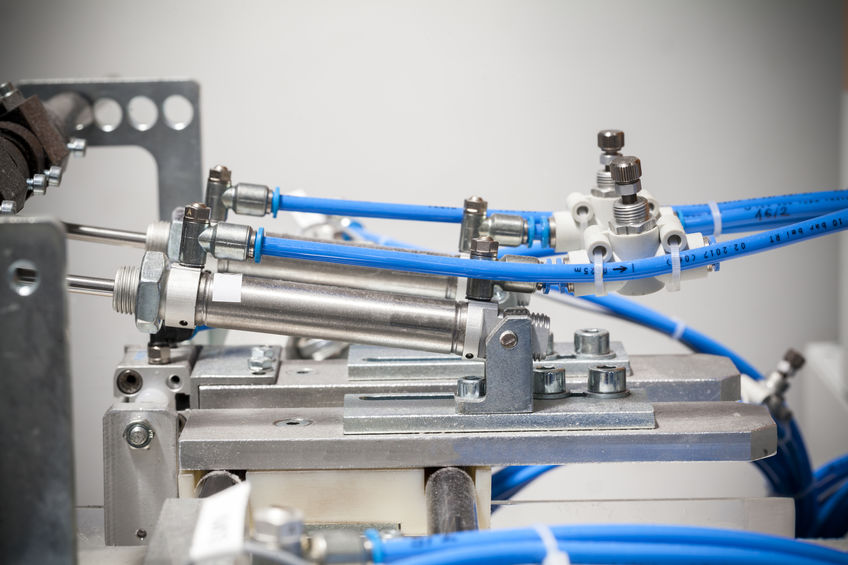

6 Essential Components of a Pneumatic System

Pneumatic systems use pressurized air to generate motion in many industrial applications, such as air-powered tools, end of arm tooling on robots, automated equipment and motion control systems. Pneumatics are widely used throughout industry and manufacturing because they are an effective, efficient and safe means of achieving movement and control. However, for pneumatic systems to […]

Pneumatic Systems: A Perfect Fit for Industrial Applications

Pneumatic, or compressed air-driven, systems have been used to achieve mechanical motion in industrial machinery for over 100 years and, in more recent times, pneumatic systems have advanced, expanding the range of pneumatic applications to include robotics, automated industrial equipment, processes and motion control in a variety of industries. The popularity of pneumatics stems from […]

Top Five Advantages of Industrial Automation

Automation has become a vital tool for industrial facilities that need to improve productivity in the workplace. But did you know there are other advantages as well? For those manufacturers who are slow to adopt automation, this blog will explain the ways in which automation helps manufacturers and other industrial businesses streamline production, enhance quality, […]

Understanding Your Pneumatic System Components

Industry relies heavily upon pneumatic systems to power tools, automated equipment and machines throughout the plant, so having a basic understanding of the components and working principle can go a long way toward maintaining efficient operation of these advantageous systems. Simply put, pneumatic systems provide an uncomplicated, economical and reliable way to make things move. […]