Automation in Action: 4 Real-World Applications for Pneumatic Systems

Pneumatic systems rely on compressed air, a few simple components and an arrangement of tubes or piping to bring motion and movement to machinery, equipment and tools. Their straightforward, clean and low-cost source of power makes pneumatic systems an attractive option across many sectors and, as a result, more engineers are specifying them for automation projects. As a matter of fact, pneumatic systems can be found in a myriad of applications across a broad range of industries. Here, we will explore why pneumatic systems are so popular and look at four real-world applications that showcase the scope of pneumatic systems.

Pneumatic Systems: 101

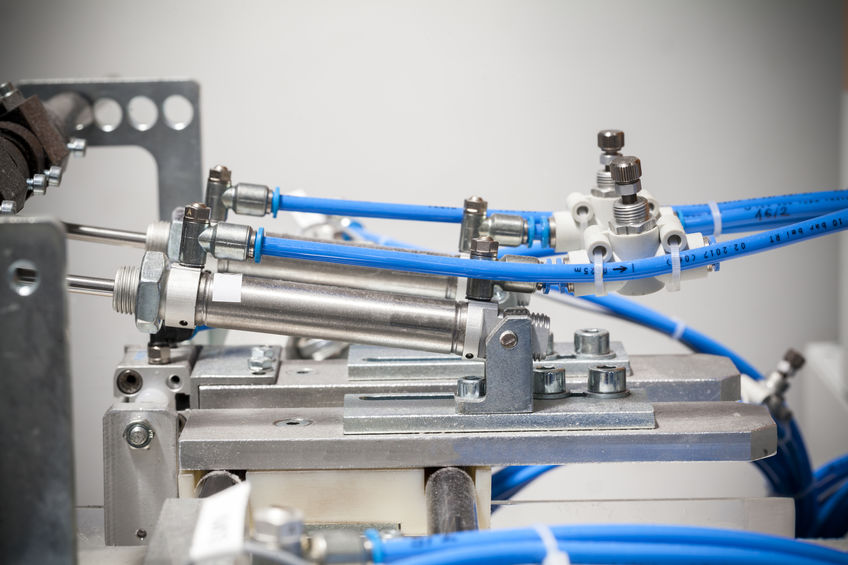

Pneumatic systems rely on multiple components to control and maintain airflow to provide a consistent source of power to devices. Within the system, an air compressor takes in ambient air and compresses it into a smaller volume. The pressurized air then passes through a filtration system and, likely, an air dryer to remove contaminants and moisture. Next, treated air is distributed through a series of valves that control, maintain and direct the airflow through the distribution system of pipes and tubing until the compressed air reaches the system actuator, which creates motion in connected devices such as air-powered tools, robot end of arm tooling or automated machinery. Typical pneumatic system motion profiles include lifting, holding, closing, opening, pushing and/or pulling.

There are several advantages to using pneumatic systems in automation projects, including:

- Reliability: Because pneumatic systems rely on simple components, are not affected by changes in temperature and are resistant to shock and vibration, the systems tend to be highly reliable in operation. Additionally, pneumatic systems provide a consistent source of power because air is readily available.

- Cost-Effectiveness: Pneumatic systems consist of low-cost components, are simple to install and require very little maintenance. In addition, ambient air is free for the taking from the atmosphere. These factors make pneumatic systems one of the lowest cost power options available.

- Safety: Because pneumatic systems power equipment using air, they do not generate sparks, which reduces the risk of fire or explosion in environments where it may be a concern.

- Flexibility: One pneumatic system can be used to provide precise and consistent control of several components/applications, reducing the need for additional power sources and making pneumatics an efficient means to power multiple devices. In addition, pneumatic systems are easy to customize and can be designed to operate in a range of applications from heavy-duty equipment to small, delicate robotics.

- Cleanliness: Unlike hydraulic systems which are notorious for leaking fluids, pneumatic systems provide a cleaner source of power. While there may be leaks from a pneumatic system, any air leakage will simply return to the atmosphere. In addition, specialized oil-free or oil-less air compressors and the proper filtration system can produce treated air that is clean enough to meet stringent standards in sterile industries such as food and pharmaceutical processing.

Real-World Pneumatic System Applications

With all the advantages pneumatic systems offer, it’s not surprising that they’re used in a wide variety of automated applications, including material handling, packaging, conveying and filling equipment, throughout industries such as general manufacturing, automotive manufacturing and food and beverage processing. Below we highlight four examples of pneumatic systems in action that showcase their versatility.

| Food Processing Equipment | Among other things, food industry uses for pneumatic systems include equipment for chopping, cutting, slicing and dicing machines where pneumatic cylinders provide precise control of pressure and motion to reduce damage to food items. For example, air-driven saws, knives, blades and mandolins can be used to chop, dice or slice delicate foods such as cheese and baked goods prior to packaging or fruits and vegetables in preparation for canning or freezing. Pneumatic-based cutting systems can be easily adapted to process a variety of sizes, thicknesses and angles and are precise enough to encourage uniformity. |

| Robotic Arms | Used throughout various segments of the manufacturing industry, robotic arms utilizing pneumatically operated end of arm tooling (EOAT) can be applied to assembly, pick and place, machine tending, and material handling tasks, among others. Thanks to advances in pneumatics and vacuum that allow for precise control of speed and motion and permit more fluid movement, pneumatic systems are commonly used to operate robotic EOAT. The simple, lightweight design of pneumatic systems is easier, often cheaper and less time consuming to maintain than electronic systems; pneumatics including vacuum EOAT can be precise, repeatable and provide fluid motion so they will not damage delicate products; and pneumatics work well in both hot and cold temperature extremes, making them ideal for operation in applications with extreme temperature requirements. |

| Producing PET bottles | As many plastic producers are turning to stretch blow molding processes for the production of PET bottles, pneumatics are finding use in this automated equipment because it offers a low-cost, flexible, precise and repeatable motion profile. In the machines used for stretch blow molding, PET preforms are mounted on cores and moved through an oven to soften them. Next, they are inserted into molds that shape them into bottles and high-pressure air is blown on them to set the shape and begin the cooling process. In this application, pneumatics control the cores as they move through the heating, stretching and blowing and pneumatic control valves are used during the expansion blowing process. |

| Automotive Painting | Automotive manufacturing relies on pneumatics for many operations, but one of the most important is the painting and finishing process. Prior to painting, bare vehicles are cleaned using dry, oil- and contaminant-free compressed air to remove any impurities that may have adhered during manufacturing. Following cleaning, oil-free, clean, dry compressed air is used to mix and prepare the paint to ensure even distribution of pigment. Finally, using compressed air as the power source, the paint is sprayed though guns, robots or paint sprayers onto the prepared car body. In these operations, the pneumatic system provides high-quality, moisture-free compressed air that helps achieve a smooth, even factory finish. |

Representatives at JHFOSTER are available to discuss the use of pneumatic systems in your next automation project.