Category: Air Compressor

5 Misconceptions About Oil-Free Air Compressors

Oil-free air compressors are growing in popularity. In industries such as pharmaceutical, food, medical device, and electronics manufacturing, they have become a staple. Other industries employ them in an effort to avoid oil vapors that can damage sensitive production equipment or because oil-free compressors are reputed to reduce maintenance needs. While they do offer the […]

Strategies for Running an Efficient Compressed Air System

In industrial facilities, compressed air is a widely used resource because it’s a safe and readily available form of power for operating machine tools, material handling equipment and other pneumatic powered machinery. However, if not properly designed, operated and maintained, it can be a major facility expense as it requires 8 hp of electricity to […]

The Importance of Medical Compressed Air During the Pandemic

Medical compressed air has always played an important role in hospitals, intensive care units and emergency rooms where respiratory air is supplied to patients via machine ventilation and other equipment; however, the worldwide health crisis of COVID-19 intensified the need for high-quality, high-purity medical compressed air that was clean and free of humidity, oil, dust […]

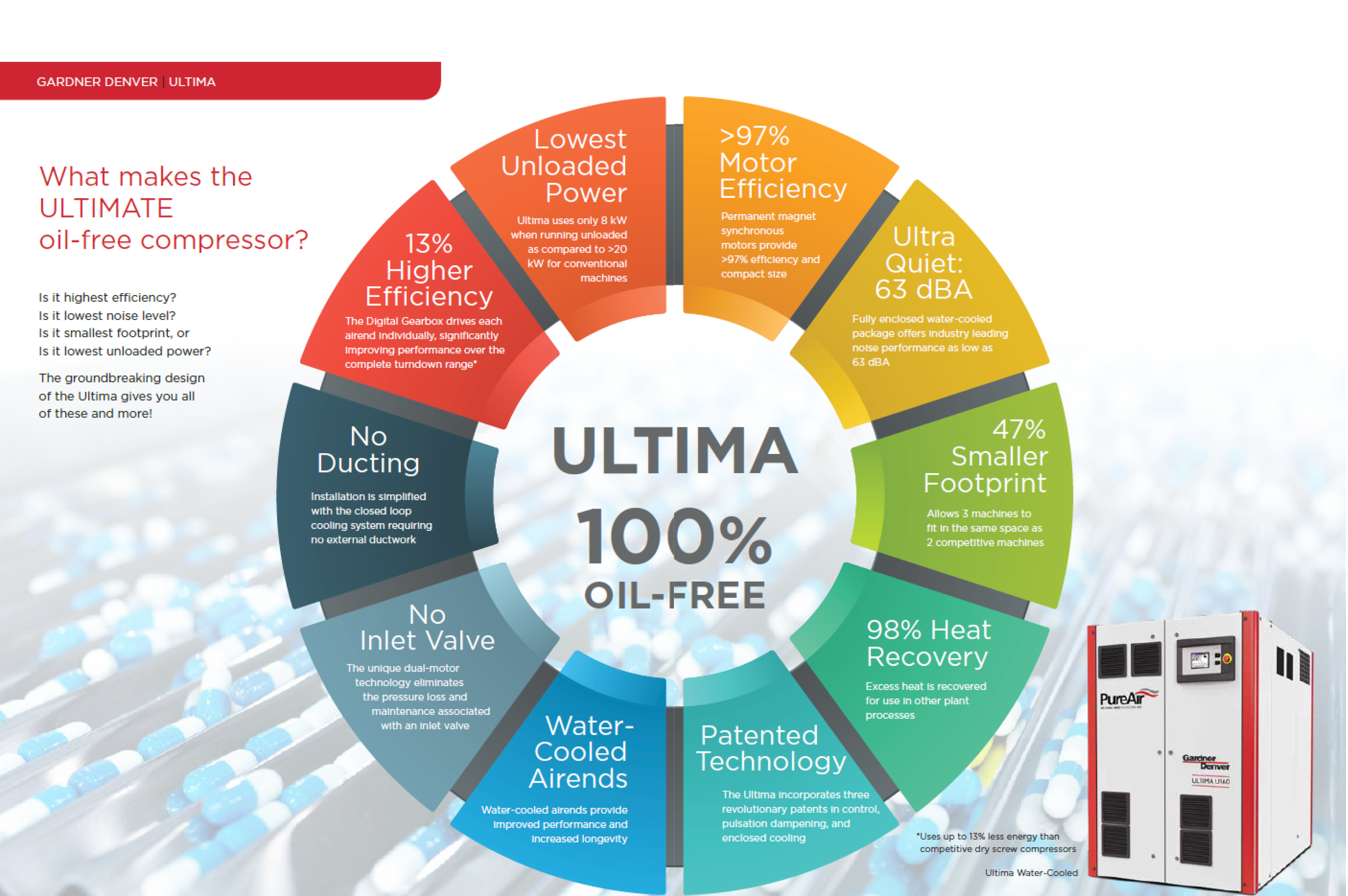

What are the Advantages of Oil-Free Air Compressors?

Oil-Free Air Compressors either have no mechanical contact inside the compression chamber or use alternate materials to protect the mechanism without lubrication. Many Oil-Free Air Compressors use materials such as water or a Teflon coating to keep the mechanism running smoothly. Some Oil-Free Air Compressors do contain oil. Oil will not be in contact with the compression chamber. […]

How to Tell When Your Compressed Air System Needs New Filters

Using clean dry air is beneficial for compressed air systems in many ways. It will reduce wear and tear and maintenance required for pneumatic tools, machines, and devices used in the manufacturing environment and help maintain product quality and consistency. You can reduce machine downtime by having the proper filtration system in place while also […]

Maximizing Air Compressor Efficiency Improves the Bottom Line

Because compressed air is widely used in industrial facilities, improving air compressor efficiency can create a competitive advantage as it will not only generate cost savings that will boost the bottom line, but it can also help your facility improve quality and achieve sustainability goals. While U.S. Department of Energy (DOE) statistics show that compressed […]

Optimizing Your Air Compression System Reduces Costs

Operating an air compression system consumes a significant amount of energy, so any improvements in efficiency will result in a better bottom line. For this reason, it is beneficial to evaluate and maintain your air system on a regular basis. In addition to ensuring that your air compression system uses less energy, regular compressed air […]

Air Compressor Maintenance Boosts Energy Efficiency

Air compressors are hard-working fixtures in most industrial facilities, yet they are often neglected when it comes to routine maintenance. This can be a costly mistake! Not only does regular maintenance improve performance, but it also promotes energy efficiency. While statistics show that power consumption accounts for about 70% of an air compressor’s cost over […]

Preventive Maintenance Prolongs the Life of Oil-Free Compressors

One of the reasons manufacturers are turning to oil-free air compressors is that they require minimal maintenance; however, it’s important to remember that they are not entirely maintenance-free. As a matter of fact, preventive maintenance on oil-free air compressors is necessary to ensure that the unit remains operational for years to come. Here, we suggest […]

Common Compressed Air Service Questions, Answered

We’ve all been there…the heart of your air system and possibly your facility – the air compressor – is acting strange and you aren’t sure why. Possibly it’s losing pressure or perhaps you’ve noticed that it’s running more often than usual. Unexpected breakdowns and issues can wreak havoc on operations and production, so it’s best […]