Using ISO 8573-1:2010 to Ensure Compressed Air Purity Levels

Often called “the fourth utility,” compressed air systems are used throughout the manufacturing industry and serve many functions within a facility. They drive pneumatic equipment used on items such as conveyors that move product from place to place; run tools, machines and other equipment essential to production and power packaging systems that keep finished product fresh or protected during storage and shipment.

When the compressed air system is properly maintained, the provided air is a safe and clean power source; however, contaminants such as particles, water and oil can breach the system and reduce compressed air quality. Contaminated air may adversely affect product quality, which creates scrap and is especially problematic in industries such as food and beverage and medical device manufacturing. In general industry, contaminants may damage machinery, causing unplanned downtime.

In all industries, low-quality compressed air negatively impacts energy efficiency. As a matter of fact, inefficient and poorly maintained compressed air systems are responsible for an estimated $3.2 billion in unnecessary utility payments, according to the Compressed Air and Gas Institute. For these reasons, it is critical that the air quality in your compressed air system is at the purity levels necessary for the application.

Compressed Air Contaminants

Contaminants find their way into a compressed air system in a variety of ways. The three main contaminants of concern, according to ISO Standard 8573-1:2010, include solid particulates, water (liquid and vapor) and oil (liquid and vapor).

Solid particulates, such as airborne particles from the surrounding air, solid particles associated with pipe scale and wear particles from the compressor itself, can be introduced into the compressed air system.

Water or moisture contamination can be introduced into the system also. It is often a result of humidity in the surrounding air, which is drawn into the compressed air system via the intake of the air compressor. Moisture contamination may spoil sensitive products, wreak havoc on pneumatic equipment and encourage bacterial growth in compressed air piping.

Oil particulates, including liquid, aerosol and vapor, often come from an oil-flooded air compressor. Even with oil-less air compressors, carbon vapors, small hydrocarbons and CO, CO2, SO2 and NOx, can enter through the air intake and contaminate the system.

Using ISO Standard 8573-1:2010 to Achieve Industry-Specific Compressed Air Quality

ISO 8573-1:2010 is the international standard used by compressor and filter manufacturers and testing laboratories and is applied across manufacturing facilities to ensure high-quality compressed air. Within the multi-part standard, Part 1 classifies the contaminant type (solid particulate, water and oil) and provides air quality levels for each, while Parts 2 through 9 outline testing methods for measuring contaminants. The standard offers guidance for General Manufacturing (ISO 8573-1:2010 1.4.2), Food and Beverage Manufacturing (ISO 8573-1:2010 1.2.1) and Medical Device Manufacturing (ISO 8573-1:2010 Class 0), among others.

The standard explains: The three major contaminants in compressed air are solid particles, water and oil, which are categorized by compressed air purity classes. The compressed air purity classes group the concentrations of each of the contaminants into ranges, with each range given its own purity class index.

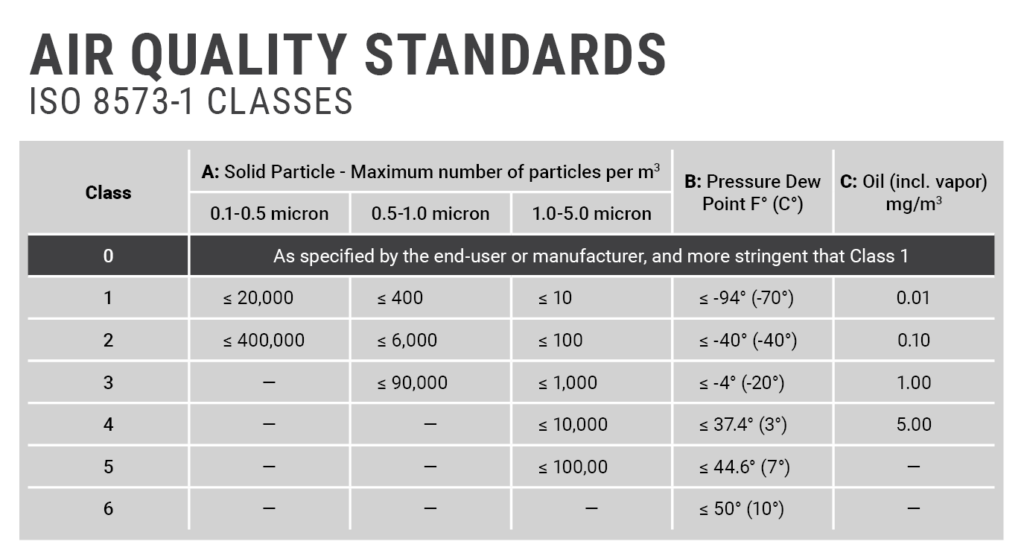

Within the standard, an Air Quality Classes Chart provides these ranges in an easy-to-read format. According to the chart, Class A measures solid particles contained in the compressed air stream. Within this column are three sub-columns that identify the amount of permissible particles by micron size. Class B measures dew point, or the maximum allowable amount of water vapor and liquid, in the compressed air system. Class C measures total permissible oil content, including aerosol, liquid and vapor, in the compressed air.

Certain industries and applications are required to meet specific air quality levels, according to the standard. When specifying the air purity requirement for an industry, the standard (ISO 8573-1:2010) is referenced first, followed by the purity class for each contaminant.

For example, general industry falls under ISO 8573-1: 2010 Class 1.4.2. The three digits following the standard refer to the purity classifications needed for solid particulate, water and total oil, in that order. So, selecting an air purity class of 1.4.2 for general industry means:

- Class 1 levels are needed for solid particulate. Therefore, in each cubic meter of compressed air, the particulate count should not exceed 20,000 particles in the 0.1-to-0.5-micron size range, 400 particles in the 0.5-to-1 micron size range and 10 particles in the 1-to-5 micron size range.

- Class 4 levels are needed for water, meaning a pressure dewpoint of 37.4°F or better is required and no water or liquid vapor is allowed.

- Class 2 levels are required for oil, meaning in each cubic meter of compressed air, not more than a total of 0.1 mg/mp of oil, including liquid, aerosol and vapor, is permitted.

Industries such as food and beverage processing have more stringent guidelines because the products will be consumed. Food and beverage production generally falls under ISO 8573-1:2010 Class 1.2.1. Here:

- Class 1 levels are needed for particulate. Therefore, in each cubic meter of compressed air, the particulate count should not exceed 20,000 particles in the 0.1-to-0.5-micron size range, 400 particles in the 0.5-to-1 micron size range and 10 particles in the 1-to-5 micron size range.

- Class 2 levels for water must achieve a pressure dewpoint of -40°F or better and no liquid water is allowed.

- Class 1 levels for oil means that food and beverage processors must maintain levels of no more than a total of 0.01 mg/m3 of liquid oil, oil aerosol and oil vapor.

Class 0 applies to industries such as medical device manufacturing. It does not mean zero contamination; however, Class 0 levels are more stringent than Class 1 due to the highly sensitive nature of these products. Class 0 requires the user and the equipment manufacturer to agree to contamination levels as part of a written specification. Those levels should be within the measurement capabilities of the test equipment and methods discussed in Parts 2 through 9 of the standard.

Meeting ISO 8573-1:2010 for Your Industry

Determining the purity class for each of the three main contaminants that is appropriate for a particular industry/application is the first step in meeting the compressed air quality standards. From there, the means of testing, as specified in Parts 2 through 9, will ensure that your current air quality is meeting these purity levels. Testing includes point testing for particles, dew point (water) and oil through a variety of test methods and laboratory analysis.

If analysis finds that you are not meeting the required purity level for your industry or you need to surpass these requirements for highly sensitive products, equipment upgrades may help improve compressed air quality.

Depending on the application, compressor technology may vary considerably. Industries such as food and beverage and medical device manufacturing may benefit from an oil-free compressor, which does not use oil for lubricating. Instead, wearable parts are friction coated with specialty ingredients and are self-lubricating, reducing the chances of oil entering the compressed air system.

Filtration is key to providing clean compressed air in any industry but is especially important when manufacturing food and beverage or medical devices. Two types of filter technologies are: Particulate filters and oil filters. Filtration intended to remove particulates is usually designed to the required level of the industry where it will be installed. Oil filters are also available to help remove lubricant contaminants from compressed air systems. Always ensure that the chosen filtration meets the classification purity levels necessary for your industry. General manufacturing, food and beverage processing and medical device manufacturing will have vastly different filtration needs. Also keep in mind that purchasing appropriate filters is not enough. They must be regularly inspected, cleaned and replaced to keep high-quality compressed air flowing from the system.

Air dryers are installed to lower the dew point of the compressed air so that condensation is reduced or eliminated. They should be properly sized for the compressed air system as they are energy intensive and over drying compressed air will increase electricity consumption of the compressed air system.

Once purity levels are established and achieved through installation of proper equipment, the system should be monitored to guarantee that compressed air quality is consistently performing to standard. Compressed air quality monitoring is especially important in sensitive industries like food and beverage and medical device manufacturing. Monitoring devices should be used at various points of the compressed air system on a regular, ongoing basis as compressed air quality can change due to system upsets caused by changes in ambient air, equipment failure or other reasons. Regular monitoring of compressed air quality prevents contamination and ensures the production of high-quality products in any industry.

For more information on meeting ISO Standard 8573-1:2010 for your industry, please contact a JHFOSTER expert.