Robotic Assembly Lines Maximize ROI for SMEs

U.S. International Trade Commission statistics state that small and medium-sized enterprises (SMEs) are 60% less efficient than larger manufacturers. One of the reasons is that smaller manufacturers are less likely to embrace automation. According to an article in AdvancedManufacturing.org, SMEs often lack the resources needed to implement newer technologies that would help encourage efficiency and cost effectiveness in their manufacturing operations and allow them to remain viable in an increasingly challenging business climate. However, the article explains that investment in current Industry 5.0 technologies, including automation, can help U.S. SMEs remain competitive and innovative.

Fortunately, as the robotics industry continues to introduce lower-priced, more flexible collaborative robots, SMEs are now in a better position to take advantage of the benefits of automation via the use of assembly robotics technologies without the risks typically associated with traditional industrial robots that demand large upfront investments and permanent changes to infrastructure.

As a matter of fact, many of today’s assembly line robots and collaborative robots (cobots) are suitable for smaller production facilities as cobots are lower priced, user friendly, able to work alongside human employees and offer maximized ROI.

Traditional Automated Assembly Line Challenges for SMEs

Initially, there were a lot of obstacles for smaller manufacturers interested in installing automated assembly lines, including:

- Smaller range of products that don’t support the costs associated with traditional industrial robots and infrastructure changes.

- Diversified and seasonal products, which require too much flexibility for traditional, inflexible automated assembly lines.

- Inadequate in-house expertise to program, operate and maintain complex automation and robotics.

- A lack of financial resources to deploy traditional industrial robots that require permanent changes to facility infrastructure and significant training.

The Difference Between Traditional and Modern Assembly Line Robots

While traditional robotic assembly lines were typically permanent installations that were programmed to perform one job, such as assembling the same automobile or aerospace component, modern automated assembly lines involve the use of collaborative robots specially designed and outfitted for assembly operations.

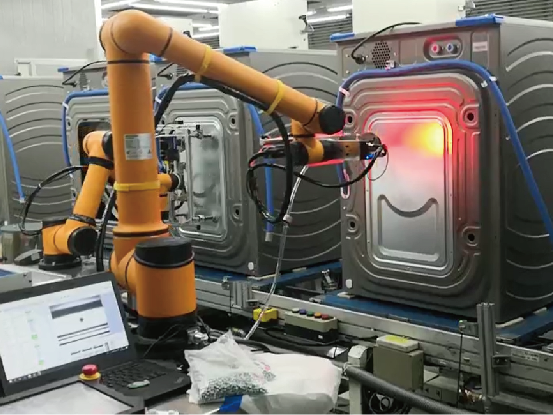

Collaborative assembly line robots can be programmed to work alongside human workers to perform repetitive tasks on production lines. They are designed to accurately grasp, move and manipulate parts and components to precisely assemble products.

Developed to be easy to install, program and operate, assembly line robots and cobots can be reprogrammed and relocated based upon production needs. In addition, an assembly line robot arm can be equipped with different end of arm tools, such as screwdrivers or grippers, so that they may perform different tasks.

Today’s assembly line robots and cobots can perform tasks including:

- Fitting parts together with high levels of precision and accuracy

- Applying adhesives and sealants

- Securing components by installing screws, bolts or rivets

- Inspecting assemblies to enhance quality control.

Exploring the Advantages of Modern Assembly Line Robots for SMEs

While it was difficult to justify the cost of traditional industrial robots for small and medium-sized manufacturing enterprises, today’s assembly line robots, especially assembly cobots, are more affordable, flexible and user friendly, opening the door for SMEs who want to deploy modern technologies in an effort to remain competitive.

Here’s just a few of the benefits SMEs may find when they install assembly robotics:

| Maximized efficiency | Assembly line robots and cobots can work continuously at high speeds without taking breaks or becoming fatigued, which will greatly enhance speed and throughput of an assembly line. |

| Improved quality | Because assembly robotics are programmed to complete a specific task the same way every time, they provide great levels of accuracy and repeatability, which means that each part will be assembled to specification with no variations, significantly increasing product quality and consistency. Assembly line robots and cobots equipped with machine vision can also be used to inspect assembled products and will provide higher levels of quality control than manual laborers who do not detect defects as fast or as well due to limitations of the human eye. |

| Minimized costs | Because assembly line robots and cobots are more accurate, there will be fewer products that do not meet specifications, which reduces material waste. In addition, there will be less re-work, which minimizes wasted labor and helps increase efficiency. |

| Enhanced safety | Assembly line robots and cobots can be deployed to perform hazardous and physically demanding tasks that can cause injuries in human workers. Additionally, collaborative robots offer built-in safety precautions such as sensors that prevent collisions with human workers and programming that slows down robotic motion when humans are in close proximity. Both factors result in an improved safety record. |

| Offset labor shortages | Like all manufacturers, small- and medium-sized enterprises have difficulty finding and retaining skilled workers, especially for repetitive assembly tasks. Using robotic assembly line technologies can help offset labor shortages and allow SMEs to put their current employees on more complex, value-added and satisfying tasks, helping increase employee retention rates. |

| Increased competitiveness | By performing assembly tasks with more efficiency, higher levels of quality and lower costs, small- and medium-sized manufacturers can consistently produce higher volumes of better-quality products in less time, allowing them to get products to market faster and increase profits. |

| Maximize ROI | By increasing productivity, quality and sales and lowering costs, many SMEs find that the return on investment for the installation of an assembly line robot or cobot is about two years. |

As automated assembly line technology, including assembly line robots and cobots, continues to advance, small- and medium-sized businesses can take advantage of the lower up-front costs, higher levels of flexibility and user-friendly programming and operation. Deploying modern assembly robotics and collaborative robots can maximize ROI by increasing efficiency and throughput, enhancing quality and reducing costs, allowing SMEs to remain viable in today’s highly competitive landscape. For information on how robotic assembly line technologies can give your small- or medium-sized manufacturing business a much-needed boost, please contact JHFOSTER today.