Human Machine Collaboration Aids Manufacturing for Medical Devices

Human Machine Collaboration Aids Manufacturing Current automation trends suggest that automation will not replace humans, instead there will be more human machine collaboration as it helps drive efficiency and quality in operations. Medical device manufacturing is one sector where this type of manufacturing collaboration between human employees and automated manufacturing systems can yield enormous benefits.

Human Machine Collaboration Explained

Simply put, human machine collaboration is the integration of human workers and automated machine capabilities and is employed in an effort to maximize manufacturing efficiency, productivity and quality. It involves the use of automated manufacturing systems, such as collaborative robots, machine vision and embedded technologies, including sensors, controllers and software that collect, process and analyze data in real time to enable precise control, which encourages greater efficiency and productivity and more consistent quality.

Collaborative robots, or cobots, are often the automation technology of choice in human machine collaboration because, unlike traditional industrial robots, cobots are specifically designed with safety features that may allow them to work alongside human laborers without barriers. Cobots typically perform repetitive tasks at higher speeds and with greater precision than their human counterparts.

However, by nature, human machine collaboration does not eliminate human employees, but rather, it allows human workers to perform more complex, problem-solving tasks, while cobots tackle the mundane, repetitive or dangerous tasks, forming a collaboration.

The Advantages of Human Machine Collaboration

By leveraging the inherent strengths of humans and machines, this type of manufacturing collaboration has the potential to provide unsurpassed levels of productivity, efficiency and quality for manufacturers.

Human machine collaboration provides several distinct advantages for all manufacturers, including:

- Increased Efficiency: The high speeds associated with automated manufacturing systems, including cobots, help increase efficiency and productivity by performing simple, repetitive tasks faster than is humanly possible. This boosts productivity by managing tasks faster and by eliminating the bottlenecks that occur when human employees, performing the same jobs, become fatigued, take breaks or change shifts. Meanwhile, human workers can use their complex thinking capabilities to ensure that quality standards are being upheld and manage any issues that could reduce productivity.

- Better Decision Making: Because modern automated manufacturing systems typically include smart, embedded technologies that supply data to operators, human employees can now use their complex intelligence, problem-solving capabilities and creative-thinking skills to make informed decisions about the process, maintenance issues, equipment availability or supply chain problems that may impact production schedules. This type of manufacturing collaboration allows human workers to redirect automated manufacturing systems to ensure more efficient use of equipment, correct process upsets, request maintenance workorders and make other decisions that optimize the process and grant higher levels of efficiency.

- Enhanced Quality: Collaborative robots excel at performing tasks with high levels of efficiency and precision, which means that products will be assembled, handled, packaged, etc. in the same manner every time. This encourages enhanced product quality as it helps eliminate human error and variations between the performance of each human operator. Not only are products more consistent, but scrap and waste are also minimized thanks to human machine collaboration. Human workers can oversee the process to ensure that quality standards meet specifications and make changes to the process or cobot programming when necessary.

Human Machine Collaboration Bolsters Manufacturing of Medical Devices

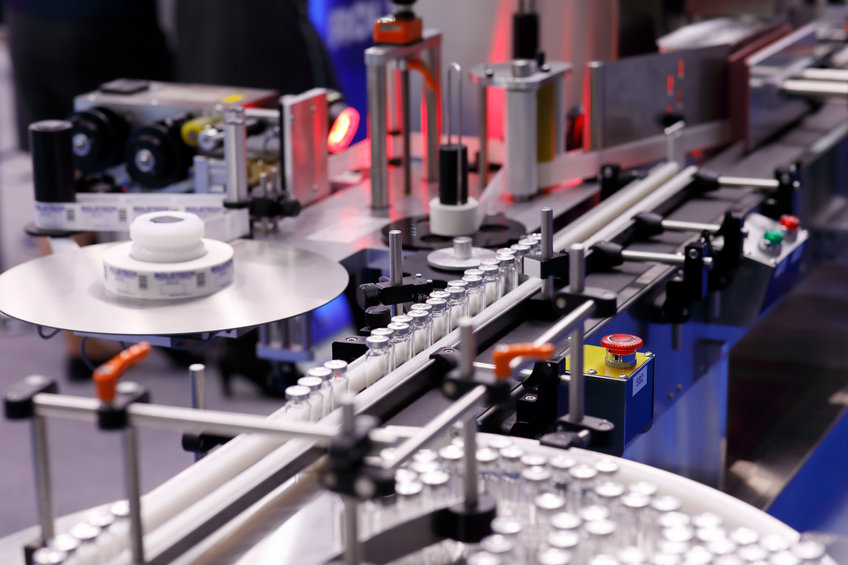

While the advantages of human machine collaboration can support any manufacturer, medical device manufacturers may find this automation trend to be especially advantageous. When it comes to the manufacturing of medical devices, which include everything from dental instruments to pacemakers to prefilled syringes to ventilators, every item must be made to exacting quality standards with precise specifications in a consistent manner to meet tight U.S. Food and Drug Administration (FDA) requirements.

Manufacturing of medical devices must meet the guidelines set forth by the FDA’s Quality System Regulation, which demands that every step in the manufacturing process is sterile, precise and consistent so that the produced devices are of the highest quality and safe for use when treating patients.

By allowing cobots to manage tasks, such as assembly, kitting, machine tending and packaging, it helps maintain accuracy and consistency under more sterile conditions, while human workers use their problem-solving skills to detect and correct any issues within the production process, ensuring that quality specifications are met, efficiency and productivity are optimized and waste and scrap are minimized.

Many medical device manufacturing tasks can benefit from this type of human machine collaboration, including:

| Machine tending | Machine tending involves the loading of raw materials into automated equipment, starting the process, unloading finished parts or products and then restarting the process. Cobots may be used to load glass vials into equipment for filling, load and unload an injection molding machine or finish needles or other sharp objects. This encourages precision, as well as consistency, safety, more sanitary production and higher levels of productivity. In a human machine collaboration scenario, human employees are kept safe from sharp objects, high temperatures and other risks, while still overseeing the process to ensure quality and consistency and manage any production issues, such as raw material/supply chain shortages or maintenance needs that arise. |

| Assembly | Assembly tasks include the precise arrangement of parts or components to create a finished product. In the manufacturing of medical devices, this must be done in a sterile, precise and consistent manner to meet FDA regulations. Cobots can work at high speeds, yet maintain the necessary levels of precision, accuracy and consistency, while also allowing more sterile conditions. In a human machine collaboration, human employees would oversee the process to ensure that finished products meet quality standards and troubleshoot any issues. |

| Inspection | As medical devices must meet strict quality standards and be made to exact specifications, it is essential that quality inspections are as accurate as possible. Cobots enhanced with machine vision and data analytics can perform exacting inspections and remove any flawed products from the line with greater levels of speed and accuracy than human employees. Meanwhile, a human machine collaboration would allow human workers to be notified when products are off spec and make informed decisions about correcting the process, minimizing scrap and ensuring that faulty or defective products are not distributed to the healthcare industry, preventing costly product recalls and associated fines. |

Human machine collaboration is advantageous when manufacturing medical devices as it provides the high levels of efficiency, sterility, precision and consistency that are required to meet FDA regulations for the production of medical devices. To learn more about how this automation trend can benefit your medical device manufacturing operation, please contact JHFOSTER today.