Category: Filters

How to Tell When Your Compressed Air System Needs New Filters

Using clean dry air is beneficial for compressed air systems in many ways. It will reduce wear and tear and maintenance required for pneumatic tools, machines, and devices used in the manufacturing environment and help maintain product quality and consistency. You can reduce machine downtime by having the proper filtration system in place while also […]

Optimizing Your Air Compression System Reduces Costs

Operating an air compression system consumes a significant amount of energy, so any improvements in efficiency will result in a better bottom line. For this reason, it is beneficial to evaluate and maintain your air system on a regular basis. In addition to ensuring that your air compression system uses less energy, regular compressed air […]

Using ISO 8573-1:2010 to Ensure Compressed Air Purity Levels

Often called “the fourth utility,” compressed air systems are used throughout the manufacturing industry and serve many functions within a facility. They drive pneumatic equipment used on items such as conveyors that move product from place to place; run tools, machines and other equipment essential to production and power packaging systems that keep finished product […]

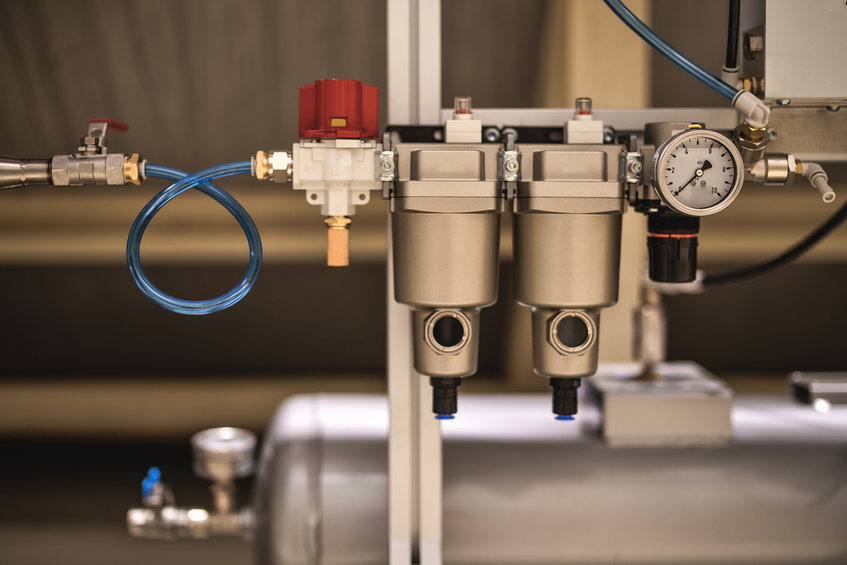

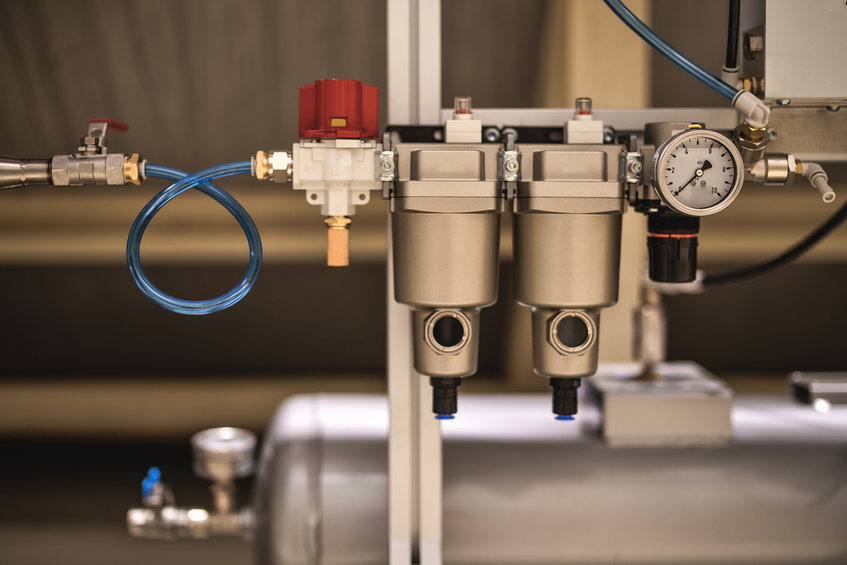

What Are the Components of a Compressed Air System?

When you first think of a compressed air system, you likely think of an air compressor first. However, there are many different components within a compressed air system that can make your applications more efficient and reliable. It’s not only important to select the right air compressor but to select the right parts and accessories […]

When Do Air Compressors Need Filters?

Seventy percent of all manufacturers use some type of compressed air system. Air compressors produce tighter, and more pressurized air to generate a steady stream of airflow. This airflow is then used to power a variety of tools, assembly lines, and pneumatic equipment. Compressed air is crucial to many industrial and manufacturing processes. If contaminated, […]

How to Remove Contaminants in Compressed Air

Today, virtually all industrial chemical processes use or interact with compressed air systems. Air compression is required in most processes, whether to add texture to products, dry sterilized equipment, divert items and ingredients along the assembly line, or perform a whole range of other tasks. Throughout all these processes that use compressed air systems, contamination […]

How Contaminants In Compressed Air Can Affect Processes

Contaminants can be introduced to your compressed air system through many mediums. Liquids like water and oil, solid particles, and vapor can cause contamination and affect production processes if precautions aren’t taken. Why is contamination such a concern? Contaminants can wreak havoc on not only your compressed air system and parts, but they can endanger […]

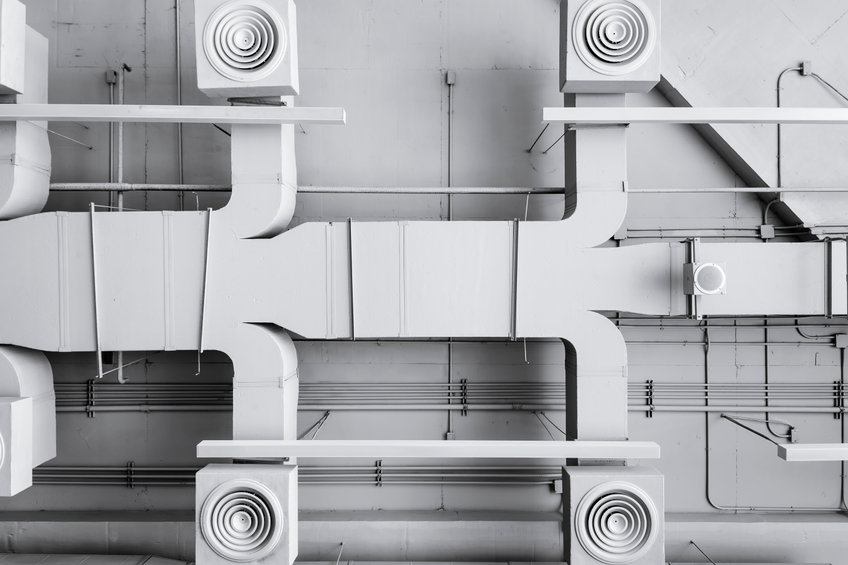

Basic Components of Compressed Air Systems

Compressed air is widely used in various industries due to its availability and ease of use. It is often known as the fourth utility, following electricity, natural gas, and water. But did you know that the idea of using compressed air to transmit energy began as early as the 1800s? During this period, metal manufacturing […]

What are Particulate Filters for Air Compressors?

Mechanics recommend that you change the air filter on your vehicle so that its heating and cooling system continues to work effectively. HVAC service providers echo a similar sentiment when it comes to your home or office’s heating and cooling equipment. But there are various industrial appliances that require similar upkeep in order to continue […]

The Different Levels of Air Purity and the Processes that Require Them

According to the World Health Organization, poor air quality kills an estimated seven million people globally each year. If you needed a single statistic to help underline why air purity is critically important, let it be that one. Poor air quality is everywhere – from smoke or carbon monoxide in homes to the smog that […]