Boost Machine Efficiency with Pneumatic Valves

Pneumatic systems play an essential role in today’s manufacturing industry. Pneumatically driven equipment includes critical process equipment, automated systems, manufacturing machinery, packaging and bottling lines, material handling machines and conveyors, industrial robots, machine tools and more.

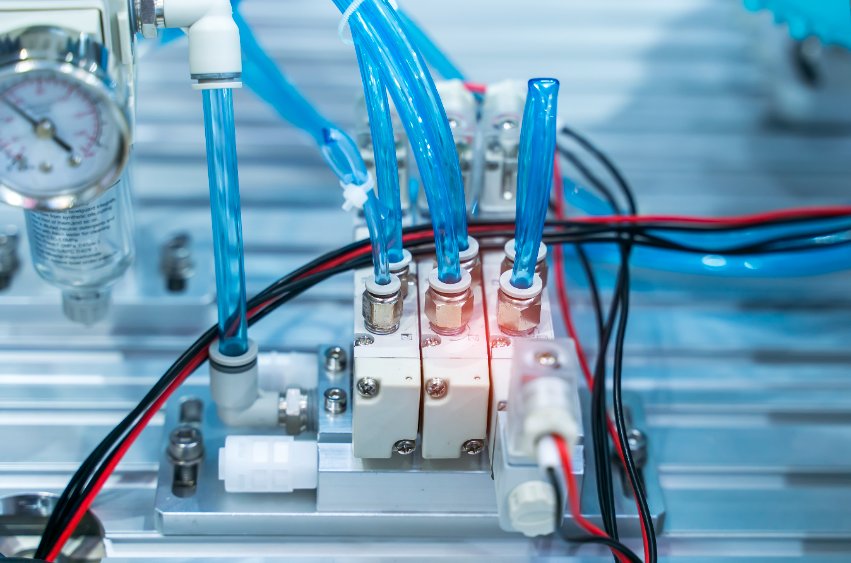

The pneumatic systems that drive industrial equipment operate using air pressure, but for pneumatic systems to be effective, there must be a way to control how much air can pass through and in which direction to send it. This is where pneumatic valves come in as they regulate the rate, flow, direction and pressure of compressed air, enabling precisely controlled motion and elevating the efficiency of automated machinery.

This blog will explore Aventics pneumatic valve technologies and the ways in which pneumatic valves help boost the efficiency, safety and reliability of industrial machinery across various industries.

What is a Pneumatic Valve?

Also known as a pneumatic valve or a directional control valve, pneumatic valves keep pressure constant and switch airflow in pneumatic systems, providing efficient and effective control in pneumatically operated systems, automation, machinery and equipment.

Based on the type, pneumatic valves can perform a number of functions such as switching a single airflow path on and off, providing precise proportional control of pressure and flow, directing airflow and serving as a safety component by releasing pressure or discontinuing airflow in a hazardous situation.

Because there are so many different ways that pneumatic valves can be applied in a pneumatic system, there are several different kinds of pneumatic valves available, including:

| Two-, three- and four-way directional control valves | These pneumatic valves are classified based on the number of ports, with each port serving a purpose, such as supply, exhaust or output to an actuator, which is the component that enables motion in the equipment. |

| Normally Open- or closed-resting state valves | Pneumatic valves with open and closed functionality regulate the airflow in the system by permitting or shutting off airflow to the actuators in industrial equipment. |

| Spring-offset pneumatic valves | Certain types of pneumatic valves have a spring mechanism that opens or closes the ports, allowing or discontinuing airflow. |

| Solenoid valves | This type of pneumatic valve is commonly used in manufacturing environments and responds to electric signals by opening and closing to regulate airflow. |

How Pneumatic Valves Boost Machine Efficiency

The tight and precise control of pressure, airflow rate and direction offered by pneumatic valves helps to accurately control the motion or movement of the equipment or process so that it operates smoothly and performs effectively and efficiently.

While the main function of pneumatic valves is to control the flow of air in pneumatic systems and equipment, by doing so, they prevent wasted energy by allowing only the required amount of air, at the specified pressure, to be sent to the machinery, boosting the energy efficiency of the machine.

Further, because pneumatic valves are not complex and those provided by trusted manufacturers such as Emerson Aventics are robust enough to operate in harsh industrial conditions, they lend reliability to pneumatically operated equipment, reducing maintenance needs and increasing availability of manufacturing and processing equipment, automated systems and industrial robots to keep production moving.

Applications for Aventics Pneumatic Valves

Because pneumatic valves, especially Aventics pneumatic valves, are so reliable in operation, they are used to ensure safety, regulate pressure and flow, control and direct airflow and turn airflow on and off in a variety of applications across a broad range of industries.

Some applications for Aventics pneumatic valves include:

- Processing Equipment: Processing equipment in the chemical, food and other industries relies on pneumatic systems. Pneumatic valves ensure smooth, accurate and precise control of airflow and pressure, keeping the process within operating parameters so the finished product meets quality specifications.

- Automation Systems and Equipment: In pneumatically driven automation, pneumatic valves accurately control the pressure, rate and airflow to provide tight control, optimizing the efficiency and performance of all types of automated equipment and robotics.

- Bottling Equipment: Bottling lines rely on pneumatics for every part of the bottling process. Pneumatic valves provide efficiency, reliability, accuracy and consistency in these high-speed operations, enhancing productivity and efficiency.

- Manufacturing Machinery: The general manufacturing industry is highly reliant upon pneumatic equipment, so here pneumatic valves help bring flexibility, control, precision and reliability to all types of manufacturing equipment, ensuring energy efficiency and optimal performance of assembly lines, material handling and conveying equipment, presses, painting equipment, robotics and other machinery commonly found on the manufacturing floor.

- Packaging Machinery: Pneumatic valves help bring precision control and reliability to all types of equipment in the packaging industry, such as case packers, form/fill/seal equipment, PET blowing and bottle manufacturing and more to boost the efficiency, consistency, productivity and throughput of high-speed packaging operations.

Aventics pneumatic valves integrate with hundreds of processes, industrial and automation applications to ensure high-performance, effective operation and energy efficiency. For more information on the many types of pneumatic valves available from Emerson Aventics and how they can help optimize the performance and boost the efficiency, safety and reliability of pneumatic machinery, process equipment and automation in your facility or industry, please contact JHFOSTER, a Tavoron company.