Month: February 2024

Innovative Injection Molding for Medical Devices Supports Patient Care

Providing the best patient care is the number one priority in the healthcare industry and injection molding processes are constantly evolving to supply healthcare providers with high-quality medical devices that meet or exceed their patient care standards, while also allowing medical device manufacturers to remain cost efficient and relevant in a highly competitive industry. The […]

Automated Verification Systems Boost Quality, Efficiency and the Bottom Line

In an increasingly competitive market, quality control is a critical aspect for manufacturers and packagers who want to keep their customers satisfied so they continue to return to their brand or business. To ensure quality control and maintain the high standards that encourage brand loyalty, manufacturers and packagers should consider the addition of a next-generation […]

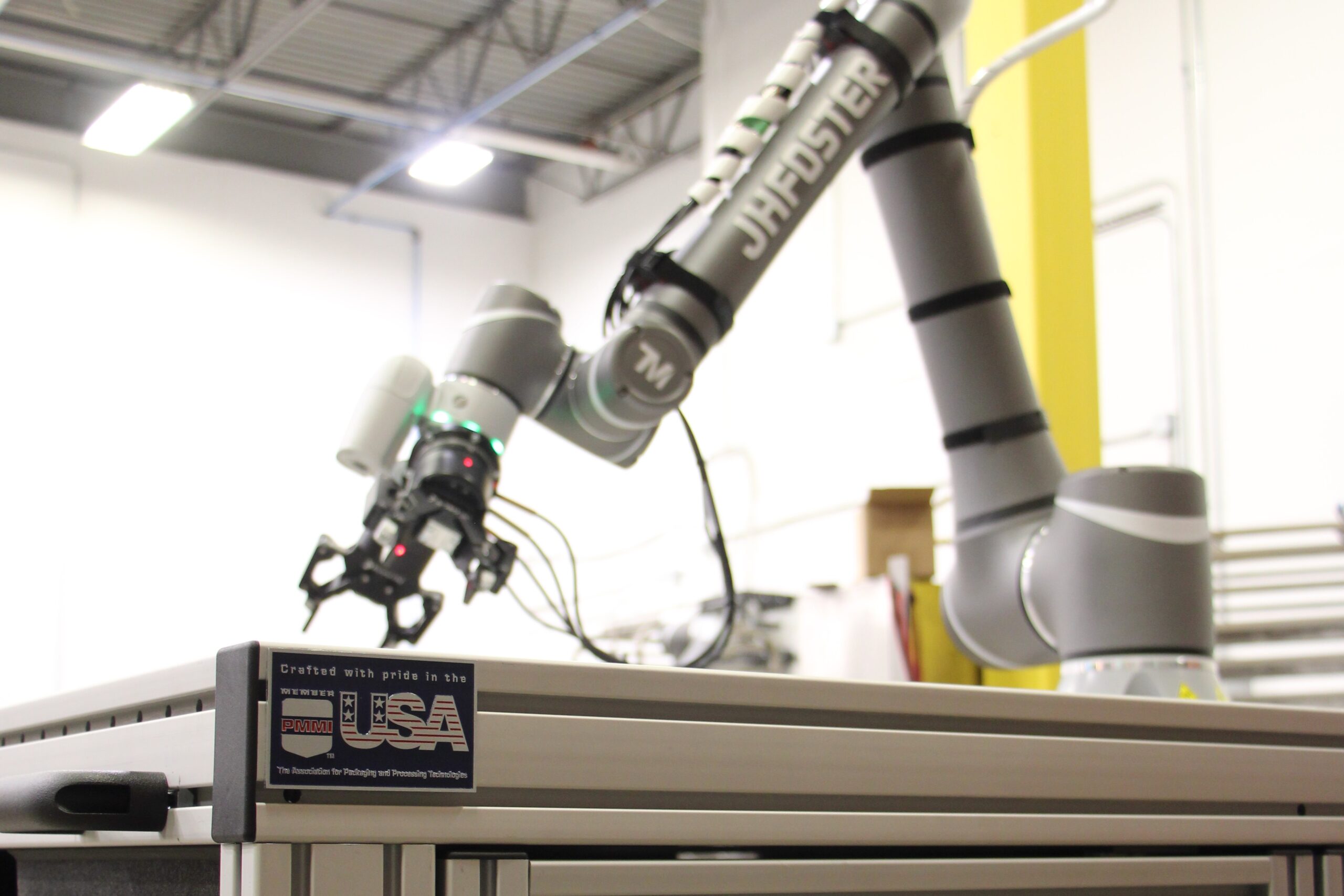

Expert Programming Services Maximize Cobot Efficiency

Cobots (collaborative robots) are an alternative to industrial robots that can be made to work safely alongside human workers with minimal guarding. Manufacturers who are unfamiliar with the technology or lack programming experience should consider working with an expert programmer to ensure optimal performance and safety. Cobots: 101 Collaborative robots are designed to be able […]

Future-Proofing Manufacturing Operations with Automation

Manufacturers are faced with the constant struggle to increase efficiency, retain skilled labor and cut costs, while simultaneously planning for the future of the business. The good news is that adopting automation technologies now can help industrial facilities manage today and ensure success tomorrow by overcoming current and upcoming challenges. Future-proofing, by definition, is the […]

The Importance of Expert Service and Repair for Air Compressors

An air compressor is one of the hardest working pieces of equipment in most industrial facilities as it powers essential tools and machinery. So, when an air compressor is not running in optimal condition or – worse – at all, it can result in excessive costs for a manufacturer, including higher energy bills, shorter equipment […]

8 Ways Custom Workstations Support Lean Initiatives

Previously just a thoughtless assortment of tables on the plant floor, workstations are now taking on a strategic role in industrial facilities as more studies find that well-designed, purpose-driven workstations can increase efficiency and support lean initiatives that aim to curtail waste in inventory, motion and labor hours. As a matter of fact, research has […]

The Importance of Automated Inspection Systems in Packaging Verification

Damaged or incorrect packaging results in unhappy customers and negative brand recognition in the least detrimental situations and product recalls and regulatory fines in the worst, making packaging verification extremely important in most industries, but especially critical in others, such as food and medical manufacturing, where damaged packaging or incorrect labeling can interfere with human […]

5 Benefits of Real-Time Analytics and Smart Manufacturing

When a manufacturing facility is running smoothly at full capacity, it can produce thousands of products per day…until a critical piece of equipment fails and production comes to a screeching halt, costing thousands of dollars per hour in downtime, lost productivity and repairs. No manufacturer wants to experience this scenario, but thanks to real-time analytics […]

Pick and Place Robot Innovations Deliver for Food Manufacturers

The worldwide need for food has never been greater and, as a result, the food processing industry is struggling to meet the demand. For this reason, smart food manufacturers are turning to automated solutions to boost efficiency, cut costs and ensure quality while also increasing throughput. Because pick and place robots are adept at managing […]