Expert Programming Services Maximize Cobot Efficiency

Cobots (collaborative robots) are an alternative to industrial robots that can be made to work safely alongside human workers with minimal guarding. Manufacturers who are unfamiliar with the technology or lack programming experience should consider working with an expert programmer to ensure optimal performance and safety.

Cobots: 101

Collaborative robots are designed to be able to work safely in close proximity to human workers in industrial settings. They are equipped with advanced navigation, force-feedback sensors, and software algorithms to automatically stop themselves if they collide with anything unexpectedly. Some cobots are easier to program than their industrial robot counterparts.

This helps reduce the cost of the investment and provides the flexibility to adapt to different tasks as the production process evolves. Collaborative robots are intended to boost the throughput of industrial processes by efficiently automating repetitive tasks, allowing human workers to focus on operations that require complex problem solving. Cobots can be used for machine tending, assembly, packaging, sorting, and many other dull, dirty, and/or dangerous tasks at industrial facilities.

What Cobots Bring to the Factory Floor

Increased productivity: Cobots can work faster and more efficiently than humans. They don’t get tired, they don’t get sick, and they can work 24-7 to eliminate bottlenecks and further improve throughput.

Improved accuracy and reliability: Cobots do exactly what you tell them to do, the same way, every time. Their results will be highly accurate and repeatable, unlike manual laborers who make mistakes.

A safer workplace: Cobots can be used for dull, dirty, and/or dangerous tasks, which protects human operators from injuries and fatigue and frees them to perform more appropriate tasks

Are Cobots Really Easier to Program?

Robots in general are becoming easier to program. Programming a collaborative robot can vary depending on the type of cobot, the manufacturer, and the application. Anyone undertaking the programming will have to understand the following:

The Application | Granularly define the cobot’s tasks, its interactions with human operators, its interactions with other machinery in the process, its safety systems, its recovery procedures, its environment, etc. |

The User Interface and Programming Language | Some cobots can be programmed using a graphical user interface, in which users can drag and drop commands and sequential actions to build programs with relative ease. Regardless of the interface, the programmer will need to intimately understand the programming language to create complex or customized programs. |

The Safety Requirements | Cobots themselves are designed to be able to work among humans. They can reactively detect collisions and stop themselves, but they cannot predict collisions without sensors. These sensors need to be selected, safely integrated, configured, and calibrated for the specific environment and application. |

The Work Cell | Despite the safety features of cobots, the machinery they interact with often demands guarding anyway, so it is common to see cobots installed within work cells. The work cell must be designed, built, and tested to accommodate the application. |

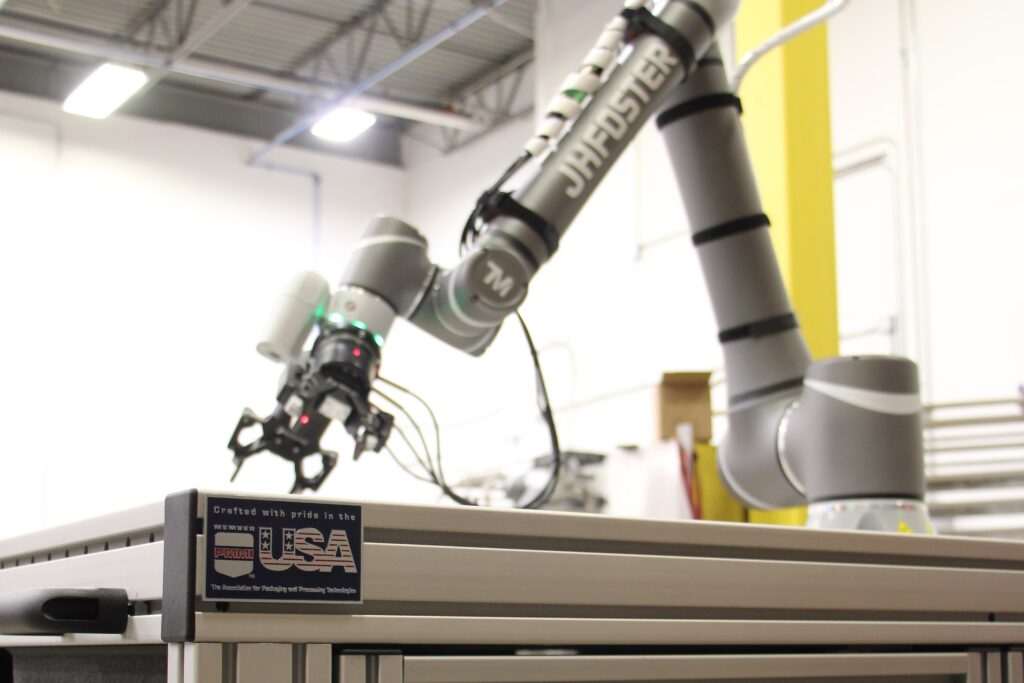

End of Arm Tooling | Cobots and robots require standard or customized end-of-arm-tooling to pick up and handle the necessary objects for the application, such as pallets, oily parts, bagged products, boxes, fasteners, etc. |

Teaching through Demonstration | The approximate motions can be taught to the cobot by physically moving the joints through the sequence of actions to teach the waypoints. Afterward, fine adjustments can be made with the controller. |

Testing the Application | Once programming and integration is complete, it is essential to thoroughly test everything to ensure accurate, consistent, and safe performance of the system. It is likely that adjustments or refinements will be required to achieve the most efficient and effective system performance. |

Is an Expert Programmer Necessary?

Cobot programming is typically less complex than programming a traditional industrial robot, but the complexity of the application and any risks to human operators is what really drives the difficulty. It is always beneficial to use an expert programmer experienced with applications in your industry.

JHFOSTER’s expert programming and integration services can ensure optimal performance and safety when automating your manufacturing process, meeting or exceeding desired cycle times, safety expectations, and other criteria. JHFOSTER also designs custom end-of-arm-tooling. Contact JHFOSTER today with any questions about cobot programming or to inquire about expert programming services.