Month: December 2023

Best Practices for an Efficient Compressed Air Distribution System

If your facility has been experiencing pressure drops in the compressed air supply and higher than normal electric bills, the culprit may be the compressed air piping system. In fact, issues within the distribution system can greatly influence system performance and efficiency. Applying best practices to the compressed air piping system will ensure that sufficient […]

5 Conveyor Design Considerations for Maximum Efficiency

Conveyors serve as the circulatory system of most industrial facilities as their function is to move product through the facility for processing. In the same way that circulatory system diseases can wreak havoc on the human body, poorly designed conveying systems can create bottlenecks and waste within the manufacturing plant or warehouse. And, just as […]

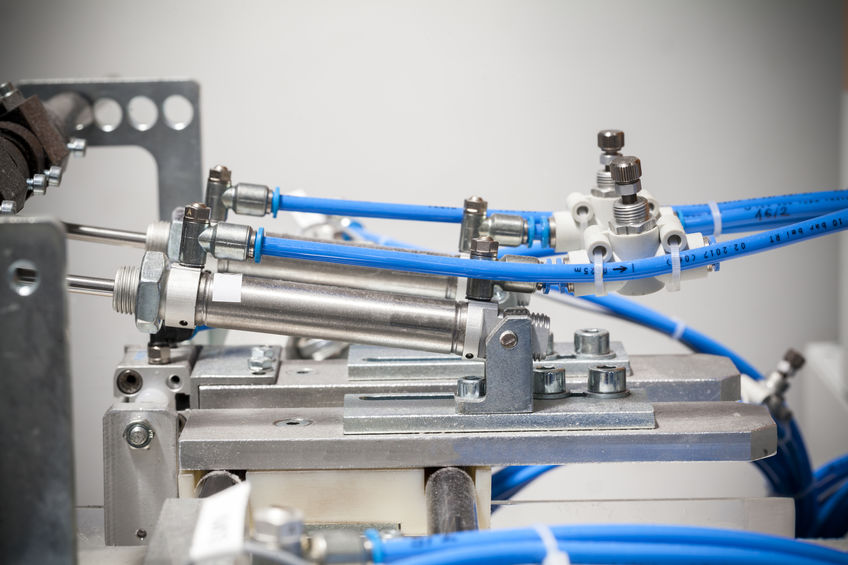

Automation in Action: 4 Real-World Applications for Pneumatic Systems

Pneumatic systems rely on compressed air, a few simple components and an arrangement of tubes or piping to bring motion and movement to machinery, equipment and tools. Their straightforward, clean and low-cost source of power makes pneumatic systems an attractive option across many sectors and, as a result, more engineers are specifying them for automation […]

Air Dryers: The Secret Weapon of the Compressed Air System

Air dryers are essential to removing moisture and humidity – byproducts of the air compression process – from the treated air. By doing so, they safeguard the compressed air system, pneumatically operated equipment and even finished products against contamination and corrosion, making air dryers the secret weapon of industrial facilities that rely on air compressors […]

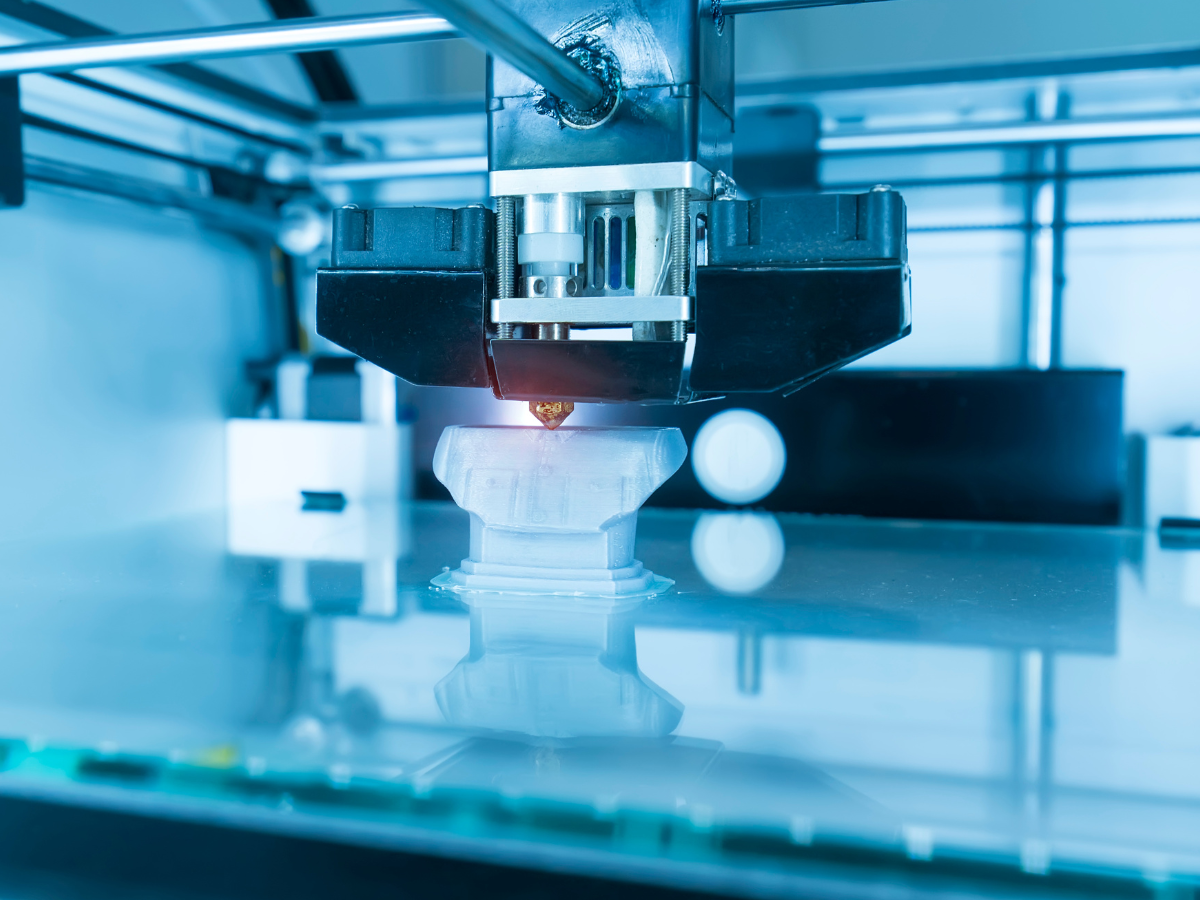

How Robotics Can Assist the 3D Printing Revolution

3D printing, also called additive manufacturing, is a method of creating an object, product or part by adding layers of material, which differs from traditional manufacturing techniques that take away material through grinding, drilling, machining or casting in a mold. More manufacturers are exploring the use of 3D printing for prototyping and small-scale production because […]

Using Manufacturing Analytics to Unlock Operational Insights

Smart sensors and devices associated with the Industrial Internet of Things (IIoT) and Industry 4.0 allow automated manufacturing equipment to communicate with specialized software and applications, providing visibility into machinery and processes. Savvy manufacturers are using this deeper understanding to unlock operational insights and make informed, real-time decisions that boost efficiency and throughput, enhance quality […]

Automation Aids Reshoring of American Manufacturing

Reshoring – the act of moving manufacturing and production away from offshore locations and back to the U.S. – is a recent business trend that a growing number of American manufacturers are considering as it can boost product quality, supply chain resiliency, speed to market and brand loyalty, while also improving local economies and sustainability […]