Why Smart Manufacturers Choose the Gardner Denver Ultima™ Compressor

In today’s competitive manufacturing environment, energy efficiency, space optimization, and operational reliability aren’t just nice to have – they’re essential. That’s why more small-to-mid-sized manufacturers are making the switch to the Gardner Denver Ultima™ U75–U160 oil-free compressor.

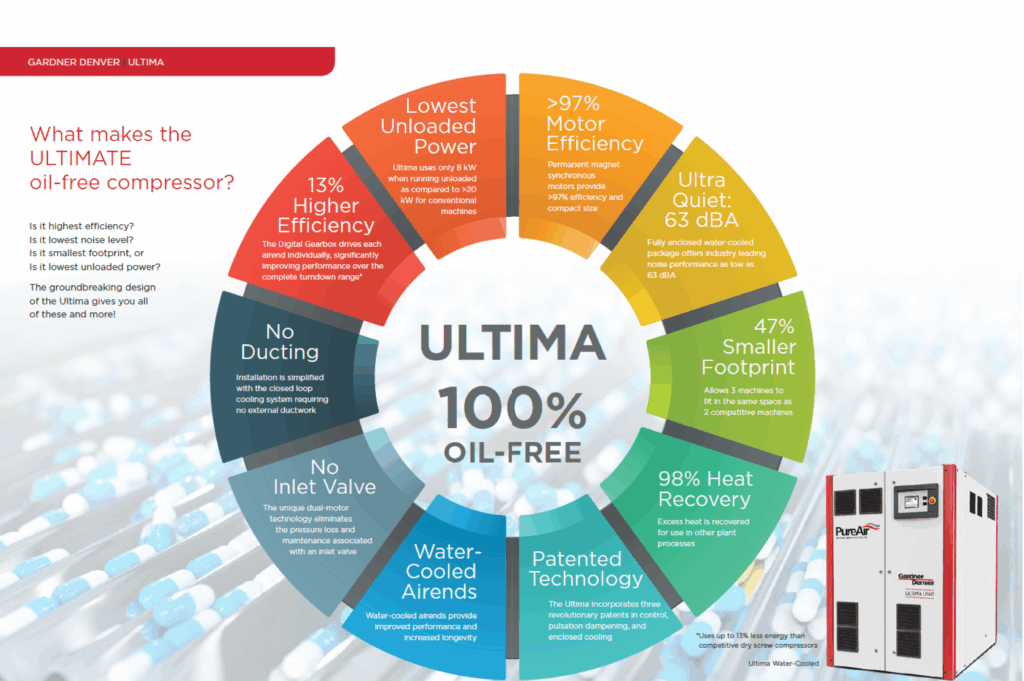

With a groundbreaking design that eliminates gearboxes, reduces idle power usage, and recovers more heat than conventional units, Ultima™ delivers superior performance in a compact, quiet, and environmentally responsible package.

Here are the six key reasons why smart plant managers and engineers are choosing Ultima™.

1. Power and Performance That Sets the Standard

Ultima isn’t just efficient; it’s engineered for maximum output across the full operating range. With two permanent magnet motors (>97% efficiency) driving the low and high-pressure airends independently, the compressor precisely adjusts to demand while eliminating traditional mechanical losses.

And because there’s no gearbox, the power goes straight where it’s needed-delivering best-in-class performance at both full and partial load.

2. Lower Total Cost of Ownership

Ultima was designed with operating costs in mind:

- Just 8 kW power draw at idle (vs. 15–25 kW in traditional models)

- No oil, no filters, no mess = lower maintenance

- Heat recovery system provides free hot water or HVAC assistance

- Fewer moving parts mean reduced wear and less downtime

Over time, these savings add up dramatically cutting your cost per CFM and improving ROI.

3. Compact Footprint Saves Floor Space

At just 86” x 55” x 79”, Ultima has up to 47% smaller footprint than comparable compressors. That’s a big deal for smaller manufacturers or facilities expanding production without expanding the building.

No ducting required (for water-cooled versions), no extra sound enclosures, and no oil containment systems equals fast, simple installation.

4. Quiet Operation That Won’t Disrupt Production

Running at just 63–70 dBA, Ultima is quiet enough to place near work areas – making it ideal for space-constrained shops, labs, or food production lines.

The sealed enclosure and water-cooled design eliminate noisy fans and airflow, offering a cleaner, quieter, and more comfortable workspace for your team.

5. Reliability You Can Count On

Ultima is packed with smart, low-maintenance design choices:

- No gearbox to maintain or replace

- No intake regulator — just a simple blow-off valve

- Fully enclosed and water-cooled: motors, inverters, airends, coolers

- ISO 8573-1 Class 0: completely oil-free air for the most sensitive applications

It’s a compressor built to run longer, cleaner, and with less intervention.

6. Environmentally Responsible by Design

Ultima’s integrated heat recovery system captures up to 98% of the heat generated, delivering outlet water up to 194°F for reuse in processes or HVAC systems.

Compared to typical compressors, Ultima provides up to 13% more recoverable heat, helping manufacturers:

- Reduce carbon footprint

- Lower HVAC loads

- Cut utility bills

- Move closer to sustainability goals

Built for Modern Manufacturing

If your plant is facing rising energy costs, tightening space, or higher performance demands — Gardner Denver Ultima™ offers a smarter, more sustainable solution. It’s the kind of technology that pays for itself quickly and supports your long-term operational goals.