Who Makes the Best Industrial Robot?

That depends on your application and needs.

Industrial robots are suitable for many tasks. From injection molding to packaging, the repetitive tasks within your business could be easily automated. The possibilities are nearly endless. However, if you’ve been researching different industrial robot manufacturers, you may be struggling to identify which one is right for you. While there are many robots available on the market, it can be helpful to first understand what the different types of industrial robots are. This helps you understand which robot is capable of meeting your specific application needs.

So first, let’s dive into the different types of robots on the market today, and then we will explore a few of the top industrial robotic manufacturers.

The Different Types of Robots

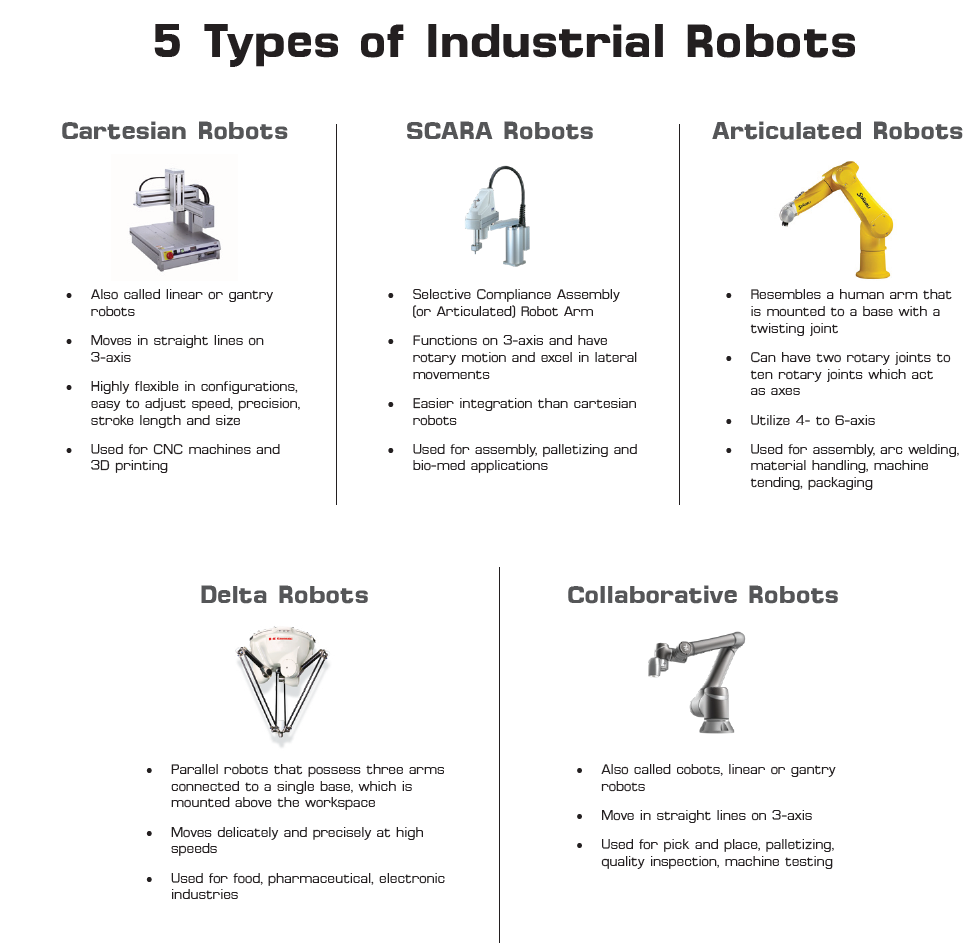

There are several different types of robots each with their own particular abilities. For an in-depth overview of the different robots available to you, check out our robotics product page. Below you can find a quick summary of each.

Cartesian robots are often used for CNC machines and 3D printing. These robots are known for their adjustable speed and precision.

Collaborative robots (also known as cobots) are well known for their exceptional flexibility for pick and place, palletizing, quality inspection, and many more tasks. Cobots are also known for their safety capabilities and often are found working alongside human coworkers.

Articulated robots can often be found in assembly, material handling, and packaging environments. Much like collaborative robots, these robots look similar to a human arm. However, they differ in their respective designs. Cobots move on three axes, while articulated robots move on four to six axes.

Scara robots are frequently used for assembly, screw driving, and other manufacturing applications. Scara robots also function on three axes, while also utilizing rotary movement.

Delta robots are most commonly used for pick and place applications and can be seen in a variety of industries such as pharmaceutical and food/beverage.

Polar robots aid in die casting, injection molding, and material handling. They utilize one linear and two rotary joints to complete tasks.

Industry-leading Robotic Manufacturers

There are many robotic manufacturers in the industry, each providing their own particular benefits. However, the best robotic manufacturers offer both flexibility and ease of use. Below are industry-leading robotic manufacturers that we believe offer the greatest benefits.

Techman Robots are a collaborative robot technology featuring built-in vision systems. This fact is very uncommon as competitors often do not offer built-in systems. Beyond this great feature, Techman Robots are also well known for their software being accessible through any laptop running Windows. Even better still, Techmans include safety features allowing robots to work alongside human co-workers in most settings. Robot stands and workstations are also available for added flexibility.

Fanuc robots are user-friendly and easy to program. Similar to Techman Robots, Fanuc collaborative robots are also deployable alongside a human workforce. Used frequently for CNC and factory automation, Fanuc robots can be found in a variety of industries and locations.

Kawasaki manufactures 6-axis robots, scara robots, and pick-and-place robots. One great example of Kawasaki’s capabilities are in technology inspection settings. Featuring high-speed along with flexibility, Kawasaki robots are fit for a wide array of environments. Many factories find that Kawasaki robots are adaptable to varying needs across their facilities.

Staubli provides SCARA robots, collaborative robots, AGVs and AMR’s. With fast, user-friendly, and collaborative designs, Staubli robots offer precision and accuracy. These robots are well-known for their food industry-friendly features and for their deployments in the automotive manufacturing setting. However, Staublis can be found performing a large variety of tasks across many industries. These robots are by far one of the most adaptable.

ABB Robotics has worked hard to create solutions that cater to a plethora of industries. With a variety of industrial robots and accessories, ABB robotics has the flexibility to assist in a range of different applications. Also, if you are looking for collaborative robots with built-in safety features, ABB can help.

Identifying the Right Robot

Now that you know about the different types of robots and top manufacturers, you are now more informed to select the right robot for your needs. Here are a few last words of wisdom. When identifying the right robot for your particular application, you should ask yourself a few questions. What speed do I need for my application? Is flexibility an important selection criteria? What payload capabilities do I require? Does my team require easy-to-use software or do we have the budget for training? By answering these questions, you will be several steps closer to minimizing your list of suitable robots.

Contact One of Our Robotic Specialists

While robots can be used to perform hazardous and repetitive jobs, choosing the right industrial robot for your application can seem like a daunting task. However, it doesn’t need to be. One of our robotic specialists would be happy to help you identify the right robot for your needs. Reach out to one of our robotic specialists for assistance.

Would you like to find out how much you could save by deploying robotic technology? Check out our Robotics Savings Calculator to determine the potential ROI your business could receive from a robot purchase in just three years.