Using Aluminum Framing to Create Automotive Assembly Line Structures

Automotive manufacturing is always evolving. As consumer demands, safety standards and government mandates continue to change, automotive assembly plants must adapt and refine their processes to remain competitive. Using modular aluminum framing systems to create customized automotive assembly line structures provides flexibility and versatility so automakers can keep pace with changing market demands.

Automotive Assembly Plant Challenges

Automotive manufacturers require high levels of efficiency, safety and quality control to meet productivity goals while keeping costs down and remaining agile enough to keep up with changes to production that are driven by consumer demands and government regulations for vehicle and worker safety.

This means that automotive assembly plants must find ways to produce cars faster and more cost effectively, without compromising safety or quality and without significant downtime.

5 Ways Using Aluminum Framing Systems Enhances Productivity

Aluminum framing systems are made from aluminum that has been extruded through a cast or die of a specific pattern to create a uniform profile that is rust and corrosion resistant. The result is T-slot aluminum profiles that can be interlocked and secured in place with fasteners, nuts or bolts to create strong, sturdy structures. No welding, priming, painting or coating is needed and the components can be arranged in unlimited designs to construct and customize anything from safety barriers to workstations to automation supports.

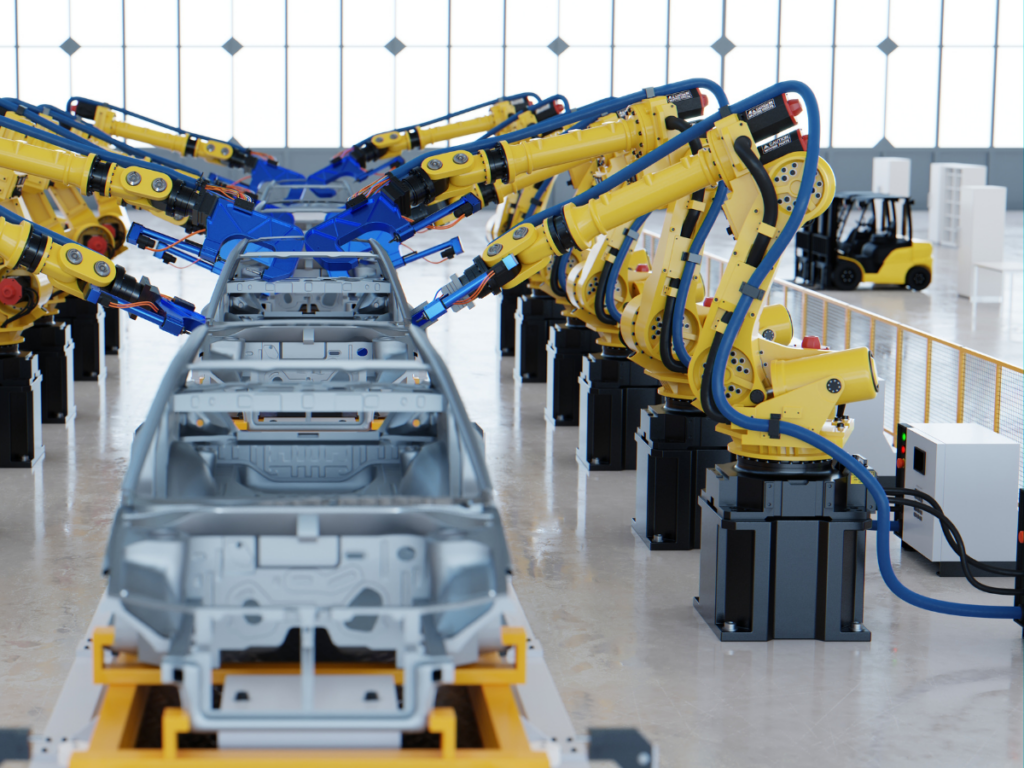

Creating customized aluminum structural framing supports for critical automotive assembly line infrastructure, such as safety guarding, mobile workstations and supports for robotics and conveying systems, allows automotive workers to complete their jobs safely and with greater levels of efficiency and flexibility than purchasing off-the-shelf units that do not support the specific tasks being performed on the automotive assembly line. This is because aluminum framing systems and components allow users to construct structures and workstations that align exactly with the environment, processes and workflows that are unique to each automotive assembly plant.

Here are five ways that aluminum framing can enhance the efficiency of automotive assembly lines:

- Less downtime: Automotive assembly plants see a lot of demanding activity and this can be tough on the infrastructure used on and around the production lines. The materials used to support robotics, conveyors and tools must be able to handle the daily rigors of automotive assembly lines. Supports made from high-quality T-slot aluminum framing and components are durable and sturdy enough to withstand the repetitive motion while maintaining tight, secure connections. This means there is less time spent repairing, reinforcing or replacing structures that aren’t strong enough to support heavy loads without bending or withstand constant vibrations without breaking. If the environment is hot and humid, aluminum framing is also rust and corrosion resistant, increasing its durability in harsh manufacturing conditions.

- Increased flexibility: Because there are constant production changes, automotive assembly plants must be agile enough to quickly and efficiently shift gears. Thanks to the use of T-slot aluminum pieces and easy-to-use connectors, aluminum framing systems can be disconnected and reconnected easily. There is no welding, priming or coating required and installation is often done using simple tools and fasteners. This means supports and workstations made from modular aluminum framing systems can be reimagined and redeployed easily and repeatedly to accommodate automotive assembly line changeovers with very little downtime and with no additional investment.

- Customized supports: With hundreds of profile shapes that range from light to heavy duty, aluminum framing, fasteners and accessories can be configured into an unlimited number of designs. Devices and components can be added or repositioned along the T-slot aluminum channels, allowing the creation of supports, structures and workstations that meet the unique needs and challenges of each automotive assembly line. The ability to erect customized solutions, such as workstations and storage racks, helps increase the efficiency of the workforce as there is a defined place for all the tools and accessories workers need to complete their job as effectively as possible, helping to enhance productivity.

- Enhanced Worker Safety: Automotive assembly lines contain a lot of fast-moving, dangerous equipment, so worker safety is a high priority. Aluminum framing systems can be used to create protective structures, such as guardrails, safety barriers and enclosures, around equipment, distancing workers from hazardous areas to reduce the risk of accidents and enhance worker safety.

- Cost Effective: The ability to quickly set up aluminum framing systems without welding, priming or painting makes them more time and cost effective than other solutions. In addition, because they can be disconnected, relocated, reconfigured and/or rearranged to suit evolving production needs, their cost effectiveness is further increased as there is no need to purchase new supports, structures and workstations each time there is a change on the automotive assembly line.

To learn more about how the efficient assembly, versatility, durability and cost effectiveness of aluminum structural framing systems can enhance the operational efficiency and safety of your automotive assembly plant, please contact JHFOSTER, a Tavoron Company.