How to Select a Pick and Place Robot

Robotic automation has become commonplace in industrial applications because it increases productivity and throughput and pick and place robots have been especially helpful in this regard. Recent innovations, including vision systems and advanced end of arm tooling, allow pick and place robots to be used in more applications than ever before – further enhancing efficiency in more operations. But specifying a pick and place robot can be an intimidating endeavor, so here we explore the different types of pick and place robots and provide insight into important selection criteria to simplify the task.

What is a Pick and Place Robot?

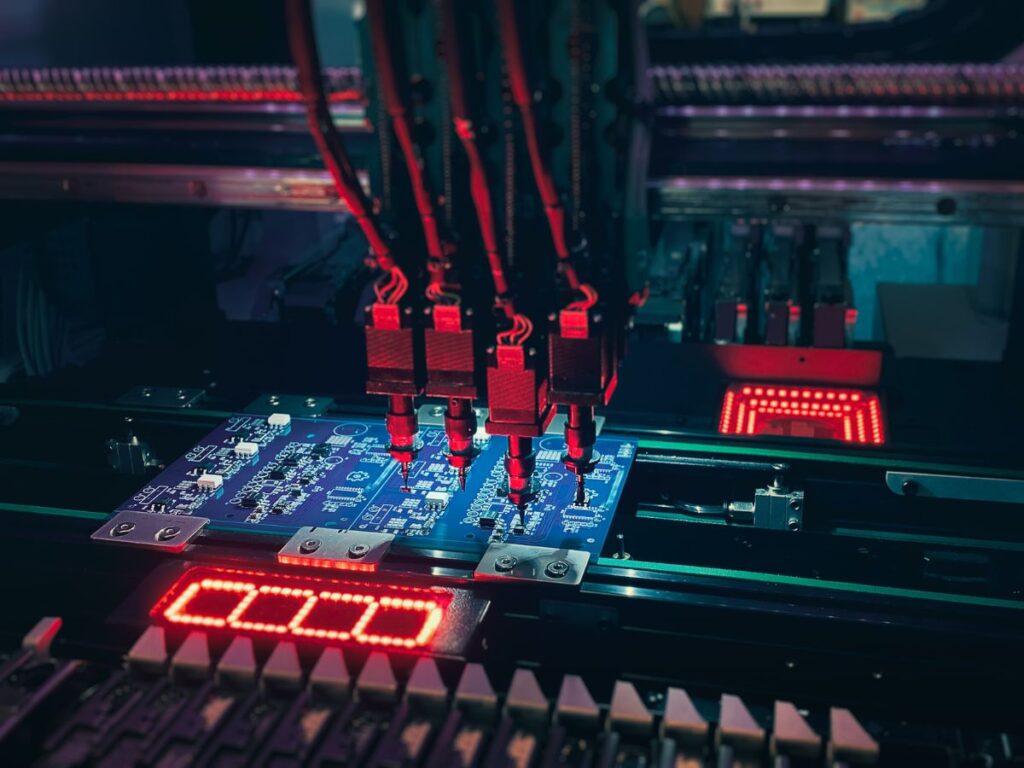

Pick and place robots are automated solutions for simple, repetitive tasks such as picking up objects from one location and moving them to another. They are often used to relieve workers of performing these often boring and efficiency draining tasks because pick and place robots can do so with higher speeds and greater accuracy while allowing employees to tackle jobs that require more complex problem-solving skills. Initially, pick and place robots were used to move heavy objects and place them on pallets or conveyor belts, but recent developments, such as more delicate and agile grippers and vision systems, allow today’s robots to pick up the smallest of objects, sort them, assemble them and even inspect them.

Before discussing the selection process for pick and place robots, it’s a good idea to determine the type of application in which it will be used, as they range from bin picking to assembly to inspection. Some examples include:

- Part Sorting: Modern pick and place robots can pick up and sort parts or objects according to size, shape and even color and place them in different bins or kits.

- Assembly: Today’s pick and place robots have the ability to select and pick up different components from multiple locations and construct them into a larger assembly. Advanced grippers allow even sensitive and delicate items to be manipulated and assembled by robots.

- Bin Picking: With or without vision systems, pick and place robots can be programmed to select parts from one or more bins and place them in another location such as a kit or conveyor belt where they will move down the line for further processing. Those equipped with vision systems can identify items based on color, shape or identifying markers from a variety of bins.

- Inspection: In inspection applications, pick and place robots can pick up parts or products as they move down the line and inspect them for defects to ensure quality. They can return the product to the line if it meets quality control requirements or reject it if it does not.

- Packaging: Here, pick and place robots can select a product from the line and place it into its intended package or they can lift finished and packed items and place them onto pallets for shipping.

Types of Pick and Place Robots

Most pick and place robots are attached to a stable base from which they can reach the required work areas, but because there are so many potential applications, there are a variety of robot types available to meet the needs of almost any operation.

Five or six-axis robotic arms are commonly used in complex pick and place applications where an expanded range of motion is required.

Delta robots, which consist of three arms mounted on a triangular base, are suitable for packaging applications and applications where they need to place items in certain assembly patterns. They also excel at high-speed pick & place applications.

Collaborative robots might be used in pick and place applications where they need to operate close to workers. Collaborative autonomous mobile robots are often employed in large warehouses to help find the most direct route, optimizing picking time.

Often used in high-volume manufacturing settings, gantry robots run along a beam that spans the width of the work area or production line, allowing them to quickly and concisely select objects from one area and place them on a production or assembly line for further processing.

With a horizontal arm and a vertical arm, SCARA robots are suitable for use in assembly operations because they swiftly and accurately select products, manipulate them and place them on the assembly line.

Capable of moving items in multiple planes using X,Y and Z coordinates, cartesian robots are used in applications that require more dexterity than is provided by 5- or 6-axis robotic arms.

Fast pick robots are ideal pick and place robots for high-speed applications as they offer cycle times of 150 cycles per minute or more.

Pick and Place Robot Selection Criteria

Once you determine which type of robot best fits the application and your budget, it is possible to narrow down the choices based on essential information that can be provided by the supplier or manufacturer. It’s important to discuss the following parameters to ensure that the robot will meet your specifications:

| Application | Know in detail each step of the task the robot will be expected to perform and the materials it will handle to ensure the robot is the right type for the job. |

| Environment | Environmental conditions can play a critical role when determining the equipment needed to meet performance and longevity requirements. |

| Payload | The total weight the robot can manage is known as the payload. To ensure the pick and place robot can handle the payload, it’s important to know the weight of the heaviest object the robot will be required to lift combined with the weight of the chosen end of arm tooling. |

| Axes or degrees of movement | The number of axes determines the direction that the robot can move. Tasks that require twisting and turning manipulations will require additional axes. |

| Reach | Since the robot will be mounted in the workspace, it will need the ability to reach all the areas from which it is required to pick, as well as the area where it will place the object. Any obstacles or obstructions that it will need to reach around should also be considered when determining required reach. |

| Speed | A high-speed robot will be needed in high-volume applications, so if this is important, ensure that the robot offers the speed that is required for the highest efficiency and throughput. |

| Repeatability and consistency | These parameters refer to the pick and place robot’s ability to select objects and place them in a particular location or pattern every single time. The higher the repeatability, the more accurate the robot will be, which may be essential in assembly and other applications where consistency or high quality is imperative. |

| Proof of concept | Proof of concept simulations and testing may be necessary to assure the system design performs as expected under real world conditions. |

| Safety | A risk assessment must be performed to assure the robotic system meets safety requirements and regulations. |

| Other considerations | Vision systems should also be considered for inspection or pick and place applications that require sorting by size, shape, color or identifying markers. These accessories are typically an additional component and will likely be an add-on cost. |

The Benefits of Pick and Place Robots

Industrial users that install a properly selected pick and place robot can expect to see a lot of advantages due to the high speeds and accuracy provided by robotic automation. Some of the most noteworthy benefits include:

- Speed: Pick and place robots move at high speeds, which helps increase productivity in all applications, reducing bottlenecks and increasing throughput.

- Consistent accuracy: Robots are programmed to perform a specific task and they do not deviate from programming, so there is little chance of error, reducing scrap, waste and rework.

- Improved quality: Because robots perform programmed tasks with accuracy, pick and place robots used for packaging, assembly, inspection and other functions will do so without making mistakes, which leads to improved quality of finished products.

To increase the efficiency of your pick and place application, please contact JHFOSTER to determine which type of robot is best suited for the job.