Does My Process Need an Electric Actuator?

An Actuator is part of a device or machine that helps it to achieve physical movements by converting energy (hydraulic, electrical or air) into mechanical force. It is a component in a machine that enables movement.

What are some types of Actuators?

- Servo motor

- Stepper motor

- Linear motor

- Air pressure

- Fluid pressure

How does an Electric Actuator work?

Basically, an electric actuator is a mechanical device used to convert AC or DC electricity into kinetic energy in a linear or rotary motion. They vary widely in size and capability with rotary and linear being the most common types. Typically, rotary actuators can rotate continuously or oscillate while linear actuators move along a straight line in a back-and-forth motion.

Where are Electric Actuators used?

They are typically part of manufacturing, materials handling, food and beverage, packaging and palletizing. Electric Actuators are used in machine tools, conveyors, robotics and many other industrial machines and fixtures.

What are common types of Electric Actuators used in the Manufacturing Process?

- Rotary Actuator

- Gripper

- Linear Motor

- Rod-Style

- Rodless

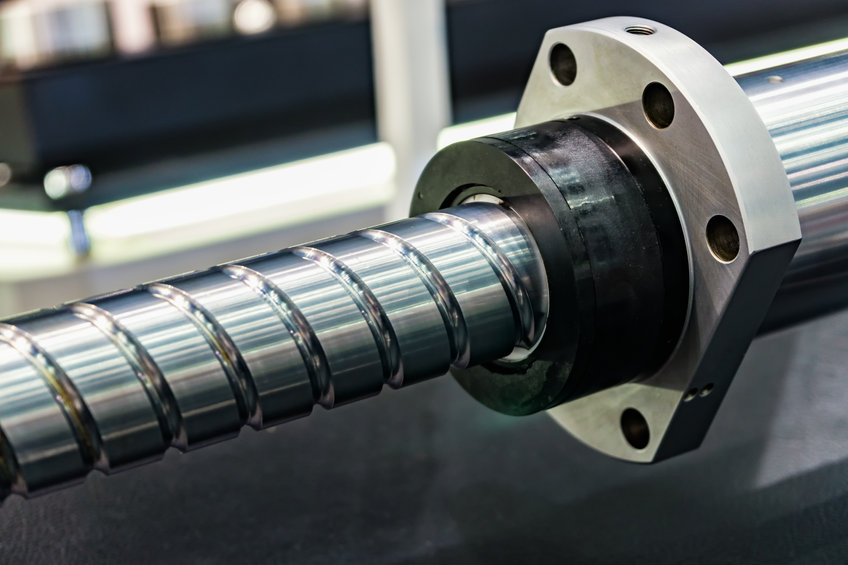

- Ball Screw

- Belt Drive

- Servo

What are the advantages of Electric Actuators?

Electric Actuators provide accurate control and positioning. They help to adapt machines to flexible processes. They are typically inexpensive to operate. Electric Actuators are often part of an energy efficient electric system.

How are Electric Actuators used in the Manufacturing Process?

Manufacturing plants use Electric Actuators in material handling. Examples include cutting equipment that moves up and down as well as valves that control the flow of raw materials. Robots and robotic arms in the manufacturing industry use Linear and Rotary Electric Actuator systems to achieve movement. Actuators can be combined to create multi-axis robots, which are used for pick and drop applications as well as conveyance. The Actuator allows the robots to have smooth, accurate and swift movements. These movements make it possible to safely pick and drop components and pieces from the conveyor line.

What if I have questions about Electric Actuators?

At JHFOSTER, one of our technicians would be happy to speak with you about choosing the right Electric Actuator for your process. Our expertise is in working with our clients to help them achieve optimal efficiency in their facilities. JHFOSTER is a leading distributor of automated systems and robotics. If you have inquiries about automated machines using high-quality Electric Actuators, please contact a member of our team.

A JHFOSTER representative is available at 651.998.7294 or 855.688.0043