A Brief Guide to Electric Actuators

One major component that makes automation possible is electric actuators. These mechanical devices convert electricity into kinetic energy using either rotary or linear motion.

Electric actuators work like other types of actuators. The only difference is that it uses electricity as its input. Electricity powers a motor, triggering specific components into motion. The final output is mechanical energy.

These components power a functioning electric linear actuator:

- Power Source – can either be AC or DC voltage

- Controller – ensures that the system performs the functions necessary by sending signals to the drive

- Drive – takes signals from the controller and provides the correct current and voltage to the motor to make accurate movements

- Motor – takes electric energy from the drive and produces mechanical power, often by rotating a shaft

- Actuator – the component that physically moves (see types below)

Types of Electric Actuators

Rod-Style Actuator

Rod-style actuators produce motion by retracting and extending a rod from the housing. With rod-style actuators, the load moves in two ways:

- The load moves by being attached to the rod

- The load is pushed or pulled by the rod

This type of electric actuator is perfect for inserting and pressing. These are also the go-to choice for moving loads that require end-to-end positioning, high speeds, and high force.

One primary advantage of rod-style actuators is their enclosed housing. It prevents liquids and other contaminants from entering the rod opening. That’s why most rod-style actuators generally have high IP ratings against water and other liquids.

Rod-style actuators are found in various fields like automated tables and beds in modern care centers. They are also used in the automotive industry to open car doors, guards, and hoods.

Rodless Actuator

The primary difference between rodless and rod-style actuators is how it carries a load. While rod-style actuators push or pull a load using a rod, rodless actuators transport it by using a belt or a screw. This method gives the rodless actuator the following advantages:

- Support for high loads and moment forces

- Smaller footprint for similar stroke length

- Eliminates the risk of rod bending and buckling

Its general design of having a standard piston extending entirely outside its retracted length allows it to provide exceptional results not possible with a rod-style actuator. This design makes rodless actuators perfect for packaging, cutting, assembly, and electronic manufacturing.

Pneumatic vs. Electric Linear Actuators

Pneumatic Linear Actuators

The main difference between pneumatic and electric actuators is the type of source. Pneumatic linear actuators utilize compressed gas. The gas is pumped into one end of the cylinder and then pushed out on the opposite end. This action pushes a piston forward, which then drives the load.

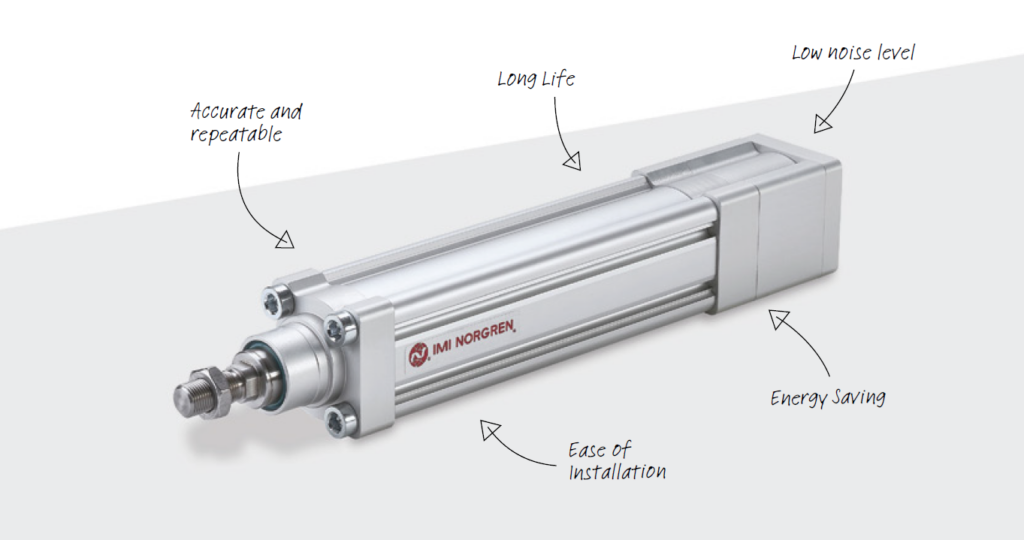

Pneumatic linear actuators are rod-style actuators with an internal rod that extends outside the casings (cylinders) to move the load forward. For this type of actuator, the bore and rod are round.

This linear actuator is found mainly in industrial settings, often in automated systems and machinery. It’s usually part of manufacturing, palletizing, materials handling, food and beverage, and packaging.

Electric Linear Actuators

Electric linear actuators rely on electricity, with motors acting as their source. Unlike pneumatic linear actuators, they don’t have a piston and use a screw or a belt instead. Electric actuators tend to be more expensive than most other types, but they are designed to be far less costly to operate.

Electric actuators are either used alone or combined to perform multiple tasks in sequence, such as reaching, lifting, rotating, and tilting. They also provide high-speed, accurate, and repeatable position control, generating a force of between 2,000 and 4,000.

Electric linear actuators are a good choice for automated systems, semiconductor manufacturing, medical devices, and food and beverage processing.

Common Actuator Mounts

Choosing the right mounting type can affect the way a linear actuator performs. The following are the most common mounting types used by linear actuators.

Clevis Mounting

One popular mount for electric linear actuators uses a clevis and a mounting pin. There are no brackets or any other kind of support to stop the movement. This enables the actuator to pivot from both sides.

Trunnion Mounting

This type of mount uses a customized mounting block placed at the front or rear of the actuator. This mounting technique allows the body and the cylinder to move. Trunnion mounts are often used in ATV or UTV attachments.

Rod End Bearing Mount

Rod end bearings are called universal joints. A ball bearing insert allows a rod or a bolt to pass through it to be misaligned to a limited degree. It’s usually an angle other than 90 degrees. This mount type is found in window openers and steering columns in automobiles.

Carriage Mount

Carriage mounts for rodless actuators have a fixed body and sliding carriage. They are most useful for applications that require high force, load guiding, and low to moderate speed. They also come with hand control and power supply.

Real-World Applications for Electric Actuators

Here are some examples of the real-world uses of electric actuators.

- Food and Beverage Manufacturing: Electric actuators are quiet and clean. Some are corrosion resistant and have a smooth design with little to no crevices where dirt or bacteria can accumulate. These make electric actuators perfect for sensitive industries like food, beverage, and medical manufacturing.

- Robotics: The automation industry relies on electric actuators. Actuators enable automated systems to maintain production quality and accuracy. This is because electrical actuators can control and repeat precise movements.

- Valve Operation: Processing plants that incorporate valves to manage the flow of raw materials rely on electric actuators due to their ability to provide exact actions and control.

- Heavy Machinery: While heavy equipment often uses hydraulics, machines with direct contact with food, beverage, medical devices, and semiconductors rely on electrical actuators. They do not rely on fluids to initiate motion and instead use electrical energy as a source.

Electric Actuators: A Vital Piece of Technology

Electrical actuators are amazing pieces of technology that help power many industries that make our daily lives possible. Its simple ability to convert electrical energy into kinetic energy allowed it to play a critical role in the modern world.

For example, electric actuators ensure that devices like a robotic manufacturing arm can move quickly and precisely. These actuators help your car’s engine control systems by regulating air flaps that manage fuel combustion.

Whether they’re rodless or rod-style by design, the uses of electric actuators are virtually limitless. It’s also worth noting that its quality, the work environment, and the type of mount used can affect how electric actuators work.

Choosing actuators and machines of high quality, durability, and overall efficiency is crucial. JHFOSTER is a leading distributor of automated systems and robotics. If you’re looking for automated machines using effective and high-quality electric actuators, get in touch with us. Our team can answer your questions and provide a quote.