Category: Uncategorized

Refrigerated Air Dryers Lower Compressed Air Dew Point

Widely used throughout manufacturing and other industries, air compressors generate significant amounts of water vapor during their operation. When water vapor goes unchecked, it can create moisture that wreaks havoc within the compressed air system, damage the tools and equipment the compressed air powers and compromise finished product quality. To avoid these potential problems, it […]

Industrial Power Systems Best Practices for Automation

As manufacturing companies continue to add robotics and automation systems throughout their facilities, having a reliable industrial power system is becoming more and more critical to the success of electrical automation projects. This blog will discuss the importance of power quality for industrial automation and provide best practices for efficient and effective factory power systems. […]

Automation Promotes Minimization of Waste and Energy Optimization

Automation technologies are often installed to increase efficiency, improve product quality and offset labor shortages, but there is another compelling reason to adopt industrial automation: It promotes minimization of waste and energy optimization. Although the industrial environment has never been considered “green” due to its high carbon footprint (some statistics say that industry accounts for […]

Legacy System Modernization with SCADA Integration

Many manufacturers rely heavily on their legacy systems, which are often customized to match the needs of the business, but as industrial technology continues to advance, many old-school legacy systems are becoming obsolete. However, legacy system modernization with SCADA integration can help manufacturers remain efficient, agile and viable in today’s competitive business climate. Why Legacy […]

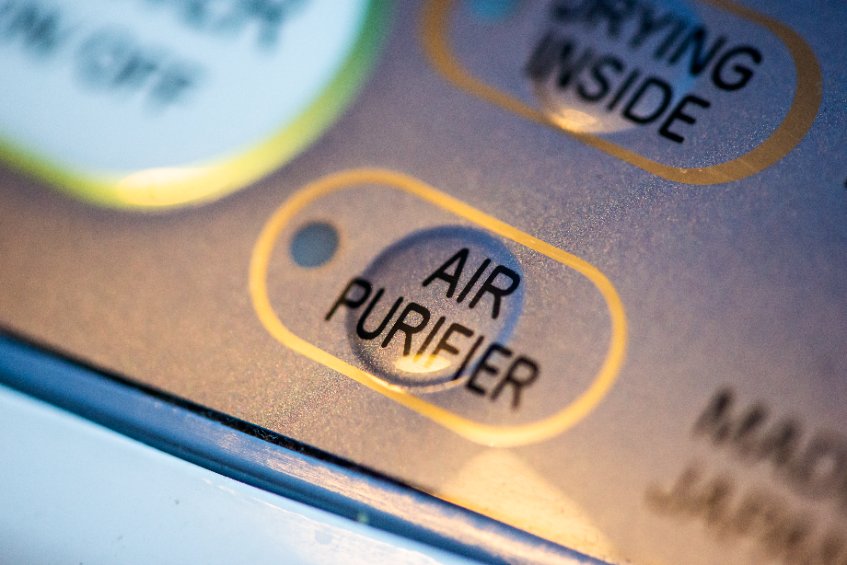

Achieving ISO 8573-1 Compliance for Compressed Air Quality

Compressed air is a staple in industry and is used for everything from powering air-operated tools and equipment to processing and packaging food and other products. While many facilities are concerned about the energy efficiency and performance of their compressed air system as it directly impacts the bottom line and productivity of the plant, compressed […]

Why Every Rotary Screw Air Compressor Needs an Air Dryer

Moisture is the enemy of every compressed air system as it can damage components including piping and valves, as well as the pneumatic machinery and tools it operates and can lead to the delivery of impure air that may result in contamination of finished goods. However, water vapor is an inevitable byproduct of the air […]

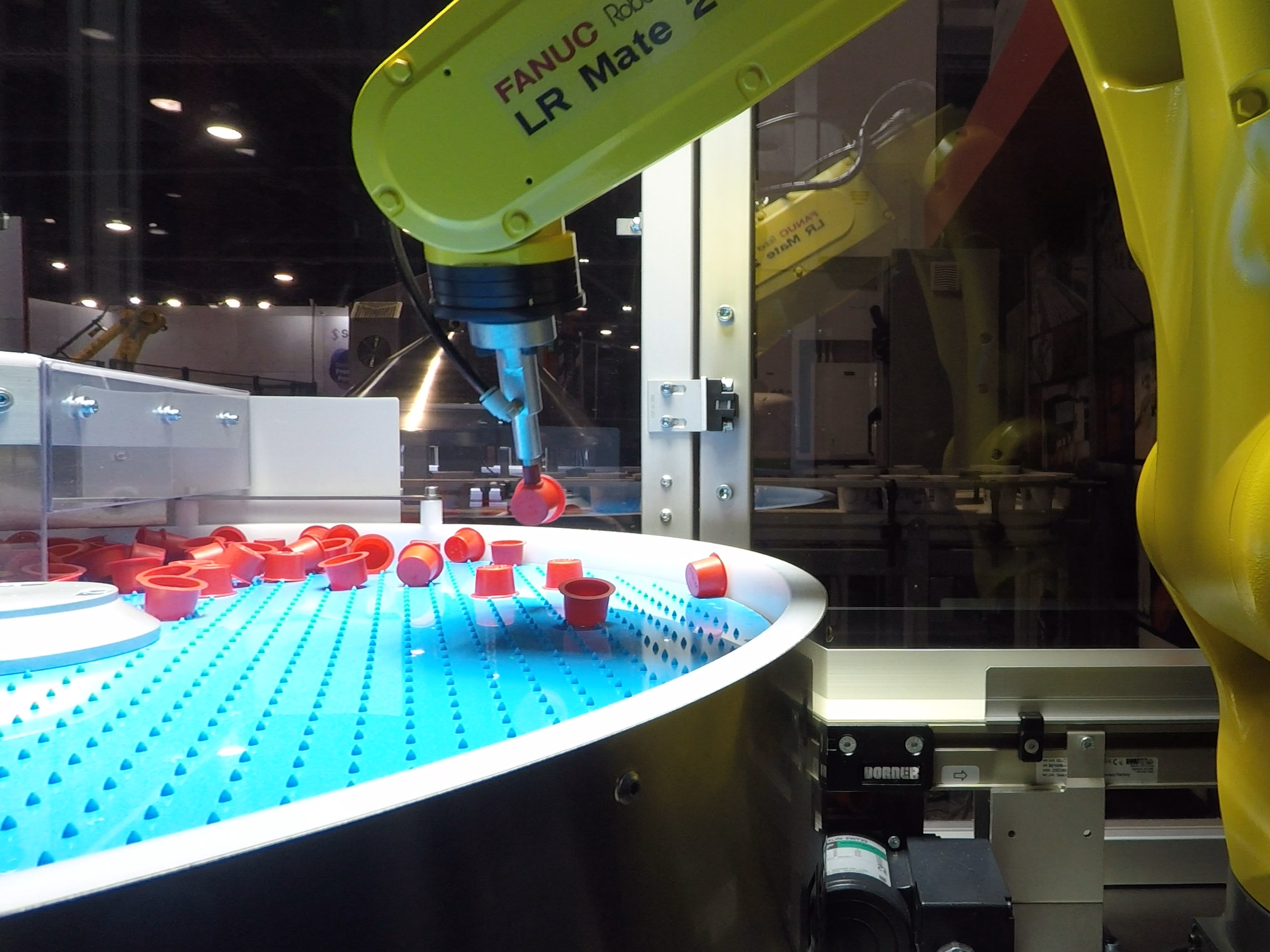

The Evolution of Automated Bowl Feeders

As trends in the consumer market have changed, so have the automated technologies used in manufacturing facilities. Due to current preferences in the consumer market, which demand high-quality, customized products available at a low cost and in the shortest time possible, manufacturers are using smart and flexible automated production equipment to produce their goods. However, […]

Automated Label Inspection Aligns with Industry 4.0 Initiatives

While many manufacturers are embracing Industry 4.0 initiatives in their processes, most have been slow to adopt advanced technologies in their label inspection operations. But, to fully reap the benefits Industry 4.0 has to offer, label inspection should also be automated with Industry 4.0-friendly technologies. However, until recently, a reliable, user-friendly label inspection system was […]

6 Benefits of Pick and Place Robots in Medical Manufacturing

Due to increasing market demand and strict governmental regulations, medical device manufacturers must maximize throughput while producing products with strict consistency in a contamination-free, sterile environment. For these reasons, pick-and-place robots present an ideal solution for material handling, assembly and other operations in this unique industry. The Unique Needs of Medical Device Manufacturing Like most […]

10 Impactful Benefits of Proper Safety Guarding

Industrial facilities are active places and host a variety of risks – from slips and falls to hazardous chemical use and storage to traveling forklifts to machinery with moving parts – that can injure or potentially kill employees. Accidents caused by these and other dangers can not only incapacitate workers, but they can also result […]