Category: Safety

Boost Productivity with Expert Cobot Integration

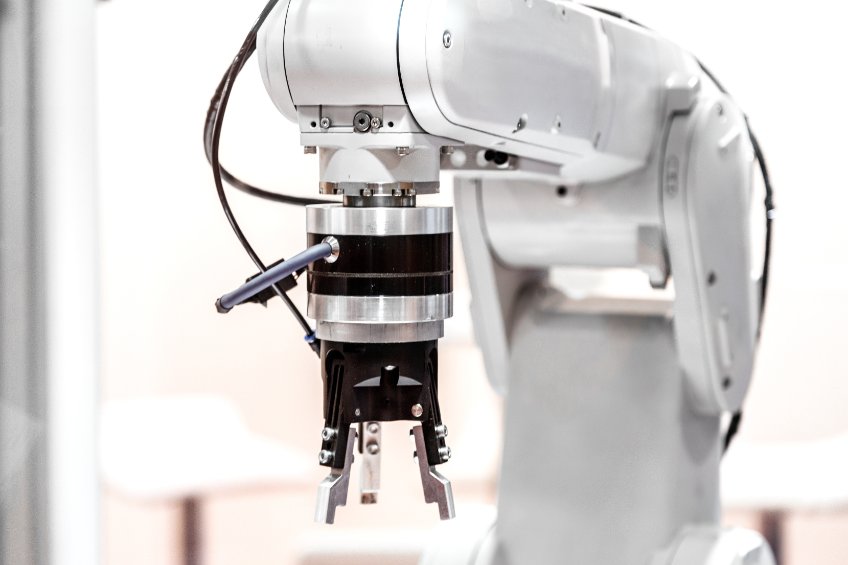

Start working faster, smarter and more efficiently. If you’re facing challenges like labor shortages, production bottlenecks or poor finished product quality, collaborative robots (cobots) offer a flexible and cost-effective automation solution. As your partner in automation, JHFOSTER will guide you from the initial evaluation to seamless integration to long-term support. What Is a Collaborative Robot? […]

Top Safety Considerations for Robotic Systems Integration

When planning a robot or automation integration project, most businesses focus on the anticipated productivity gains; however, because robots and automated equipment are fast-moving machines and are often located in the busiest areas of the facility, industrial robot safety should receive equal attention in order to keep the workplace as efficient and safe as possible. […]

Machine Risk Assessments Boost Manufacturing Safety

Manufacturing facilities can be busy and dangerous places with fast-moving equipment, vehicles and people at every turn. Safeguarding employees, as well as the assets and equipment, should be the highest priority in industrial settings. Fortunately, a thorough machine risk assessment, conducted by an experienced safety management service professional, can boost manufacturing safety by exposing potential […]

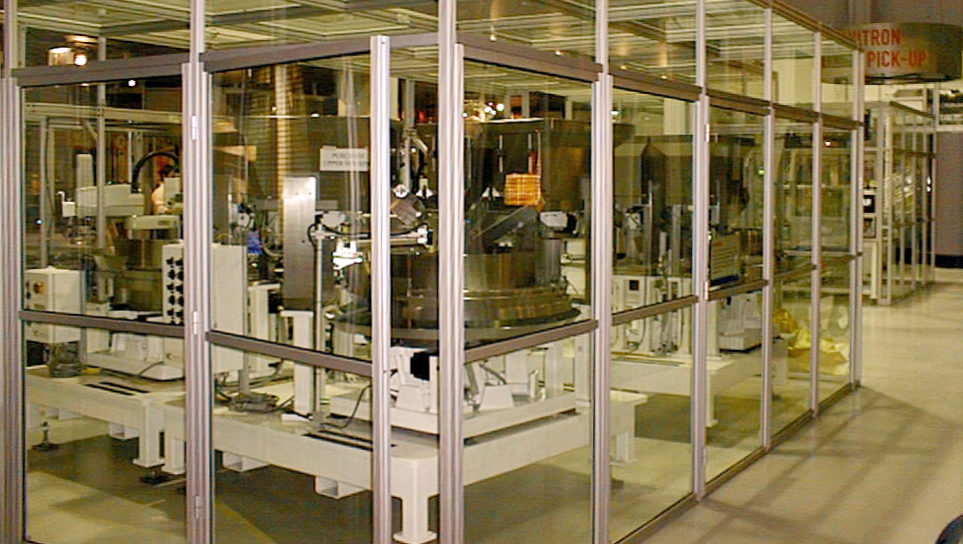

Proper Machine Safeguards Prevent Injury & Save Money

Industrial presses, cutting and power tools and machines with rotating or fast-moving parts are accidents waiting to happen, yet a lack of proper machine guarding is one of the most cited Occupational Safety and Health Administration (OSHA) violations each year. Safety precautions may be one of the best investments for an industrial facility, as they […]

Understanding the Safety Functions of Collaborative Robots

As the use of collaborative robots continues to expand in industrial workplaces, humans are more frequently sharing space with cobots, as they’ve come to be nicknamed. While collaborative robots are considered “inherently safe” by design, there are understandably concerns regarding the safety of human operators working in close proximity to swift-moving industrial equipment. However, advances […]

The Basics of Enhancing Safety with Electrical Control Panels

Electricity is a major safety hazard in the workplace, according to the U.S. Office of Compliance, which states that 400 employees were unable to work for 31 days or more due to electricity exposure injuries, 1,970 occupational injuries resulted from exposure to electricity and 154 fatalities occurred due to exposure to electricity in the workplace […]

Machine Vision: Why Your Industrial Robot Needs Eyes

Industrial robots safely and efficiently perform tasks that are either too repetitive, difficult or hazardous for human workers and do so in a way that enhances production by eliminating bottlenecks and increasing product quality, but without “eyes” to see what they’re doing, robotic applications can be limited. Since a robot can only perform a task […]

Integrated Safety Devices Prevent Workplace Hazards

Machine hazards are a reality for workers in industrial settings. The most challenging areas include those where potentially hazardous operations occur, such as around fast-moving machinery and robots and sources of power. In these locations injuries typically take place at points of operation and machine motion, as well as areas of power transmission, so machine […]

How to Successfully Introduce a Cobot into the Workplace

Collaborative robots, also called cobots, are getting a lot of attention because they address labor shortages and enhance productivity in a more cost-effective way than traditional industrial robots due to a simpler set up (think more along the lines of plug-and-play than complex system integration) and their ability to work alongside humans, while freeing them […]

Pneumatic Safety Components and Where to Apply Them

With the introduction of automated systems, building machines has become even more complex. This forced designers to devote more time to implementing newer safety standards. A good example of this is the revision of ISO 13849 in 2006, which meant that all machine builders now had to consider safety-rated components as part of their design […]