Category: Robotics

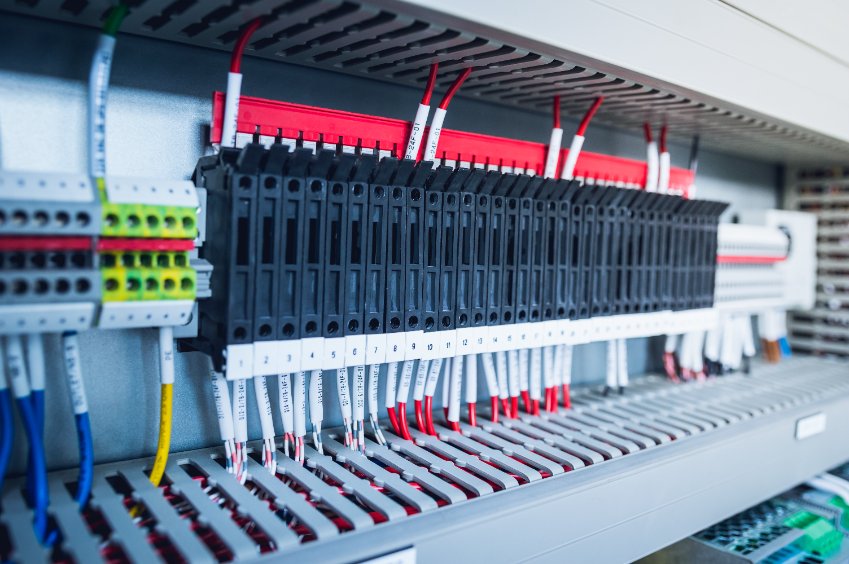

A Look at the Essential Components of a Motion Control System

Motion control, a sub-field of automation, is widely used for production lines and in robotics and other equipment where it is necessary to precisely control the speed, acceleration, position and torque of individual axes of a machine. It’s important to note that motion control is actually a system made up of several essential components that […]

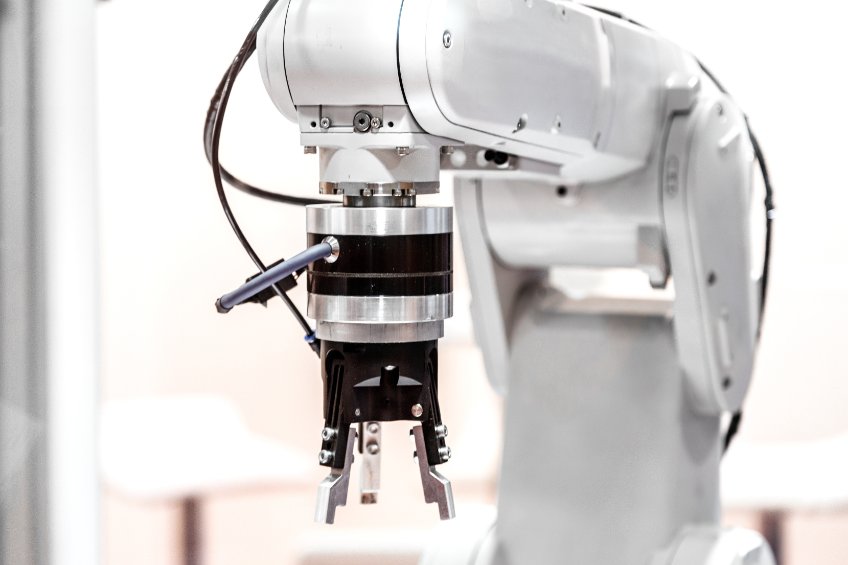

Should I Buy a Cobot or an Industrial Robot for Pick and Place?

Pick-and-place robots can help speed up the process of picking up objects and placing them in another location, increasing productivity and handling repetitive tasks while freeing up workers for more complex jobs in the facility. When you’re ready to automate pick-and-place activities, one of the first questions to address is whether to use an industrial […]

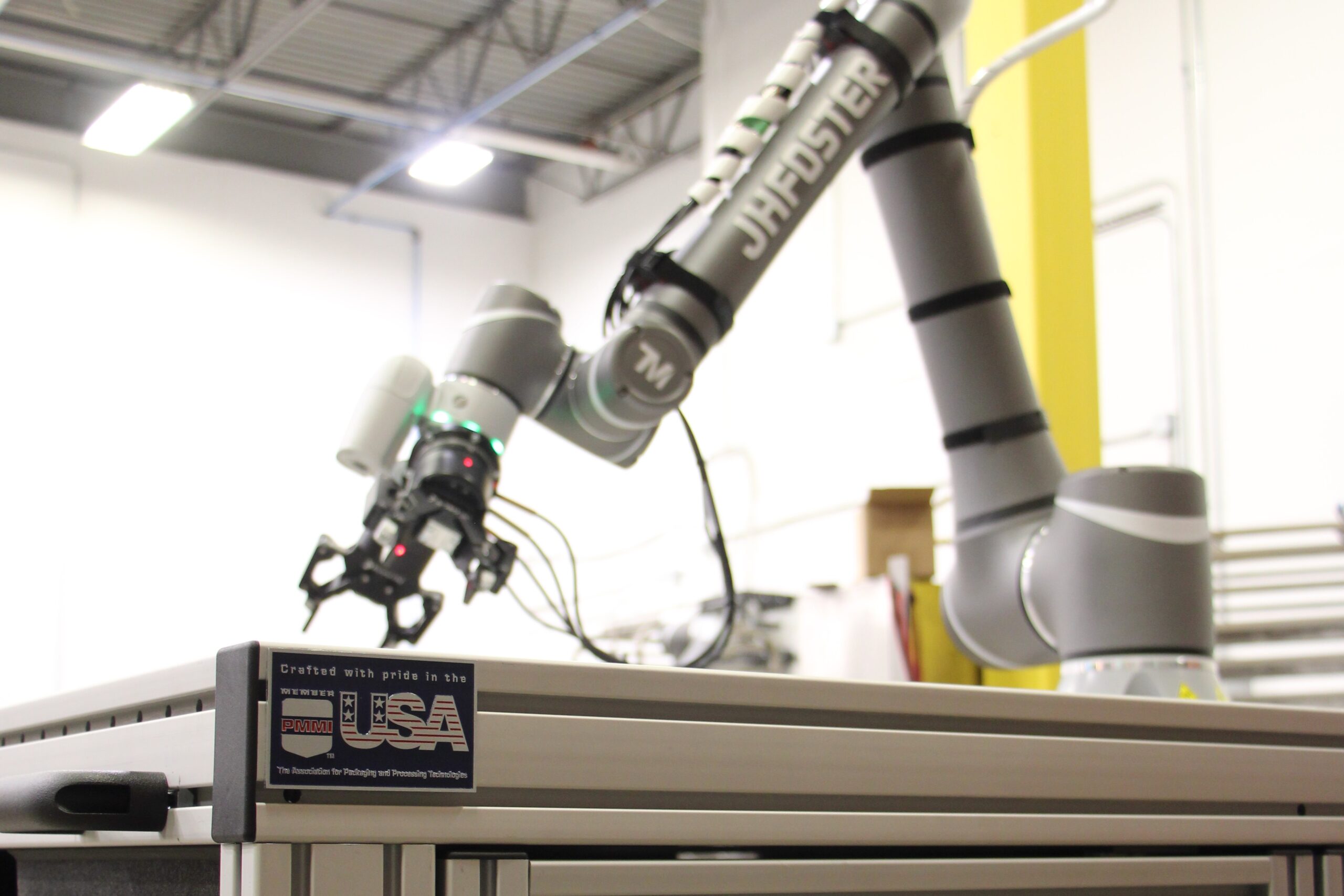

How to Successfully Introduce a Cobot into the Workplace

Collaborative robots, also called cobots, are getting a lot of attention because they address labor shortages and enhance productivity in a more cost-effective way than traditional industrial robots due to a simpler set up (think more along the lines of plug-and-play than complex system integration) and their ability to work alongside humans, while freeing them […]

The Differences Between Collaborative and Industrial Robots

As the world of robotics continues to become a fast-growing industry, so does the way in which we use them. Collaborative robots and industrial robots are quickly becoming staples in modern factories and businesses. In this article, we will explore the significant differences between cobots and traditional industrial robots. We will also discuss the benefits […]

Pneumatic Safety Components and Where to Apply Them

With the introduction of automated systems, building machines has become even more complex. This forced designers to devote more time to implementing newer safety standards. A good example of this is the revision of ISO 13849 in 2006, which meant that all machine builders now had to consider safety-rated components as part of their design […]

Cobots and the Future of Advanced Robotics in Manufacturing

Historically, automation in manufacturing has been a bit of a hammer. And as machine operators and plant managers alike know, not every problem is a nail. Fortunately, automation in manufacturing has advanced considerably over the last several years, bringing more agile, more cost effective, and safer solutions to manufacturing’s most wicked problems. Collaborative robots, also […]

Safety-Integrated Motion Control Allows Safety and Productivity to Co-Exist

Ultimately, the objective of any manufacturing operation is to produce product. Accordingly, corporate goals often focus on efficiency, quality and productivity. While some companies view safety as a necessary evil or, worse, a costly drain on productivity, top-tier manufacturers rank safety as a priority and embed it deeply into the culture of the company. Furthering […]

Are Collaborative Robots More Efficient than Workers?

The core motivation at the heart of technological advances is the desire to create tools that provide an improvement in our effectiveness as workers and, in turn, our business as a whole. As advances in technology continue, they broaden the boundaries and landscape of what was thought possible, and forces employers to be constantly reexamining […]

Who Makes the Best Industrial Robot?

That depends on your application and needs. Industrial robots are suitable for many tasks. From injection molding to packaging, the repetitive tasks within your business could be easily automated. The possibilities are nearly endless. However, if you’ve been researching different industrial robot manufacturers, you may be struggling to identify which one is right for you. […]

What Are the Signs Your Collaborative Robot Needs Repair?

Your collaborative robot, also known as a cobot, has been working hard to increase efficiency and reliability within production. This new technology has quickly paid for itself and has become indispensable for human coworkers working alongside the robot. Or perhaps you have used robotic technology for quite some time, and it has become a staple […]