Category: Robotics

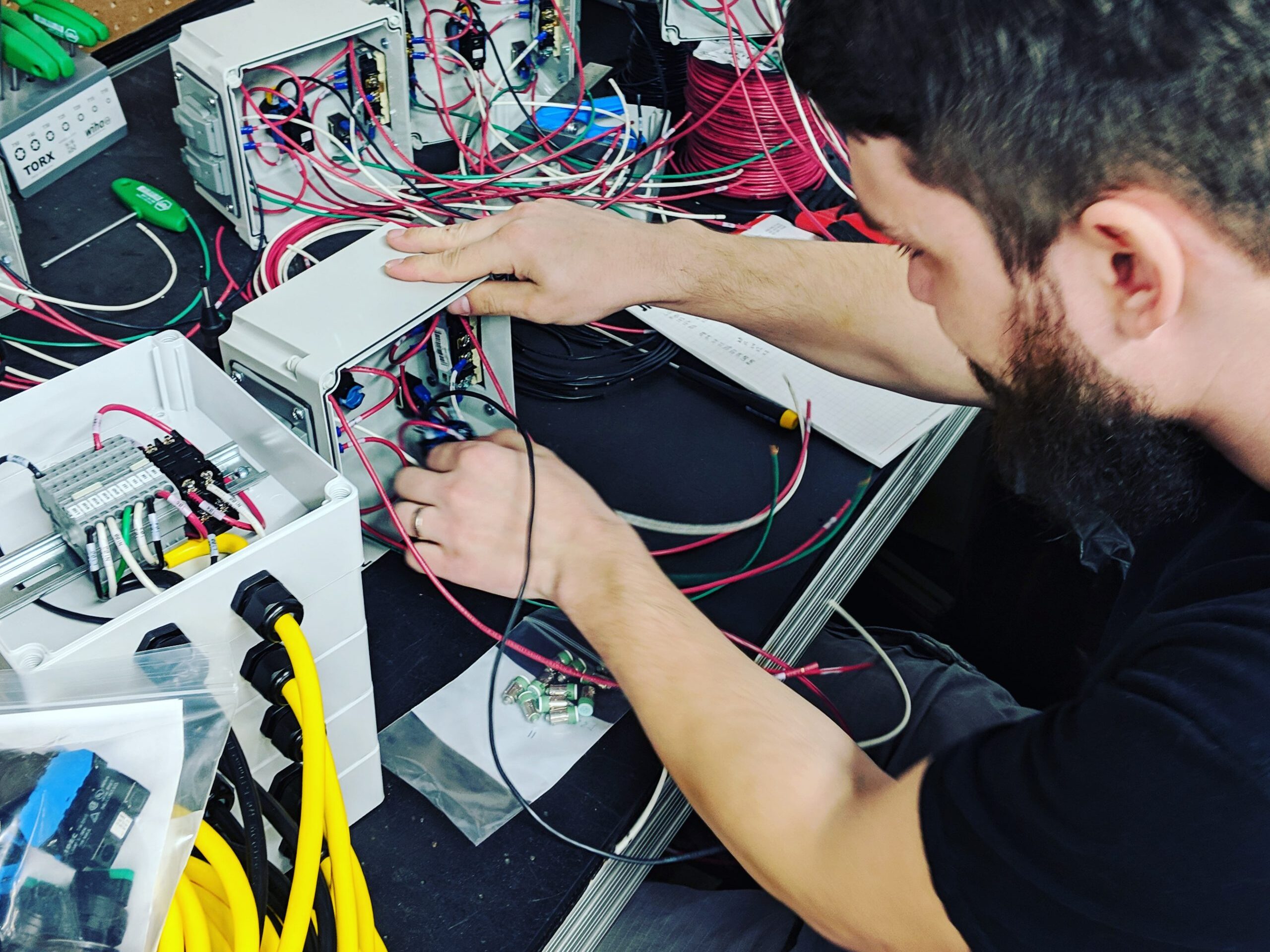

The Essentials of Industrial Control Panel Wiring

When it comes to industrial automation and control systems, the way industrial control panel wiring is laid out and managed plays a significant role in the performance, efficiency, safety and maintenance of the control panel and the equipment it operates. A thoughtful, well-organized wiring system can help increase the efficiency of the equipment, boost safety […]

Industrial Power Systems Best Practices for Automation

As manufacturing companies continue to add robotics and automation systems throughout their facilities, having a reliable industrial power system is becoming more and more critical to the success of electrical automation projects. This blog will discuss the importance of power quality for industrial automation and provide best practices for efficient and effective factory power systems. […]

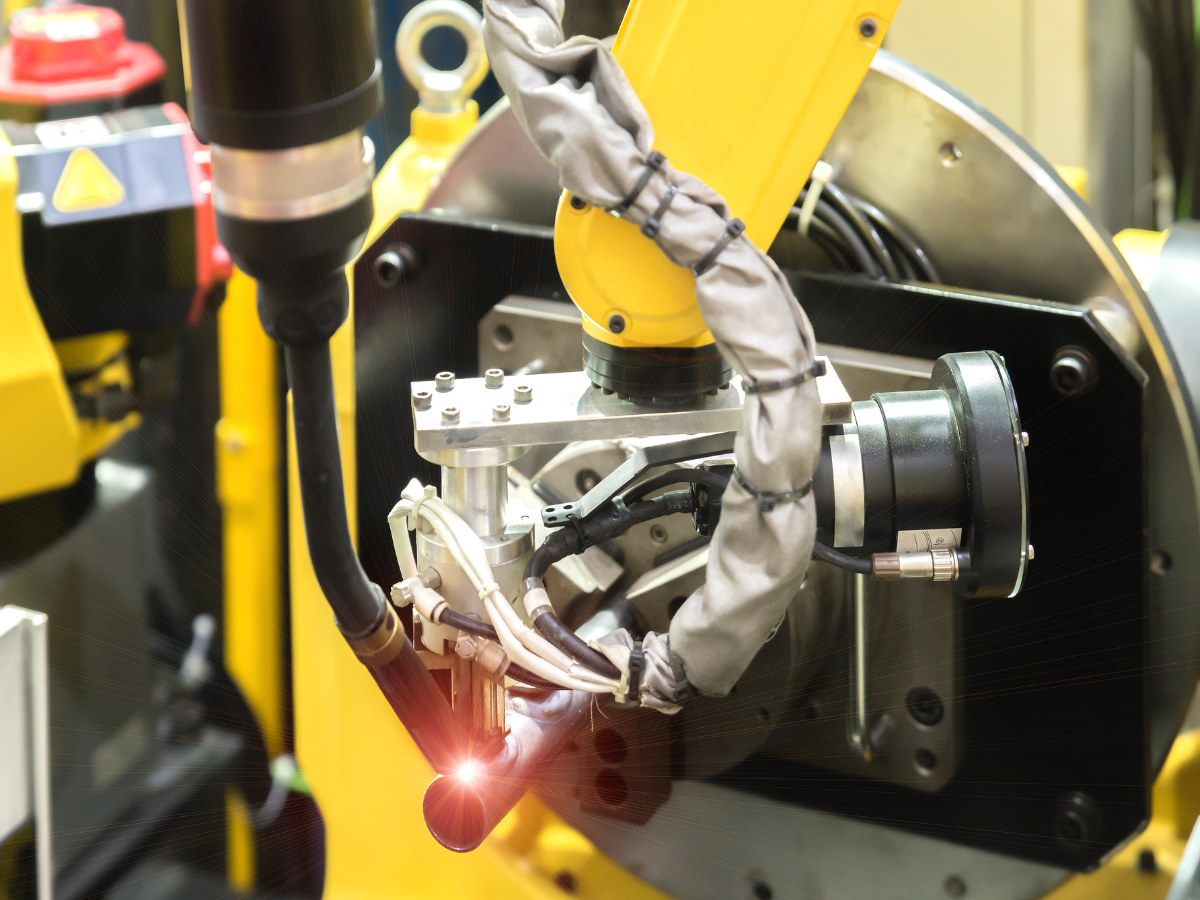

Customized End of Arm Tooling Transforms Applications of Robotics

End of arm tooling can enhance robotic functionality and maximize the efficiency and precision of a task. However, to ensure success of any project, selection of the right end of arm tooling is a critical part of planning a robotic system. Because there are so many applications of robotics, manufacturers have the choice between standard […]

Machine Risk Assessments Boost Manufacturing Safety

Manufacturing facilities can be busy and dangerous places with fast-moving equipment, vehicles and people at every turn. Safeguarding employees, as well as the assets and equipment, should be the highest priority in industrial settings. Fortunately, a thorough machine risk assessment, conducted by an experienced safety management service professional, can boost manufacturing safety by exposing potential […]

How the Degrees of Freedom of a Robot Define Its Capabilities

Industrial robots are reshaping the manufacturing industry because they maximize quality, efficiency, speed and throughput while reducing costs and helping to manage the ongoing labor shortage. So, as more manufacturers consider robotics for their operations, they may encounter the terms “number of axes” and “degrees of freedom” and find the terminology confusing. However, it is […]

Pick and Place Automation Revolutionizes High-Speed Manufacturing

Picking up parts, precisely positioning them and setting them down is one of the most common actions in the manufacturing industry. When done manually, the process can be time consuming, mundane and inaccurate. However, pick and place automation technology performs this tedious task with high speeds and great levels of accuracy, while freeing up manual […]

Robotic Assembly Lines Maximize ROI for SMEs

U.S. International Trade Commission statistics state that small and medium-sized enterprises (SMEs) are 60% less efficient than larger manufacturers. One of the reasons is that smaller manufacturers are less likely to embrace automation. According to an article in AdvancedManufacturing.org, SMEs often lack the resources needed to implement newer technologies that would help encourage efficiency and […]

A Deep Dive into Essential Control Panel Components

Control panels serve as the nervous system of industrial equipment as they are the central point of electrical distribution and control for machinery and processes in a manufacturing facility. Control panel components, such as fuses and circuit breakers, buttons, switches and other devices, enable operators to control, adjust and monitor the equipment that the control […]

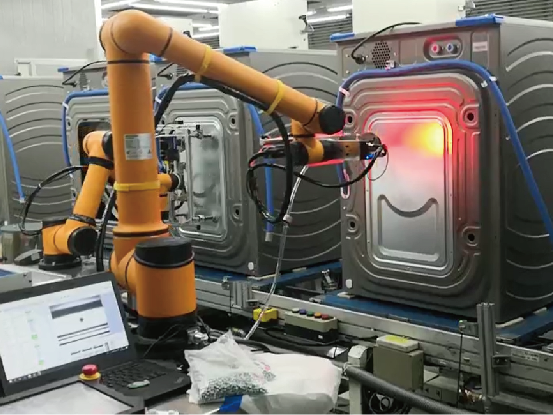

The Role of Robotic Arms in Modern Manufacturing

Robotic arms serve as the highly efficient “hands” of automated machinery in manufacturing operations. Developed to make tasks that were previously managed by human employees significantly faster, more accurate, highly repeatable and safer when properly integrated, robotic arms have revolutionized the modern manufacturing industry. This blog will explore the benefits and mechanics of robotic arms, as […]

Creating a Maintenance Strategy for Industrial Control Panels

Industrial control panels, which control and monitor electrical power distribution, as well as the safety of processes, are crucial to the reliable, safe and efficient operation of industrial automation equipment. Creating a preventive maintenance strategy for control panels can help minimize unplanned downtime, extend the life of the equipment and prevent failure and safety hazards. […]