Category: Compressed Air

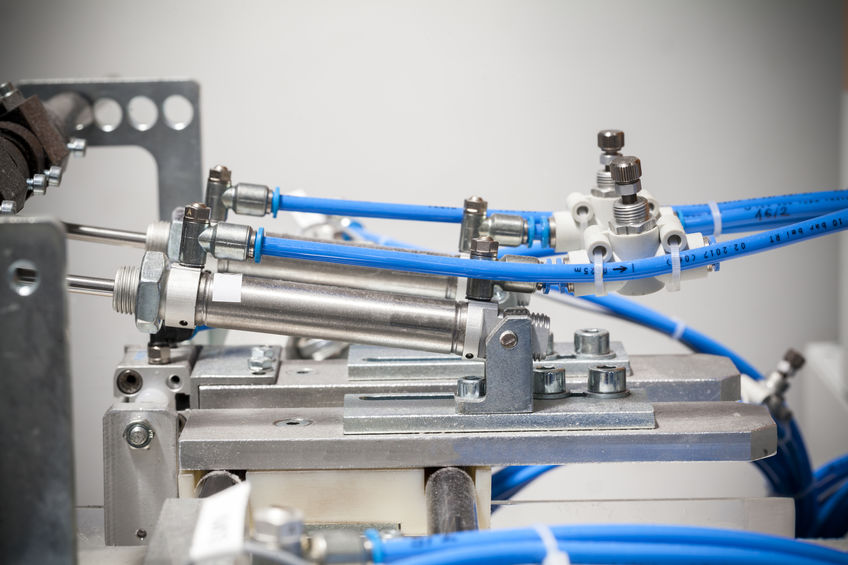

6 Essential Components of a Pneumatic System

Pneumatic systems use pressurized air to generate motion in many industrial applications, such as air-powered tools, end of arm tooling on robots, automated equipment and motion control systems. Pneumatics are widely used throughout industry and manufacturing because they are an effective, efficient and safe means of achieving movement and control. However, for pneumatic systems to […]

Pneumatic Systems: A Perfect Fit for Industrial Applications

Pneumatic, or compressed air-driven, systems have been used to achieve mechanical motion in industrial machinery for over 100 years and, in more recent times, pneumatic systems have advanced, expanding the range of pneumatic applications to include robotics, automated industrial equipment, processes and motion control in a variety of industries. The popularity of pneumatics stems from […]

Long Live Your Air Compressor

Air compressors serve as the heart of the compressed air system in many industrial facilities where they likely power everything from air-operated tools to valves to automated equipment. While proper preventive maintenance can go a long way toward keeping the heart of your operation beating for years to come, air compressors will eventually need repair […]

Pneumatic Systems: 101

Chances are if you work in an industrial facility, you’ve handled tools and equipment that are powered by a pneumatic system. These simple, yet powerful systems use clean, dry compressed air to create mechanical motion that powers tools, machinery and industrial automation systems. Learning about the components involved in a pneumatic system and how they […]

Compressor Controls Increase Efficiency and Cut Costs

Industrial facility owners must balance skyrocketing energy costs, aggressive sustainability goals and stiffening environmental regulations with cost reductions and increased demand for productivity. And, it is likely that the vast majority of these industrial facilities employ an air compression system to power equipment and processes. While air compressors do provide a convenient and clean supply […]

Top 5 Considerations for Proper Compressed Air System Installation

A well-designed compressed air system will provide many years of reliable service…as long as it has been installed in accordance with industry best practices. To ensure smooth, trouble-free operation for years to come, be sure to pay as much attention to the details of how the system is installed as you did to selecting a […]

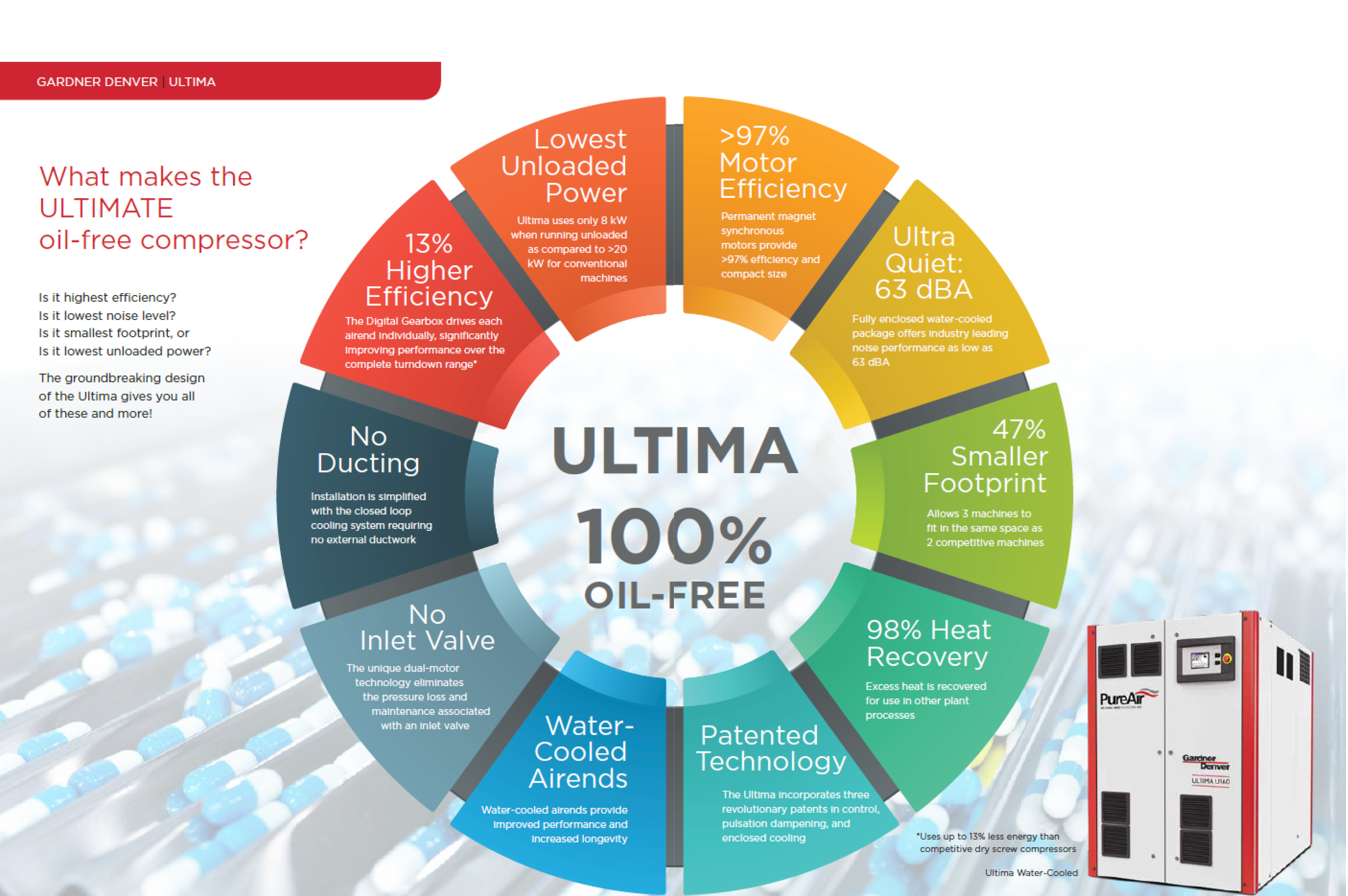

5 Misconceptions About Oil-Free Air Compressors

Oil-free air compressors are growing in popularity. In industries such as pharmaceutical, food, medical device, and electronics manufacturing, they have become a staple. Other industries employ them in an effort to avoid oil vapors that can damage sensitive production equipment or because oil-free compressors are reputed to reduce maintenance needs. While they do offer the […]

Section 179 Provides Significant Tax Breaks on Equipment Purchases

Industrial facilities that are considering the purchase of automation, robotic or compressed air equipment should be aware of the U.S. Internal Revenue Service (IRS) Section 179 Tax Deduction as it encourages businesses to invest in themselves by permitting an immediate and significant tax break on qualifying purchases for the 2023 tax year. Section 179 is […]

Strategies for Running an Efficient Compressed Air System

In industrial facilities, compressed air is a widely used resource because it’s a safe and readily available form of power for operating machine tools, material handling equipment and other pneumatic powered machinery. However, if not properly designed, operated and maintained, it can be a major facility expense as it requires 8 hp of electricity to […]

Best Practices for Medical-Grade Compressed Air

Medical-grade compressed air is vital to healthcare facilities as it is used for patient breathing treatments, anesthesia administration and as a power source for surgical tools in operating rooms. Because medical air is critical to positive patient outcomes, it is essential that medical-grade compressed air is of the highest quality. This article will discuss best […]