Category: Energy Audit

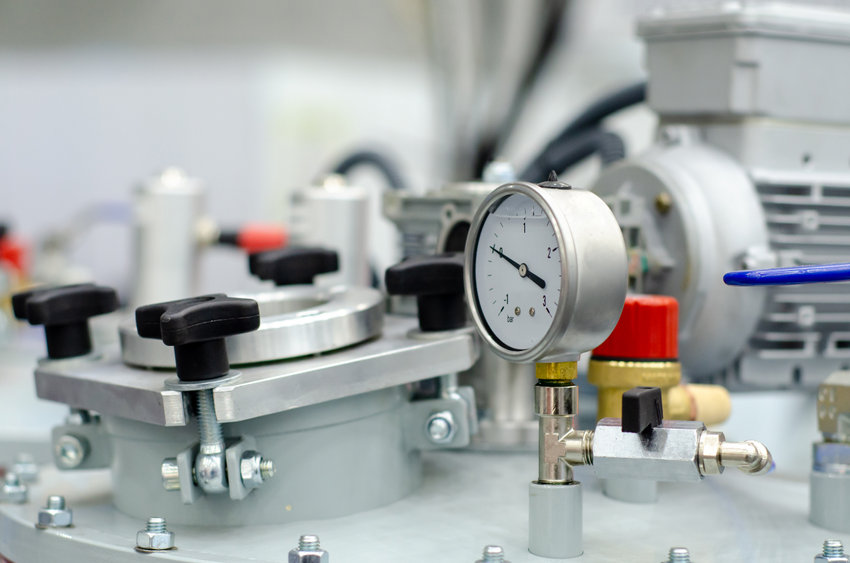

Proper Equipment and Compressed Air Quality Testing Assure Clean Air

High-quality compressed air is a necessity in most industries – and some in particular, such as food and beverage, pharmaceuticals and medical device manufacturing, must meet stringent ISO quality testing guidelines to safeguard the purity of their compressed air. Installing top-notch air compressors and components and regularly conducting industrial air quality testing will help ensure […]

What Should I Expect During an Air Energy Audit?

Compressed air systems are a necessity in most industrial facilities as they power many machines, tools and processes; however, they are notorious for consuming significant amounts of energy. As a matter of fact, the U.S. Department of Energy says that as much as 10% of all electricity generated in the United States is used by […]

Six Ways to Boost the Energy Efficiency of Your Pneumatic System

With a global focus on sustainability, resourceful manufacturers are finding inventive ways to slash their carbon footprint and, at the same time, their electric bills. Unfortunately, pneumatic systems, which provide the compressed air to drive machine tools, painting booths, material handling equipment and other machinery throughout the manufacturing industry, are often overlooked in efficiency efforts […]

Things to Check Before You Replace Your Air Compressor

Air compressors power many types of machines and processes in industrial operations, and many other industries. This is why any downtime related to equipment failure can adversely affect productivity, reliability, and the company’s bottom line. While you can do many precautions to prevent this, it’s also inevitable. No matter how good maintenance is, any piece […]

How To Determine the Cost of Compressed Air at Your Facility

Compressed air systems are a valuable resource for many businesses and industrial facilities. According to the United States Department of Energy, about 10% of electricity consumption is allocated to generating compressed air alone. Some facilities even go as high as 30% or more. It’s not surprising since compressed air is a useful on-site generated utility. […]

Why You Need an Air Energy Audit on Your Compressed Air System

Compressed air systems consume a surprising amount of energy. In fact, compressed air systems consume 10 to 15 percent of a company’s total energy bill on average. According to Quincy Compressor, “One horsepower of compressed air requires eight horsepower of electricity. With many air compressors running at efficiencies as low as 10%, there’s often plenty […]

Why and How To Perform A Vacuum Audit

Vacuum holds material in place, gathers up solids and liquids, provides transport, and keeps chambers and enclosures free from gases that would affect process performance. It’s essential in many production operations and a system that’s performing badly will impact costs and quality. Regular vacuum audits provide insight into how a system is running and identify […]

How To Use A CFM Calculator

Whether you use a calculator every day or you haven’t used one since high school, it’s probably a safe bet that you’d still be fairly comfortable using the device if you had to. If you’re ever in the market for an air compressor for your industrial facility, it would certainly qualify as a time when […]

How to Make Your Air Compressor Systems More Efficient

Anything you can do to make appliances run more efficiently is going to save you money in the long run. A well-running vehicle will get you more miles per gallon, saving you money at the gas pump. And an efficient HVAC unit will do more than just effectively cool and heat your property, but do […]

What Is a Pressure Drop and How Do You Prevent It?

Whether you’re running a small business or are in charge of a large industrial environment, air compressors of all types definitely have a place in your environment. A lot of organizations actually use air compressors as something of an energy source, using them to power both critical equipment and tools in a reliable and efficient […]