How To Determine the Cost of Compressed Air at Your Facility

Compressed air systems are a valuable resource for many businesses and industrial facilities. According to the United States Department of Energy, about 10% of electricity consumption is allocated to generating compressed air alone. Some facilities even go as high as 30% or more.

It’s not surprising since compressed air is a useful on-site generated utility. It can power tools, clean surfaces, and perform complicated tasks like operating pneumatic controls.

However, before you can take advantage of its benefits, you need to understand how to calculate its cost. In this article, we’ll explain the basics of compressed air pricing.

Compressed Air as One of the Most Expensive Uses of Energy

The cost of compressed air is one of the most expensive uses of energy in an industrial facility. It takes a lot of energy to compress air and make it available for use.

A typical breakdown of the cost components for a 100-horsepower (hp) compressor operating at 80% capacity might look like this:

- Electricity (70%)

- Maintenance (5%)

- Compressed air system leaks (20%)

- Other Operational equipment (e.g., filters and dryers) (5%)

As you can see, the vast majority of the cost (70%) is related to the electricity required to power the compressor. In terms of maintenance, 5% is considered very good for a compressed air system.

The last two cost components, leaks, and other equipment operations, are often overlooked but can represent a significant portion of the total cost. Compressed air leaks can account for 20% or more of the total cost of operating a system.

Determining The Cost of Compressed Air

Now that we’ve looked at the cost components of compressed air let’s look at how to calculate the cost. Here’s the formula used to calculate the cost of compressed air based on electrical cost:

Cost of Compressed Air = (bhp) x (0.746) x (# of operating hours) x ($/kWh) x (% time) x (% full-load bhp) / Motor Efficiency

The variables involved in this formula:

- bhp = brake horsepower or compressor shaft horsepower (Power required to run the compressor. Can be checked on the equipment’s specification details)

- 0.746 = the conversion factor from hp to kW

- $/kWh = cost of 1 kWh of electricity in dollars

- %time = the percentage of time that the compressor is running at full load

- %full-load bhp = the percentage of brake horsepower that the compressor uses while it’s running. This should be checked by monitoring the amperage draw on the compressor motor while in operation.

- Motor Efficiency = the efficiency percentage of the electric motor at this operating level.

Example 1:

Let’s say you have a 50-hp compressor that runs for 8,000 hours per year. The power cost is $0.10 per kWh, and the compressor motor is 80% efficient. The amperage draws on the compressor motor while in operation was measured and found to be 56 amps.

The cost of compressed air would be calculated as follows:

Cost of Compressed Air = (50 bhp) x (0.746) x (8,000 hours) x ($0.10/kWh) x (100% time) x (56% full-load bhp) / (80% motor efficiency)

Cost of Compressed Air = $20,888 per year

As you can see, the cost of compressed air can be high. In this example, it would cost just over $20,000 per year to operate the compressor.

Now let’s look at another example to see how changing some of the variables can impact the cost.

Example 2:

Let’s assume your manufacturing facility has a 100 hp compressor (requires 110 hpb), which operates for 7,000 per hour annually.

The machine is fully loaded 85% of the time (with motor efficiency being 95%) and unloaded the rest of the time (has 25% full-load hpb and a motor efficiency of 90%). The aggregate electric rate is $0.10/kWhr.

The cost when fully loaded:

((110 hp) X (0.746) X (7,000 hr) X ($0.10/kw-hr) X (0.85) X (1.0))/.95 = $51.396.00

The cost when partially loaded:

((110 hp) X (0.746) X (7,000 hr) X ($0.10/kw-hr)X (0.15) X (0.25))/.90 = $2393.00

Annual energy cost = $51,396.00 + $2393.00 = $53,789.00

Typical Lifetime Compressed Air Costs in Perspective

While the cost of compressed air can be high, it’s important to keep it in perspective. Most of the cost is related to electricity, which is a relatively stable cost.

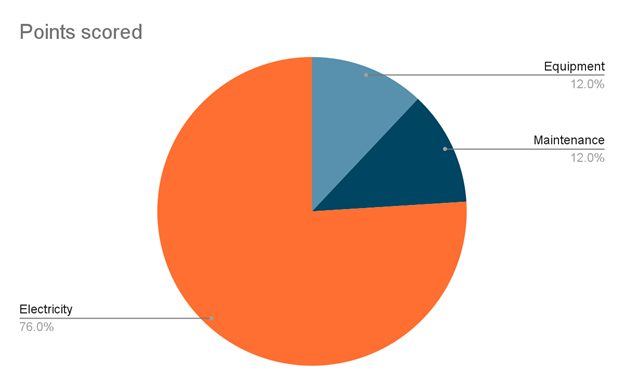

A 75 hp compressor operated two shifts per day for five days a week at an aggregate of $0.05/kWh for over ten years can look like this:

- Equipment: 12%

- Maintenance: 12%

- Electricity: 76%

In addition, the cost of compressed air is often a small percentage of the overall cost of production. For example, in a typical food and beverage plant, the cost of compressed air is often less than 1% of the total cost of production.

In most cases, the cost of compressed air is a relatively small part of the total cost of production. However, there are some instances where the cost of compressed air can be a significant part of the total cost of production.

For example, in a plant that uses compressed air for blow molding or for sterilizing packaging material, compressed air can be a significant part of the total cost of production.

Understanding the BestPractices Program

BestPractices is a program developed by the Compressed Air and Gas Institute (CAGI) to help companies understand how to optimize their use of compressed air.

The program provides companies with guidelines on reducing the cost of compressed air while maintaining or improving quality. By following the BestPractices guidelines, companies can save money while ensuring that they are using compressed air efficiently.

The BestPractices program can also help companies avoid potential problems that could lead to downtime or other production issues.

Final Thoughts

The cost of compressed air can be high, but it is important to keep it in perspective. Most of the cost is related to electricity, which is a relatively stable cost. Most importantly, monitoring this cost can benefit companies as it can help identify potential areas for efficiency improvement.

Additionally, the BestPractices program provides guidelines on how to optimize the use of compressed air, which can help companies save money while ensuring that they are using compressed air efficiently.

JHFOSTER is your partner for high-quality compressed air systems and services. If you have any questions regarding your compressed air systems and parts, please feel free to contact us today.