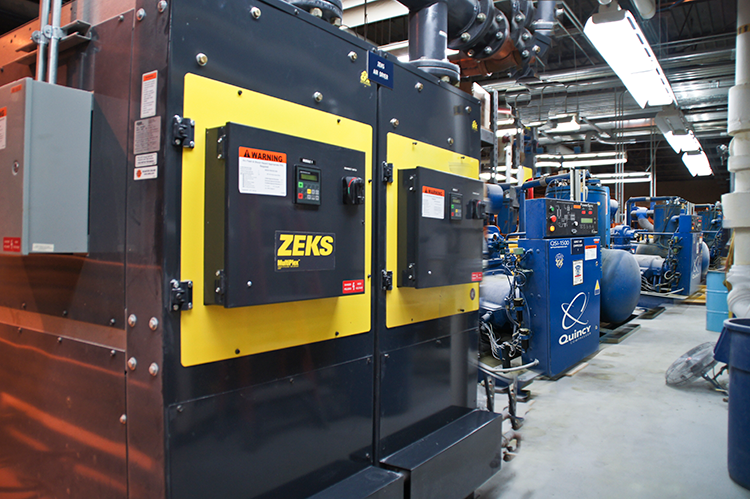

Category: Air Compressor

Leasing vs Buying Industrial Air Compressors

When it comes to factory operations, not every piece of equipment becomes owned by the company. Making lease arrangements sometimes offer cost savings and other benefits that fit better in the company’s budget. For industrial air compressors, the needs of the company should always be taken into consideration before deciding on whether to lease the […]

Best Applications for Compressed Air Systems

For compressed air systems, the types of applications for these compressors will depend on the industry. These systems may be used in automotive, aerospace, medical, food, mining, and many others. These industries may use several different types of compressed air for their operations that could come in various sizes. Companies in these industries may also […]

Safety Pointers When Working with Compressed Air Systems

Compressed air systems are used for varying industries, from agriculture to pharmaceutical manufacturing, requires workers to operate systems within safety parameters. Any sudden changes in pressure or malfunction equipment may cause an accident that could damage products or applications as well as injure workers. Practicing safety best practices allows workers to take all required precautions […]

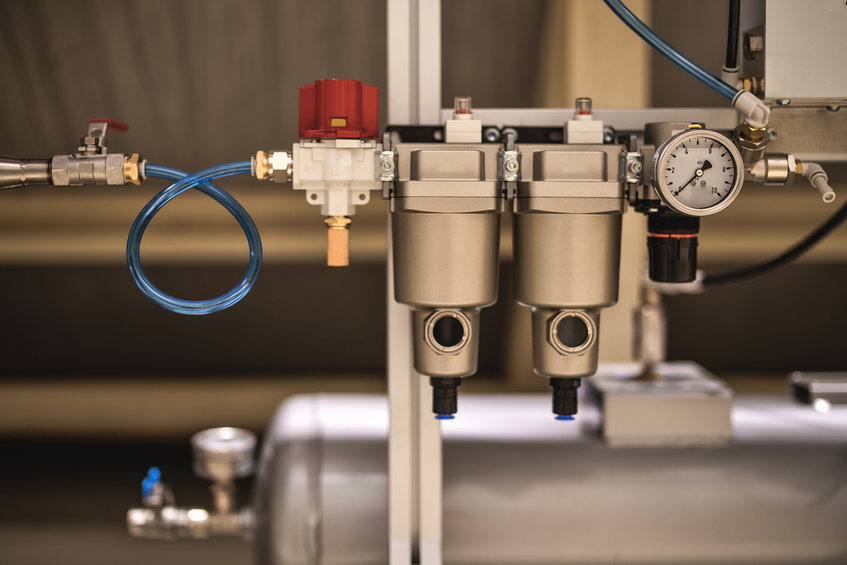

What are Particulate Filters for Air Compressors?

Mechanics recommend that you change the air filter on your vehicle so that its heating and cooling system continues to work effectively. HVAC service providers echo a similar sentiment when it comes to your home or office’s heating and cooling equipment. But there are various industrial appliances that require similar upkeep in order to continue […]

How IOT and Industry 4.0 Boost Compressed Air Systems

In factories, processing plants and elsewhere, if compressed air stops flowing everything stops. Actuators and pneumatic tools won’t work, conveyors don’t move powder, sprayers can’t apply coatings and so on. That puts the person responsible for the compressed air system at the center of the action, which is usually not much fun. The IOT and […]

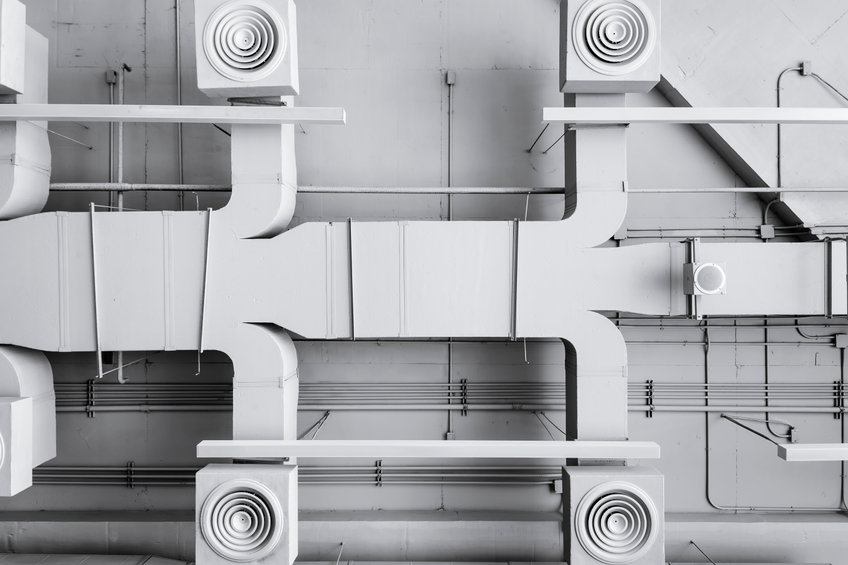

How to Make Your Air Compressor Systems More Efficient

Anything you can do to make appliances run more efficiently is going to save you money in the long run. A well-running vehicle will get you more miles per gallon, saving you money at the gas pump. And an efficient HVAC unit will do more than just effectively cool and heat your property, but do […]

Safe Operating Procedures for Compressed Air Systems

In the world of manufacturing, air compressors play a far more vital role in day-to-day proceedings than most people realize. But at the same time, it’s also one of the more dangerous pieces of equipment on a shop floor – which is why employees should proceed with extreme caution during their operation. Not only can […]

The Impact of Technology in the Air Compressor Industry

Technology simply continues to move markets and industries forward. And this includes the air compressor industry. Yes, while the average consumer may not associate air compressors with major advances in technology and innovation, compressed air systems have come a long way in a relatively short period of time, helping facilities become more efficient, safe, and […]

The Different Levels of Air Purity and the Processes that Require Them

According to the World Health Organization, poor air quality kills an estimated seven million people globally each year. If you needed a single statistic to help underline why air purity is critically important, let it be that one. Poor air quality is everywhere – from smoke or carbon monoxide in homes to the smog that […]

How the Industrial Internet of Things Enhances Compressed Air Systems

Also commonly referred to as the IoT for short, the Internet of Things is a term referring to a series of sensors and other objects that are embedded in everyday objects, all creating and sharing data with one another at all times. The most obvious example of this idea takes the form of the common […]