6 Benefits of Automated Palletizers in the Pharmaceutical Industry

Like most manufacturers, producers of pharmaceuticals are currently experiencing a growing demand for products while also struggling with labor shortages, making efficiency crucial in this ultra-competitive industry. Fortunately, automated palletizers can help offset labor challenges by significantly minimizing the need for human workers in pallet handling operations. As a bonus, by reducing reliance on manual labor, automated palletizers can also help pharmaceutical manufacturers enhance efficiency, output, consistency and safety.

What are Automated Palletizers?

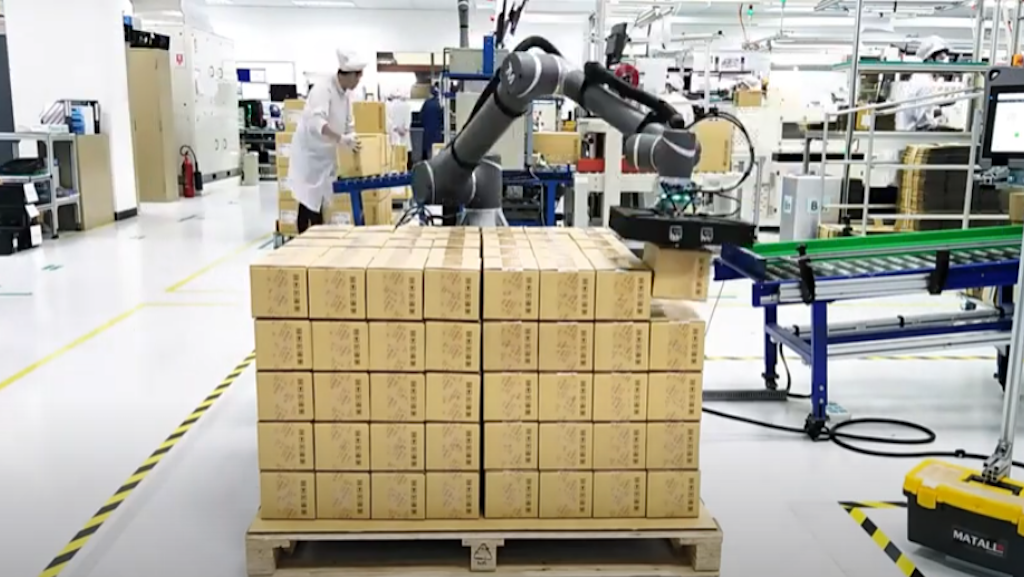

Robotic palletizers automate the process of stacking goods and products onto pallets. As items move down an infeed system or conveyor, the palletizer’s robotic arm picks up and orients one or more products and accurately places it on a pallet in a pre-programmed pattern. The palletizer will continue constructing layers of product according to the assigned program until the pallet is fully loaded.

The system will then place the finished pallet on an outfeed conveyor, removing it from the area and sending it to the next stage of the logistics process.

Many automated palletizing systems are capable of handling multiple tasks at once, such as picking and manipulating products for proper placement while also stacking them. They can be programmed to handle a range of applications, including standard cases, mixed pallets or bags, and do so at high speeds – with some running up to 2,000 cycles per hour.

6 Benefits of Automated Palletizers in the Pharmaceutical Industry

High speeds coupled with the ability to manage multiple steps of the palletizing process make automated palletizers incredibly efficient compared to manually handling the same tasks, which provides the necessary productivity boost, as well as several other benefits, sought by today’s pharmaceutical manufacturers. Below are six of the greatest advantages of automated palletizers for the pharmaceutical industry:

- Offset Labor Challenges: Labor shortages are a problem throughout the manufacturing sector and retaining manual workers in palletizing operations can be especially difficult since the operation is boring and requires physical strength and endurance. Using automated palletizers can alleviate this issue as it minimizes the need for manual labor so existing employees may work elsewhere in the facility where they will provide more value to the operation and perform more rewarding duties.

- Increased Efficiency and Throughput: Automated palletizers operate at greater speeds than manually performing the same tasks, which enables higher levels of efficiency and throughput in the same amount of time, significantly boosting a facility’s output and allowing pharmaceutical manufacturers to meet production goals and keep up with growing demand for medications and other products. The use of automated palletizers also helps reduce bottlenecks in the facility and increases operational agility. Enhanced efficiency and increased throughput result in shorter lead times and speedier order fulfillment.

- Improved Consistency: Because automated palletizers are pre-programmed to stack products in a specific pattern, they are especially helpful in pharmaceutical production and packaging where there is no room for error as the industry is highly regulated by government entities for consistency and accuracy as the products are intended for human healthcare.

- Minimized Product Damage: In the pharmaceutical industry, there is no allowance for damage to products or the packages that contain them as the sensitive products require careful handling per government regulations. Automated palletizers can help prevent product damage as they are programmed to stack pallets in the pattern that is most suitable and provides the most protection and stability. In addition, the consistency and accuracy afforded by automation is superior to that of human workers who may grow tired and careless when stacking pallets and damage products or packages.

- Greater Flexibility: As the trend toward personalized medications and smaller scale pharmaceutical manufacturing continues to grow, flexibility and agility are major challenges for providers of pharmaceutical products. Automated palletizers are easy to program and reprogram to meet the needs of smaller production and packaging runs. Operation of automated palletizers can also be scaled up to manage ramped up production if the pharmaceutical company begins to see significant growth.

- Enhanced Compliance and Traceability: When automated palletizing systems are combined with the proper software and data integration, real-time tracking and monitoring becomes possible, helping pharmaceutical manufacturers more easily comply with strict regulations for traceability and serialization. These capabilities also enhance product integrity and help prevent counterfeiting, which are major concerns for producers of pharmaceuticals.

- Improved Safety: Any time you remove manual laborers from a process – especially one that involves bending, lifting and twisting – the safety record of the operation will improve as incidences of repetitive motion injuries will be minimized. This will also help reduce costs associated with worker compensation claims, insurance and medical expenses.

Finding an Automated Palletizing Solution

Automating palletizing operations can help pharmaceutical manufacturers and packagers meet growing demand for products, while also offsetting challenges associated with the current labor shortage. In addition, automated palletizers provide efficiency, flexibility and compliance for businesses in the pharmaceutical industry by increasing throughput and consistency, reducing product damage and enhancing product quality, while also improving the facility’s safety record. However, when selecting an automated palletizing system for sensitive and regulated pharmaceutical operations, it’s important to choose a supplier that can offer expertise with pharmaceutical automation. Experience selecting, installing and maintaining automated equipment, including automated and robotic palletizers for pharmaceutical manufacturers and packagers, makes JHFOSTER a go-to, professional and reliable source for palletizing solutions. Please contact us today.