Asset Monitoring with a Simplified Solution

Traditionally, asset monitoring, the practice of collecting and analyzing data about the health of equipment, was time consuming and labor intensive when managed manually or complicated to set up when using disparate Internet of Things-enabled sensors and devices. However, a modern, simplified solution – the Asset Monitoring Gateway with SNAP ID from Banner Engineering – allows users to begin monitoring equipment in minutes so they can quickly start making informed decisions that help increase productivity, save energy and prevent unexpected maintenance issues. This blog will outline the simplified process of getting started with this user-friendly technology and highlight the benefits asset monitoring can bring to a facility.

Asset Monitoring for Beginners

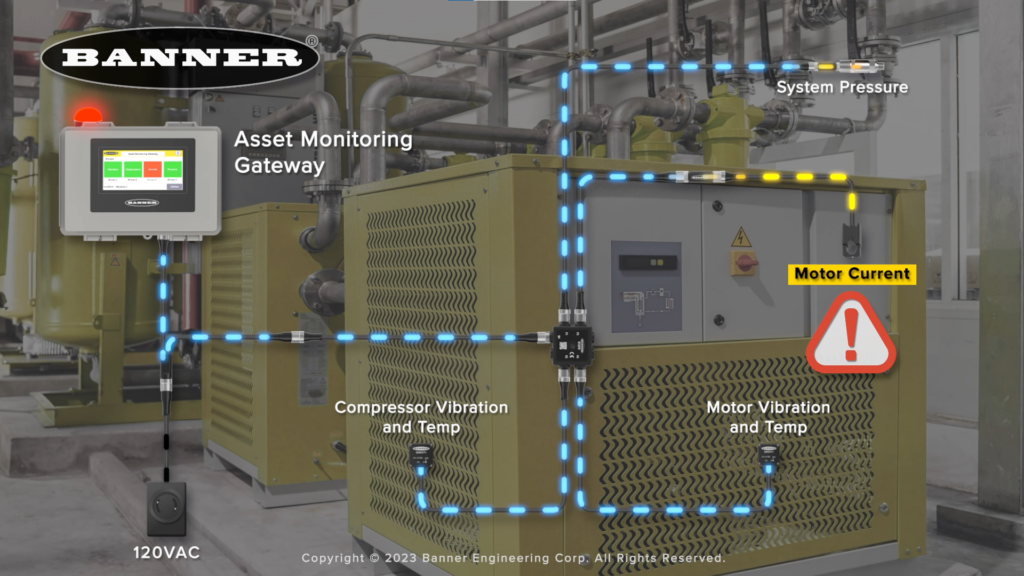

Asset monitoring is the real-time observation of the performance of plant assets, such as pumps, motors and gearboxes, air compressors, HVAC units, and dust-collection equipment, with the ultimate goal of minimizing downtime and optimizing usage.

Important variables such as vibration, differential pressure, temperature, humidity, tank level and other specifications are collected via sensors that are connected to the assets. Critical data is then presented to operators and technicians, allowing them to make informed decisions about maintenance and usage in an effort to prevent unplanned downtime, increase uptime, optimize production schedules and minimize utility bills.

Asset monitoring was traditionally performed manually whereby technicians made rounds on critical assets and recorded data in Excel spreadsheets or maintenance software programs, but this practice was time consuming, prone to human error and only provided historical data, not actionable data. With the advent of the Internet of Things (IoT), connected sensors, devices and analytical software programs, the practice of asset monitoring become proactive rather than reactive, allowing users to identify abnormalities in the monitored variables in real-time and make informed decisions about when to conduct maintenance activities before failure or how best to use equipment so that downtime is avoided and productivity and uptime are maximized. While the real-time capabilities of this type of asset monitoring provide a wealth of benefits, deploying such a monitoring solution can be complex and time consuming, sometimes requiring months before it is useful.

However, Banner Engineering’s SNAP ID technology significantly reduces the complexity of this type of IoT project by providing a no-code platform in which wired sensors are instantly recognized by compatible gateways. The new technology allows users to begin monitoring equipment in minutes thanks to automatic recognition of compatible sensors that simplify installation and setup. The touchscreen display on the solution’s Asset Monitoring Gateway with SNAP ID provides simple, local access to machine data or Banner’s Cloud Data Service platform can present the data in customizable online dashboards. Both methods provide maintenance and production personnel with instant access to data so they may evaluate overall operational performance.

Getting Started with Asset Monitoring with SNAP ID

There are three steps involved with this simplified asset monitoring solution:

- Install and power up the Asset Monitoring Gateway.

- Select, connect and address up to 20 compatible sensors.

- Install sensors on equipment and commission the system.

There is no complexity when it comes to using this monitoring solution. Up to 20 condition-monitoring sensors can be plugged into the gateway, which can be used to commission the sensors, create unique names for sensors and groups and set warning and alarm thresholds. This means that within minutes of installation, critical system information can be viewed locally via the onboard touchscreen display or sent to the cloud for remote monitoring, giving operators and maintenance technicians instant, actionable insight into machine status so problems can be addressed before failure, equipment usage can be optimized to achieve higher levels of throughput and utility bills can be minimized. Machine status can also be viewed at a glance via an on-board status indicator that features a green-, yellow- and red-light system.

The Benefits of Asset Monitoring

The ability to quickly deploy the asset monitoring system and begin using it provides significant operational and financial benefits for industrial users, such as:

- Proactive Decision Making: By continuously gathering and monitoring data on equipment performance, usage and health, operators and technicians can detect any abnormalities in operation, performance and energy usage so proactive, informed decisions can be made about necessary maintenance or operating activities in order to keep equipment up and running at its most optimal.

- Reduced Downtime: Real-time access to asset variables such as vibration, temperature, pressure and other specifications makes visible any potential issues with equipment before catastrophic failure occurs. Not only does this prevent unplanned downtime, but it provides maintenance teams with the opportunity to troubleshoot, order parts and schedule repairs during planned outages or production lulls, further minimizing downtime.

- Utility Cost Savings: Viewing equipment data in real time allows operators and maintenance technicians to monitor and analyze equipment operational times, the effectiveness of the process and any abnormalities in energy usage. This information may be used to determine if changes can be made that will help reduce electricity consumption and, with it, the facility’s utility bills.

- Improved Overall Equipment Effectiveness: Users can monitor trends surrounding asset availability and productivity in real time so they can make proactive decisions that will improve the effectiveness of production equipment, helping to optimize equipment usage in an effort to reduce utility bills, boost facility throughput and create production schedules based on equipment availability.

These and other benefits of real-time asset monitoring can be available within minutes thanks to the simplified process of deploying the Asset Monitoring Gateway with SNAP ID, allowing manufacturers to make informed and proactive decisions surrounding predictive maintenance, energy usage, equipment allocation and production schedules, maximizing plant efficiency. To learn more, please contact Sensors Incorporated, a JHFOSTER company.