Month: October 2023

3 Advantages and Disadvantages of Cobots

As more manufacturers embrace factory automation technologies, many are exploring the use of collaborative robots, or cobots, as they tend to be more budget friendly than traditional robots and are well suited to industrial applications such as material handling, assembly, inspection and packaging. However, before implementing a collaborative robot, it’s important to understand the differences […]

An Introduction to Linear Motors for Straight-Line Motion Applications

As the price for linear motors becomes more cost competitive, these devices are more often being considered for motion control projects that demand high speed, fast acceleration and very precise linear motion. While linear motors have been around for a while and can provide significant advantages when properly applied, many people don’t know exactly how […]

The Rise of Electric Actuators

Traditionally electric actuators were not the device of choice for heavy-duty machinery, industrial equipment and other systems that demanded motion profiles with high forces and extreme robustness. However, reduced costs for these electric devices combined with recent technological advances are making designers reconsider electric actuators for use in these and other applications, giving rise to […]

3 Things to Know When Sizing an Air Compressor

Properly sizing an air compressor can make you feel like Goldilocks – one air compressor may be too big (leading to increased operating costs due to wasted energy) and another may be too small (resulting in inadequate airflow to equipment and problems with production). So, how do you find the air compressor that is “just […]

5 Tips for Integrating Pick and Place Robots

Automating pick and place operations with robots that select objects from one area and precisely relocate them to another can provide significant benefits such as greater efficiency and performance, increased safety and improved quality control. However, successful integration of pick and place robots demands research, planning and preparation. This blog will discuss the necessary considerations […]

Automated Inspection Systems Reliably Catch Packaging Defects

In the highly competitive packaging industry, damaged or defective packages can be a major drain on a packager’s profits and can result in lost customers. While there are any number of potential packaging defects, today’s automated inspection systems can help identify and prevent these problems, helping to ensure an error-free and more profitable packaging operation. […]

Innovations in Machine Tending Robotics Overcome Challenges

While manufacturers have eagerly replaced many manual operations with robotic automation to boost efficiency and throughput, machine tending has remained a manual process because it is was considered too complex to automate. However, because manual machine tending is a time-consuming, inefficient, repetitive, boring and often injury-prone task, it is usually well suited for automation, so […]

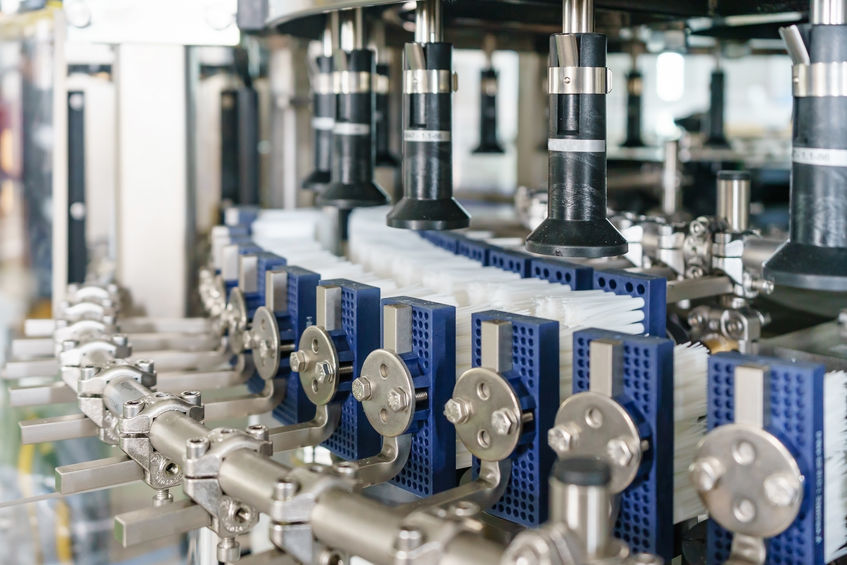

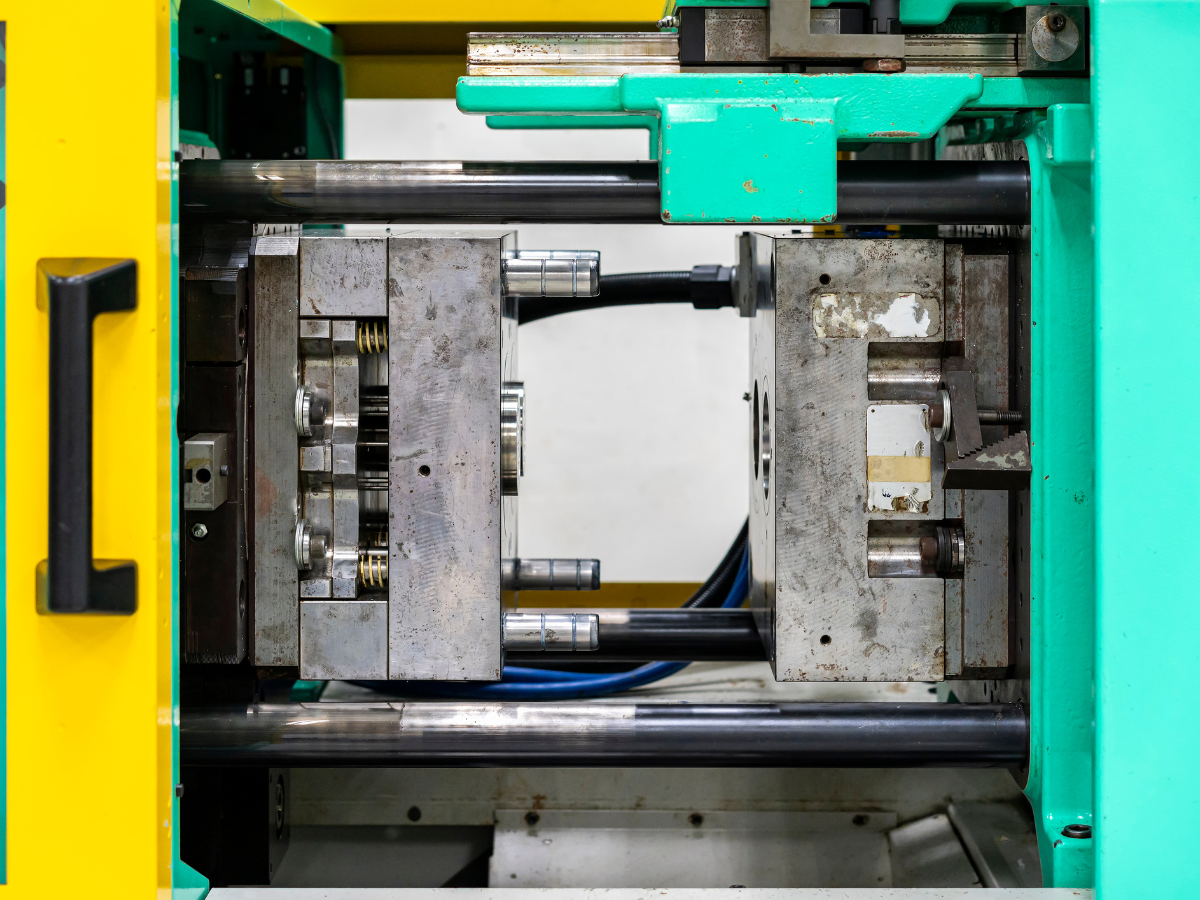

Automating Downstream Injection Molding Processes Provides Competitive Advantages

Automated work cells and robots are commonly used in injection molding processes for tasks such as part extraction, insert molding, over-molding, and in-mold labeling. However, there are many often overlooked downstream applications offering just as many benefits for injection molders who are looking to increase efficiency, quality and throughput while reducing costs. Automation in Injection […]

7 Questions to Ask When Choosing an Electric Actuator

Actuators are hidden within all types of machines and devices from industrial robots to automatic doors to cell phones. Because the function of an actuator is to enable movement by converting energy and signals into a mechanical force that pushes, pulls, lifts or otherwise moves parts of equipment and gadgets, actuators are an integral component […]