Month: October 2021

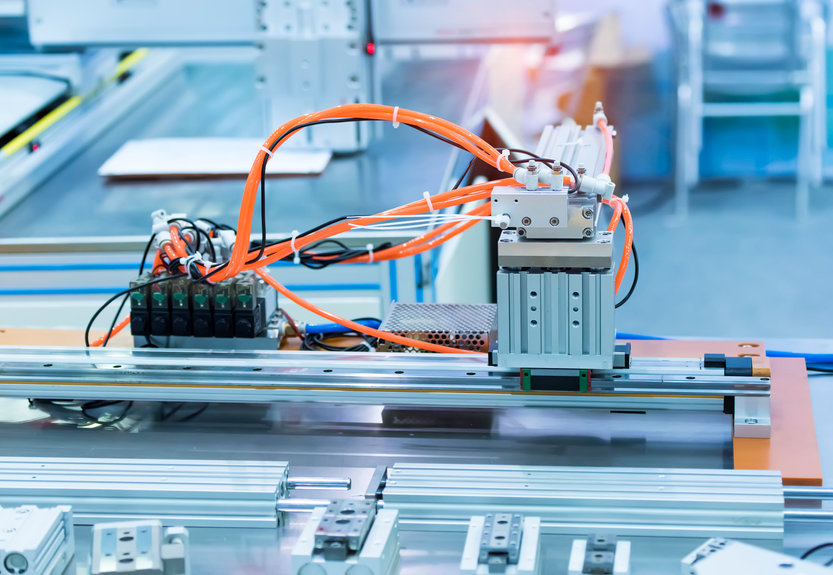

Simplify Industrial Applications with Collaborative Robots & EtherNet/IP Communication Protocol

Simplifying industrial applications can seem like an arduous task for yourself and your team. Maybe you have introduced collaborative robots to simplify repetitive tasks within your facility, but you are finding that your applications require multiple cobots running in tandem. Running many systems and technology at once to create your end-product can soon become complicated. […]

Types of Valves Based on Function, Ports and Operators

When a liquid, semi-solid material, steam, or air moves along piping to be used in an application, the flow of the materials needs to be regulated. Too much of the materials could be unwanted for the applications, cause damage to the system, or be dangerous for workers. Also, workers must have a way to close […]

Most Common Industrial Air Compressor Brands

Industrial air compressor manufacturing is a booming industry. There are global companies offering a range of different compressors with varying capacities. Ask different suppliers about the most common air compressors, and you may be given different lists. These companies may specialize in specific industrial compressors to cater to a niche industry, or they may offer […]

What Voids the Warranty of Industrial Air Compressors

Industrial compressors can be warriors in the workplace. From manufacturing to medical and petroleum to food packaging, compressors, pumps and vacuums perform a myriad of tasks, frequently with a minimum of maintenance. Well-maintained industrial compressors can last ten, fifteen, twenty years or more. This makes their purchase relatively infrequent. Even companies with multiple compressors may […]

Why Oil-Free Air is Critical in Medical and Pharmaceutical Manufacturing

Manufacturing processes rely on a wide range of equipment and mechanisms to create products for people around the world. The same holds true for medical and pharmaceutical manufacturers. These facilities use conveyor belts, drums, rotary devices, and compressed air to manufacture medical devices and medicines. However, unlike other companies, pharmaceutical and medical manufacturers must maintain […]

Top 10 Mistakes to Avoid When Designing Compressed Air Systems

Compressed air is an important component in the transfer of energy for use in industrial process. When designed properly, a compressed air system can reduce energy consumption dramatically, often resulting in energy saving of 10% or more. A poorly designed system, however, can lead to unnecessary downtime, loss of productivity, out-of-budget maintenance and repair costs, […]

What are the Types of Actuators

If there’s a piece of machinery operating within your industrial environment, then there’s a good chance that an actuator is working behind the scenes to help it do what it needs to be doing. But contrary to what you may think, there’s more than just one type of actuator – and the actuator that you […]

How Compressed Air Systems Evolved in the Last 20 Years

Compressed air systems are not a recent innovation. Society has utilized compressed air for centuries, from the foot-operated bellows used in metalworking in the 1500s to the vacuum pumps inventions for blast furnaces in 1650 and the first compressor plant built in 1888. The need for compressed air systems has evolved and changed to accommodate […]