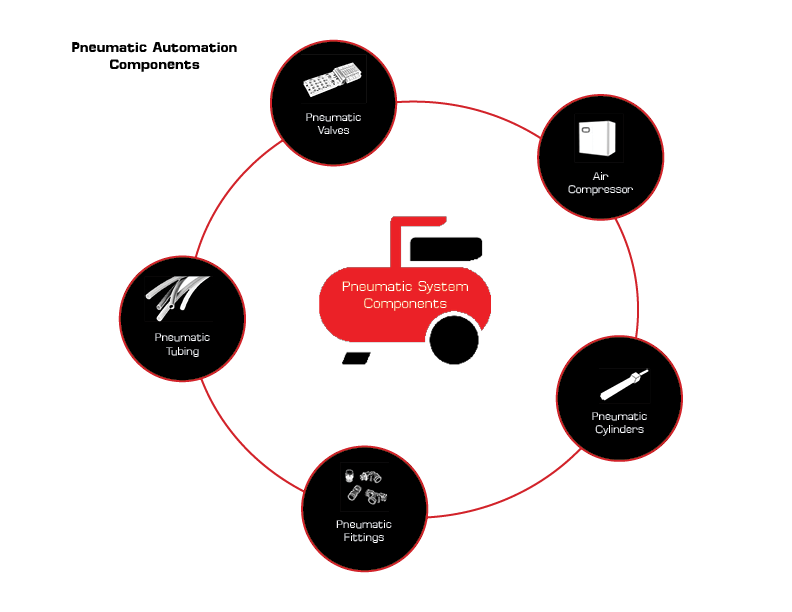

Types of Pneumatic System Components

Learn why each pneumatic system component plays an integral role in the performance of your system.

By definition, pneumatic movement means “the use of gas flowing under pressure to transmit power from one location to another”. Pneumatics is the use of pressurized gas that enables motion. That force or motion pushes, pulls, rotates, regulates or drives the system it is used for. Compressing atmospheric air creates a sustainable supply of compressed air. Therefore, pneumatic system components work so well in fixed installation, such as manufacturing facilities and factories.

Pneumatic systems use a variety of components to affect movement, as well as for control purposes. For efficient movement and control, the following pneumatic system components include:

As an air exhausting mechanism, this pneumatic equipment component sucks in outside air, compresses it and harnesses the air for use in your process.

A mechanical device used in a pneumatic system that produces force via compressed air is a cylinder. Once pneumatic cylinders are actuated, compressed air enters into the tube at one end of the piston and imparts force on the piston. This causes the piston to move.

Fittings provide control for your process. They connect valves and provide leak-free pneumatic movement.

Pneumatic tubing and hose convey pressurized air to actuators, valves, tools and other devices.

To ensure your pneumatic device runs efficiently, you need controlled air flow.

Advantages and Disadvantages of Pneumatic Control Components

Advantages:

- Simplicity of design and control – You design machines using standard cylinders and other components. In addition, operating the machine is simple with on-off controls.

- Durable and reliable – Pneumatic components are extremely durable and cannot be damaged easily. Also, pneumatic systems generally live long operating lives and require little maintenance. Since gas is compressible, equipment usually does not experience shock damage. This is because gas absorbs excessive force, whereas fluid in hydraulics directly transfers force. Compressed gas can be stored, so machines still run for a while if electrical power is lost.

- Safety – Pneumatic systems are safe because they can work in inflammable environments without causing fire or explosion. Overloading pneumatic components results in sliding or cessation of operation instead of burning or overheating like electromotive components.

- Highly effective – Many factories have equipped their production lines with compressed air supplies and movable compressors. The unlimited supply of air in our atmosphere makes producing compressed air easy. Moreover, distance does not restrict compressed air because it can easily be transported through pipes. After use, compressed air can be released directly into the atmosphere without the need of processing.

- High adaptability to harsh environments – High temperature, dust, corrosion, etc. does not affect compressed air compared to the elements of other systems.

- Easy selection of speed and pressure – The speeds of rectilinear and oscillating movement of pneumatic systems are easy to adjust and subject to few limitations. Pressure regulators adjust the volume of air easily.

- Economical – As pneumatic components are not expensive, the costs of pneumatic systems are quite low. Moreover, as pneumatic systems are very durable, the cost of repair is significantly lower than that of other systems.

Disadvantages:

- Relatively low accuracy – Compressed air powers the force of pneumatic systems. Consequently, their operation is subject to the volume of the compressed air. As the volume of air may change when compressed or heated, the supply of air to the system may not be accurate, causing a decrease in the overall accuracy of the system.

- Low loading – As the cylinders of pneumatic components are not very large, a pneumatic system cannot drive loads that are too heavy.

- Processing required before use – Compressed air must be processed before use to ensure the absence of water vapor or dust. Otherwise, the moving parts of the pneumatic components may wear out quickly due to friction.

Choosing the right components can be challenging since some pneumatic systems are more complex than others. We help you choose the best solution for your application and make sure you’re running at peak performance. From system evaluation to engineering solutions, installing projects and integrating systems, to providing service and distributing parts and equipment, we manage the entire process from start to finish for you.

For details on our complete line of pneumatic system components, or for information on the importance of pneumatic equipment in today’s automated facilities, contact one of our automation experts.