End-of-Line Shipping Automation: Boost Productivity and Reduce Costs

Manufacturers are under tremendous pressure to increase the efficiency of their shipping operations without compromising safety or consistency. Automating end-of-line shipping functions with robotic solutions, such as pick-and-place and palletizing robots that handle boring and hazardous repetitive tasks, allows your team to focus on more complex, value-added work, while also maximizing productivity, quality, and safety.

From designing and integrating the system to providing continuous support, JHFOSTER has the expertise to set you up with an end-of-line automation solution tailored to meet your requirements, so you can start shipping with greater efficiency and get back to focusing on your core business.

What is End-of-Line Shipping Automation?

Automated end-of-line shipping systems automate the final stages of the production process, from packaging and labeling to case packing and palletizing. Automating these essential functions prepares products for shipping with levels of precision and efficiency that cannot be matched with manual labor.

Engineered to Deliver Results: The Core Components

Dramatic improvements in speed and consistency of the tasks required to prepare products for shipping can be experienced with an automated solution. Key end-of-line shipping system components include:

Automatic Labeling and Label Printing: Automation of these functions ensures precision and reliability of tracking for security and compliance.

Machine Vision Systems: Used for barcode scanning and verification, quality control and inspection, machine vision systems effectively and consistently detect product flaws and defects before shipping.

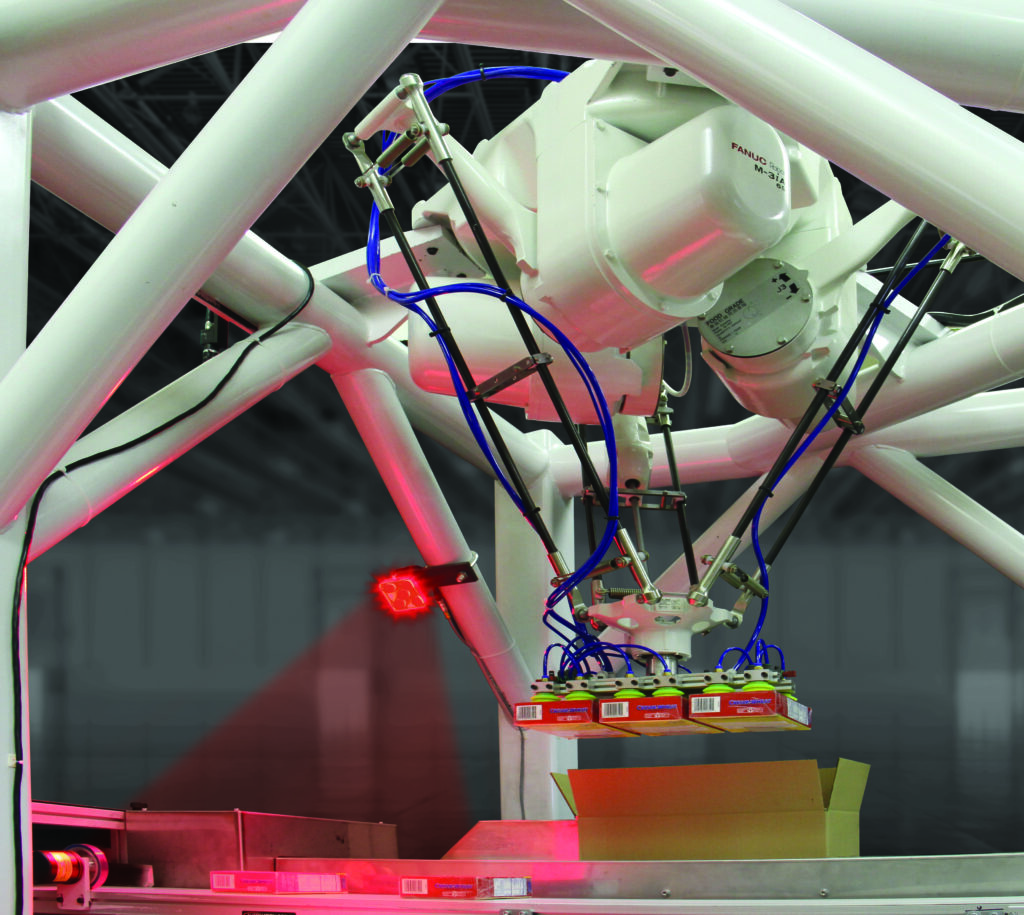

Case Packing and Palletizing Robots: Automating repetitive, heavy-duty tasks increases productivity and throughput and reduces orthopedic strain on employees.

Conveying Systems and Integrators: These automated systems seamlessly link all the components in the shipping operation to maintain flow, reduce bottlenecks, and maximize efficiency.

How Automation Reduces Shipping Costs and Maximizes Productivity

Automating end-of-line shipping tasks increases throughput and reduces costs by bringing higher levels of safety, speed, and consistency to the operation. Here’s how you’ll benefit:

Increased Throughput and Speed

Robots work continuously without fatigue or breaks, reducing cycle times.

Eliminate Errors and Reduce Waste

Precise and accurate robotic movements, barcode verification, and automated consistency and repeatability reduce product defects and packing and shipping errors, which improve quality and reduce costs associated with damaged products and scrap rates.

Lower Labor Costs and Injury Mitigation

By using automated systems for shipping functions, you can relocate staff from repetitive, strenuous, and injury-inducing tasks to higher-value roles. This lowers labor costs and reduces workers’ compensation, medical, and insurance costs.

Optimized Packaging

Consistent, uniform stacking and palletizing maximize load stability and reduce transportation/storage space ahead of shipping.

Common Automated End-of-Line Shipping Applications

Because of the many benefits, automated end-of-line shipping systems are used across a range of industries, including:

- Food and Beverage: Automation consistently manages high-volume packaging and adheres to sanitary/purity standards.

- Consumer Goods and Electronics: The use of robotics and automated systems enables high-speed, precision assembly, gentle handling of delicate components, and accurate labeling, while meeting high-purity requirements.

- Logistics and Warehousing: Automation is unmatched when it comes to managing high-payload palletizing, multi-SKU handling, and efficient continuous material transfer required in these industries.

- Pharmaceuticals: End-of-line automated solutions permit precise, contamination-free packaging and meet necessary high-purity requirements.

JHFOSTER: Your Partner in End-of-Line Shipping Solutions

Implementing automated end-of-line shipping systems starts with the expert guidance of JHFOSTER, your automation partner. We have the know-how to maximize the efficiency of your shipping operation from start to finish.

JHFOSTER engineers:

Evaluate: We’ll assess your current line, volume, and payload requirements to understand your operation and your challenges.

Design: Following the evaluation, our engineers will tailor a solution that includes the right technology, such as palletizing robots or pick-and-place collaborative robots (cobots) equipped with appropriate end-of-arm tooling, to optimize your workflow.

Install and Integrate: We’ll also manage the physical installation and technical integration, ensuring your new automation communicates seamlessly with your existing systems.

Support: We provide employee training as well as long-term maintenance agreements to ensure reliable performance for years to come.

JHFOSTER is ready to design and integrate an automated end-of-line shipping solution that prepares your product for shipping and gets it out the door with high levels of safety, consistency, and efficiency. Contact us for a quote today so you can get products to market faster.