Are Servo Motors Suitable for Your Application?

Servo motors provide efficient and precise motion control to many industrial applications. Several types of servo motors are available to meet the needs of even the most demanding applications. Here, we will explore the types of servo motors, their advantages, their disadvantages, and some of the applications for which they are suited.

What is a servo motor?

A servo motor is either a rotational or translational electric motor that applies torque or force to a mechanical system in response to electromotive forces in its stator from a servo drive. A control device such as a PLC sends a signal to the servo drive commanding it to move the servo motor to a specific position. The servo drive monitors the position of the servo motor using a feedback device and sends power to the windings of its stator to either rotate its rotor or slide its carriage to that position and hold it there.

| Servo motor disadvantages | Servo motor advantages |

| Due to their necessary complexity, servo motors and their control systems typically have a higher price tag than the equivalent stepper motors. They are also bulkier and much more expensive than their fluid powered counterparts | Servo motors offer far greater efficiency and accuracy of motion than pneumatic/hydraulic motors and actuators. Servo motors also provide competitive torque or speed and excellent power variability. Very rapid and precise changes in angular/linear position, velocity, and acceleration are possible because servo motors have less friction and employ a closed-loop control system; using feedback to control the motion. Servo motors are also durable and sanitary; able to perform in harsh or sensitive environments, while under heavy loads. |

Servo motor types

To meet the needs of a myriad of applications, servo motors are available in a variety of types, including standard, continuous rotation, and linear.

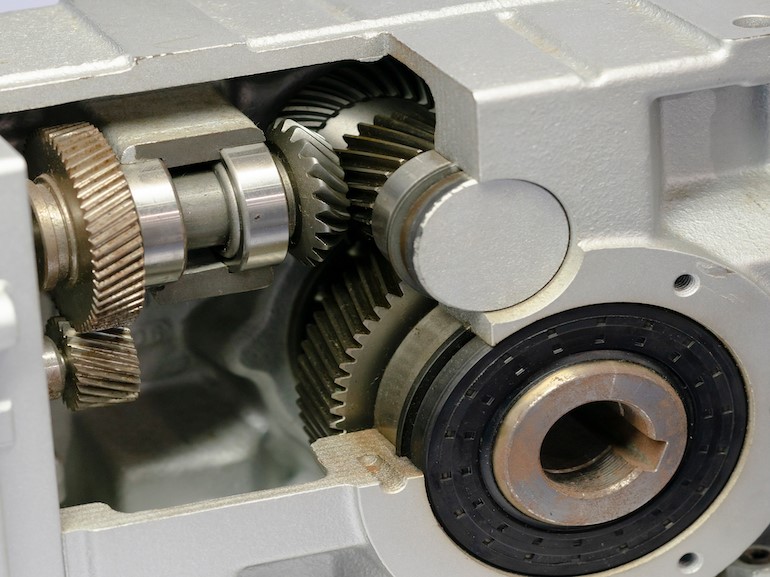

- Standard servo motors typically have an integral gearbox and an incremental encoder. The most common is the positional rotation servo, which can only rotate within 180 degrees between stops in the gear mechanism to protect the output shaft from over-rotation.

- Continuous rotation servo motors have no limit on their range of motion and can rotate continuously in either direction. They typically have absolute encoders to keep track of how many rotations they have made.

- Linear servo motors provide linear motion along an axis like a piston or a solenoid. In this case, the stator is made up of individual segments that are lined up end-to-end usually in the form track, and a carriage is forced to move along its length as the coils energize in sequence. The feedback device is also linear.

Servo motor applications

Servo motors can be found in a wide variety of applications. Some of the more common applications include:

- Conveyors, packaging equipment, material handling equipment, labeling machinery, and bottling lines.

- Robots almost exclusively use servo motors for their joints.

- Industrial textile equipment such as looms, knitting machines, and spinning machines.

- CNC machinery for 3D printing, machining, cutting, welding, and forming of various materials.

- HVAC, window, and door automation as well as solar panel aiming.

- Medical equipment such as centrifuges, scanners, X-ray tables, cameras, and surgical robots.

- Etc.

Although pneumatics and hydraulics will continue to dominate certain applications due to their higher power density and lower cost, servo motors’ competitive power and durability and their superior efficiency and accuracy will continue to reveal new opportunities with long-term benefits for adopting them.

For help selecting the best type of motor or actuator for your application, whether fluid powered or electrically powered, please contact a JHFOSTER representative.