5 Common Automation Pitfalls and How to Avoid Them

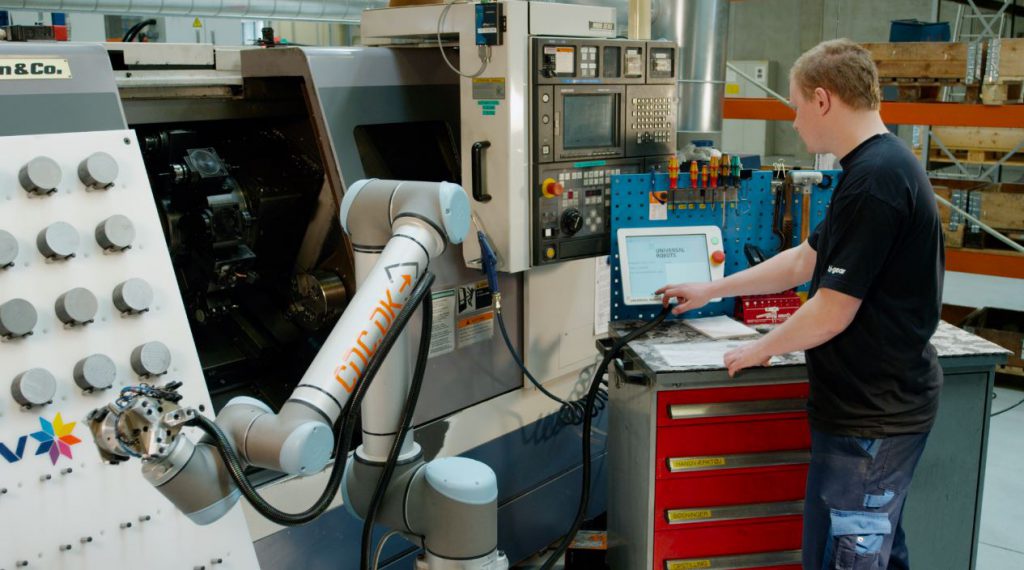

Industrial facilities worldwide are racing to automate processes and operations because automation provides significant bottom-line benefits when properly planned and integrated. But in the rush to implement automated equipment, businesses often overlook some of the most important details.

Unfortunately, making mistakes when applying automation inevitably leads to issues that will likely reduce the success of the project. Although the automation requirements — and challenges — of each facility vary, there are some common complications that can be avoided when armed with foresight. Here, we discuss five common automation pitfalls and how to avoid them so your automation project is a success story.

The Advantages of Automation

Before diving into the common challenges of automation, here’s a rundown of the benefits automation can bring to a facility:

| Increased efficiency and throughput | Improved quality and consistency | Improved safety |

| Automation of manufacturing tasks or processes improves efficiency and production rates. It improves the speed of production by boosting assembly time, reducing bottlenecks and allowing more output in the same amount of time compared to doing the same tasks manually. Automated machinery also minimizes cycle times, which helps increase throughput to meet production goals. | Product quality and consistency can be enhanced because human involvement and human error are removed from an automated process. Automation controls and monitors the process to provide uniformity and repeatability and maintain expected quality standards. | Automated machinery placed in hazardous areas improves the safety of the facility and protects personnel from working in dangerous environments. Replacing human operators with automation in operations such as pick and place that involve heavy lifting or repetitive motion tasks can help reduce workplace injuries. |

5 Automation Pitfalls to Avoid

While automation has measurable advantages, they are only achieved when automation is properly introduced, so it’s important to avoid common automation mistakes. Some of the frequently encountered pitfalls include buying the wrong equipment, lack of communication, not fully evaluating the process or project, not considering future needs and inefficient programming. Read on to learn how to avoid these missteps in order to get the most value from an automation project.

Buying the wrong equipment

You wouldn’t choose a sledgehammer when a tack hammer will do. The same theory applies to the selection of automated equipment, yet many mistakes are made when purchasing automated equipment. While the most advanced technologies with many capabilities and promises of high speeds and faster throughput may seem the most appealing, it may not be the most suitable solution for the application. It’s important to evaluate the requirements of the process to be automated and talk to a supplier about the most suitable technology so that the equipment you select has the proper end-of-arm tooling and the required speeds, motions and safety features for the job. Also important is ensuring that the selected equipment can connect to the existing equipment as it will need to communicate and work together to provide the functions and data necessary for process optimization.

Lack of communication

From the earliest planning stages, there must be communication with the equipment supplier and integrator to help define project goals and select suitable equipment. Equally important at this point is gathering input from the operators who work closely with the existing process and those who will be tending the automated process. Because the goal of automation is to improve operations and simplify workflows, insight from knowledgeable operators can help guide the project so the outcome achieves the desired goals and will, in fact, free workers to perform other, value-added tasks around the facility. As a bonus, involving operators will allow them to see that the aim of the project is not to eliminate their jobs, but rather to eliminate hazardous or boring manual tasks.

Maintenance teams should also be included in early discussions since they are the most knowledgeable about the line’s weaknesses, power requirements and space constraints and will likely be responsible for upkeep of the new automated equipment. This will help ensure that the project delivers a solution that solves existing problems rather than creating new ones. Taking the time to discuss the upcoming move to automation with those on whom it will have the greatest impact will help ensure employee buy-in, which is key to a successful project.

Not fully evaluating the project or process

It’s not uncommon for manufacturers to want to select the most complex process in the facility for automation; however, in the earliest stages of automating a facility, experts recommend starting with a simple process rather than a complex one because complex processes will require more automation, more equipment and more integration, which can be challenging for automation newbies.

Another misstep is choosing an existing process that is not yet optimized. Understandably, industrial facilities want to use automation to solve issues with bottlenecks and other challenging situations, but applying automated machinery will not overcome the inefficiencies if the process itself is the problem. To achieve the most success, experts recommend evaluating the process to identify inefficiencies, bottlenecks and concerns that affect throughput, working out the kinks and defining the goals of the process improvement before applying automation to avoid creating a situation in which you now have a poorly optimized process with automated equipment that doesn’t perform as expected.

Not considering future needs

Business tends to evolve quickly these days as industry must adapt to changes in customer needs, market trends and fluctuating economies, so it’s essential to consider whether the process to be automated will need future adaptations to accommodate different products, greater capacities or other process adjustments. For this reason, selecting automated equipment with the flexibility to be moved to another line or adapted via different end-of-arm tooling or programming might be a good idea if changes are anticipated in the future.

Inefficient programming

Two of the more common issues when introducing automated equipment involve inappropriate programming and not ensuring that I/O signals are properly aligned. Automated equipment may come programmed for certain speeds or motions, but these may not be the most suitable for the application. Taking the time to adjust the programming so that its speed and motions meet the needs of the application will provide the greatest efficiency.

Also crucial to automation success is ensuring that “handshake signals” and I/O handling are done correctly. When multiple machines need to coordinate within a single process, improper use of I/O and handshake signals can lead to damaged machines or equipment, line outages and failures. Also, to avoid injuries, ensure that safety features can not be bypassed by operators or maintenance techs and a risk assessment is performed.

While visions of efficient production lines with workers and automated equipment working in tandem to reduce bottlenecks and increase capacity are exciting, don’t rush the project. Careful consideration and planning are necessary to ensure that the project will be successful. Avoiding the above-mentioned pitfalls by ensuring that the equipment and process are properly aligned, including all parties in the discussion, planning for the future and programming automated equipment appropriately will go a long way toward the success of an automation project.

For more information on automating processes and operations please contact JHFOSTER.