Linear Motion Technology

Unloading from a conveyor belt, picking and placing packages in a carton and dispensing adhesive on a tray of components are all good applications of linear motion technology. Three axes of motion can reach any part of a rectangular or cubic volume, enabling processes from machine loading and unloading to cake decoration and drug discovery work.

Linear motion technology takes several forms, with performance and pricing varying widely. Selecting the right solution for any given application takes an understanding of what’s available and how to define requirements. Here’s some guidance.

Where to Use Linear Motion

Anywhere a process requires a repeated translational movement – from point A to point B rather than rotary – there’s an opportunity to save time and money with linear motion technology. For example:

- A gantry system that lifts a part from a conveyor and moves it to a packaging system (2 axes, maybe 3)

- Moving a dispensing nozzle over a line or tray of open containers (example: pipetting in a laboratory)

- Picking parts from a tray and inserting them into larger assemblies (gears into pumps, for example)

- A packing system using a single axis of motion to close a carton

- Picking a part from a conveyor and loading it into a fixture for an assembly or joining operation (2 or 3 axes)

Linear Motion Technology Options

The main components of a linear motion system are the guides and the drive mechanism. Other points to consider are the frame or structure, the motor or motors, and the sealing and lubrication.

The guides are the rails that carry the platform or carriage being moved. The options are:

- Slides – use low-friction polymer bearings that slide along a profile

- Wheels (or castors) – run on top or along the sides of a rail

- Ball bearings – incorporated into the platform where they roll along the profile in a recirculating arrangement

Drive options are:

- Belt – good for high speed movement and long travel

- Planetary screw – for low to medium payloads and speed, positioning repeatability to 5 µm

- Ballscrews – excellent efficiency, high thrust capacity and accurate to 5 µm or better

- Linear motors – high speed and high accuracy but limited payloads, expensive

Linear Motion Advances

Machine builders are always looking to increase speed and reduce cycle times while making equipment smaller. To meet this need, linear motion systems are becoming more compact and more powerful. Already more accurate and controllable than pneumatic rods, linear motion technology is becoming ever more precise and repeatable.

Another trend is straightforward connectivity. Manufacturers are simplifying what it takes to link components and have them work together.

Increasingly, industrial machinery users want data from their equipment. In response, linear actuators are gaining IIoT-style sensor technology that can communicate a range of operating parameters for process analysis and optimization.

Component Selection

The range of linear motion technologies and number of suppliers makes it challenging to design a system. Assessing factors like inertia, acceleration, payload and motor size is difficult and time-consuming. This leads some engineers to over-size, achieving performance goals while paying more than needed for overly bulky components.

Recognizing that design engineers need help selecting linear motion system components, Bosch Rexroth recently launched their LinSelect tool. A significant advance in system design, this generates component recommendations in response to performance and other criteria that the designer enters.

This saves significant design time and effort. Perhaps of greater importance though, it ensures components are matched to provide the overall performance and reliability needed.

Benefits of Using Modern Linear Motion Products

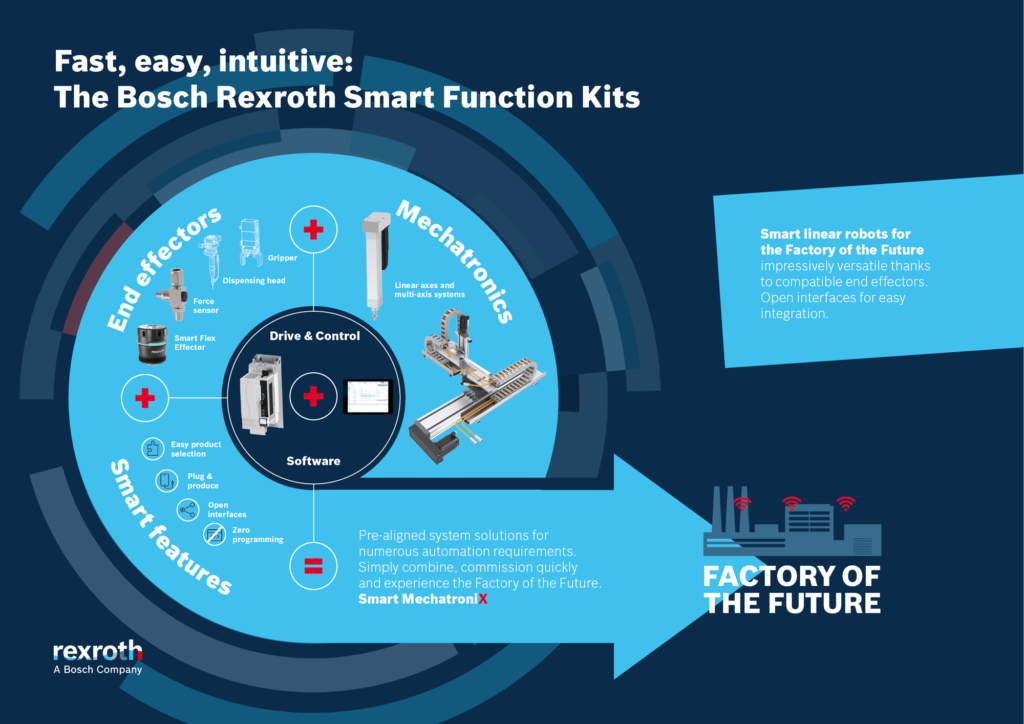

Manufacturers of linear motion products are striving to make design and assembly easier and faster. To this end, leaders like Bosch Rexroth incorporate features and elements that improve performance while making the designer’s task less difficult.

Benefits of the latest generation of linear motion products include:

- Plug & Play Application – components are designed in such a way that they connect and work together with the minimum of complexity (Bosch Rexroth provides an excellent example.)

- Flexibility – modern systems can deliver whatever payload, distance and speed are required, and can be reconfigured when needed

- Ease of Maintenance – with the inclusion of polymer bearings, sliding rail systems need no lubrication. Other systems have self-contained lubrication, and in all cases seals are better than ever

- New Applications – higher speeds and accuracy, coupled with easier integration, means linear motion technology can solve more problems throughout manufacturing, warehousing, and in other fields

JHFOSTER Can Help With All Your Linear Motion Needs

Linear motion devices boost productivity in many ways. Selecting the right systems and components can be a challenge, but JHFOSTER can help. Contact us to discuss your application, and take a look at the Rexroth LinSelect tool if you feel ready.