Electrical Safety Equipment for Industrial Manufacturing

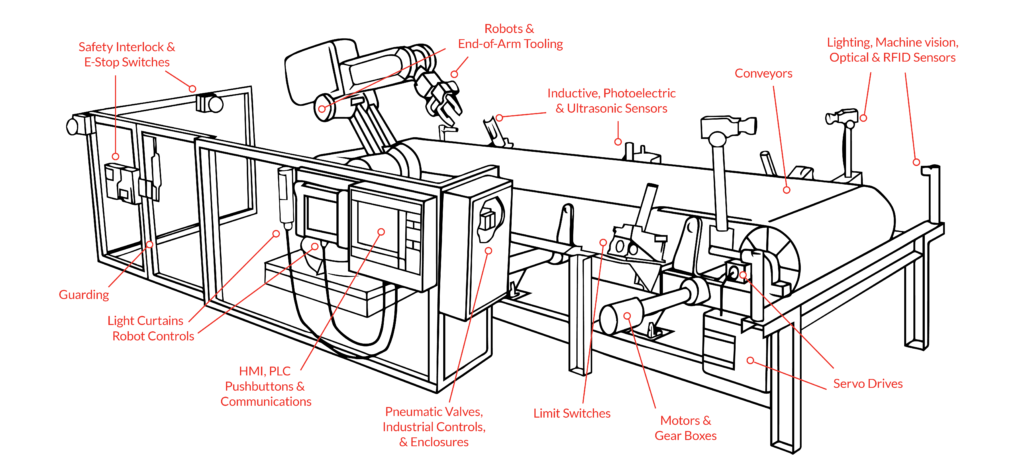

JHFOSTER distributes pneumatic and electrical safety equipment for industrial manufacturing applications. This includes manufacturing safety sensors and signaling products that improve detection, protection, and safety.

Our safety components are available for sale individually, as assembly kits, or as additional components to electronic control panels. Fill out our online form to request more information.

Importance of Machine Safety Standards

Industrial machinery poses many safety hazards when not handled correctly. When machine operators aren’t properly trained, they are at risk of injuries like skin abrasions, burns, cuts, and punctures.

Scheduling regular risk assessments can ensure all machines meet safety standards to prevent potential injuries from hazards.

Precautions that Manufacturers Take to Avoid Risks

Workers in the manufacturing industry deal with heavy lifting, rigging, raw material assembling, metal cutting, welding, and other high-risk activities on a regular basis. Safety precautions are necessary for manufacturers to minimize occupational accidents and prevent operational setbacks:

- Conduct a thorough risk assessment to identify all possible hazards.

- Prioritize housekeeping to avoid fires, slip-trip-fall incidents, and other accidents.

- Require workers to wear personal protective equipment while in the manufacturing area.

- Make sure all guarding mechanisms in the workstations are correctly installed.

- Schedule regular training on safety protocols and equipment handling.

Recommended Products and Solutions

Find the right safety equipment and solutions for any type of environment in the manufacturing industry. View additional products and solutions that can lead to a safer work environment.

Literature Library

Looking for additional information? Check out JHFOSTER’s Automation Library.

TECHNOLOGY

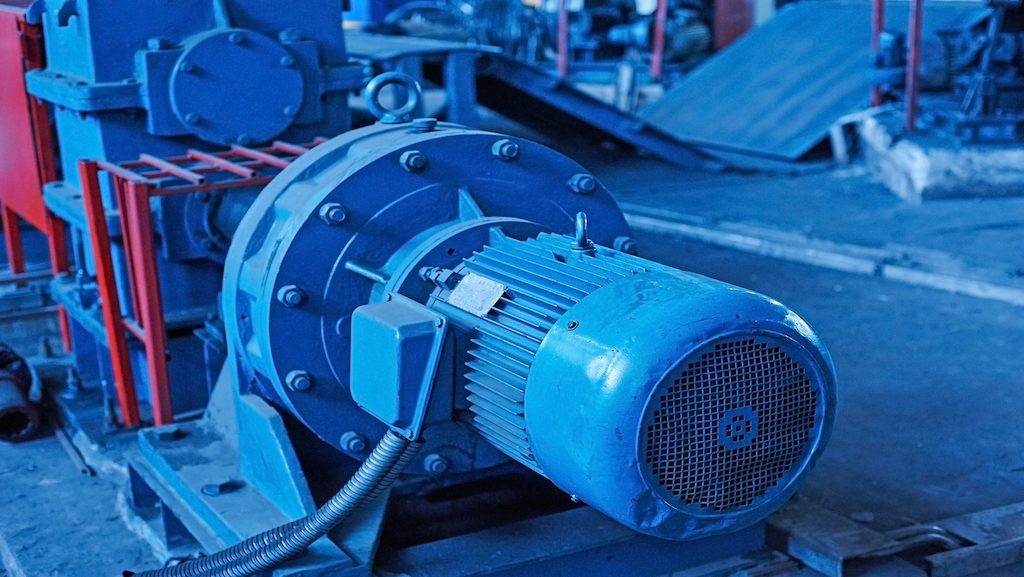

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

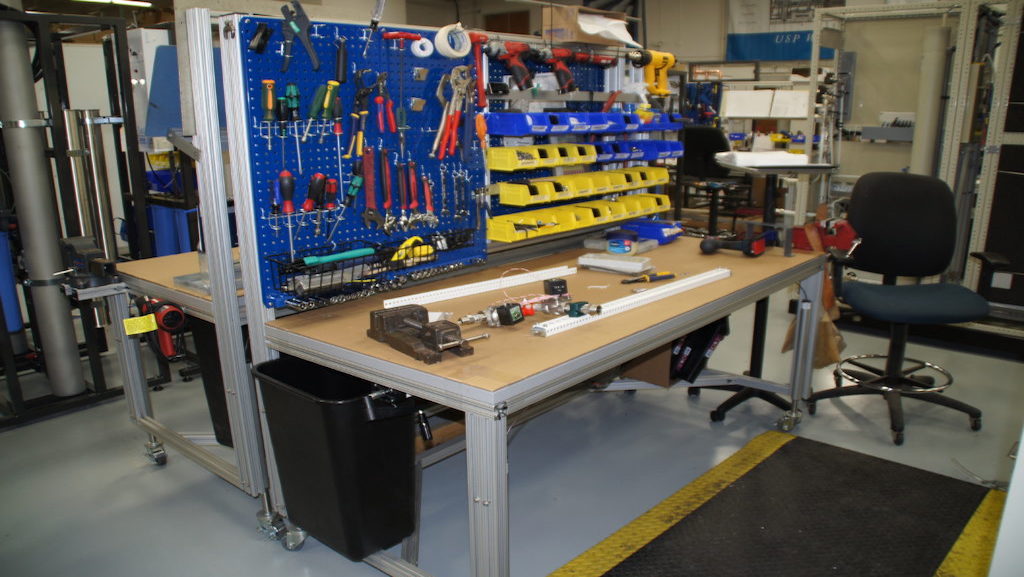

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

Frequently Asked Questions

Industrial machinery isn’t necessarily dangerous. But, it may cause various injuries when not handled properly. The following workplace injuries may result from not following equipment handling and maintenance safety protocols:

- Abrasions from rough surfaces

- Burns from steam or hot surfaces

- Cuts and punctures from sharp edges

- Concussions from moving or ejected objects

- Limb injuries due to moving parts like belts and rollers

Workers in the manufacturing industry are exposed to high-risk activities like welding, metal cutting, and raw material handling. They are also exposed to occupational hazards, such as compressed gasses, harmful radiations, and magnetic fields.

This is why manufacturers should invest in safety equipment and implement machine safety protocols.