Servo Reducers & Couplings

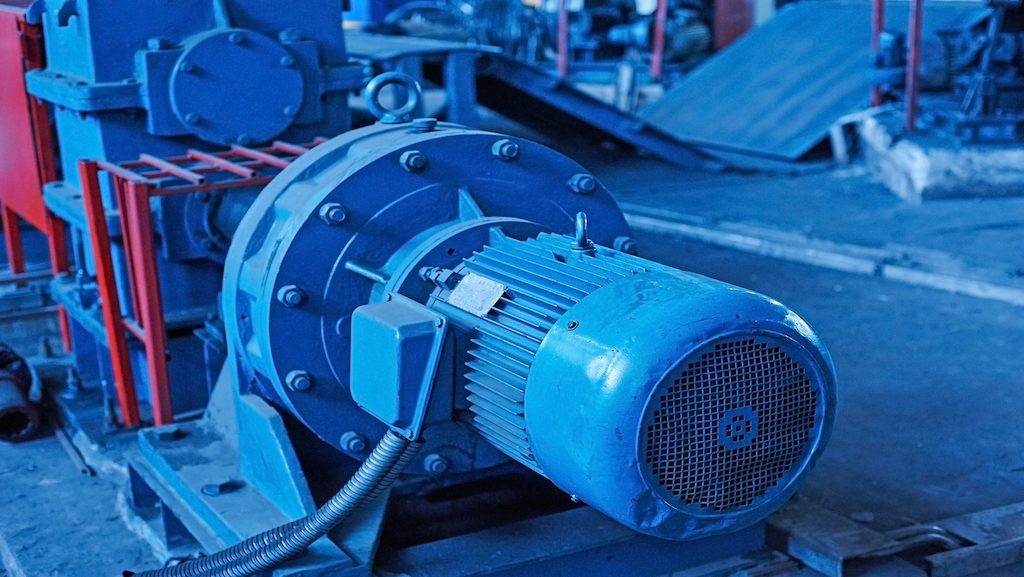

Speed reducers are gearboxes used to increase torque and lower rotational speed simultaneously. Servo reducers are just a special type of speed reducer meant to be used with servo motors. Servo reducers (or gearboxes) are employed in high-torque and low-speed applications. They can also be used to match the load’s inertia to the motor’s, so the load does not drive the motion. Although an inertia ratio of 1:1 would be ideal, it is not always possible due to mechanical or cost constraints. A good rule of thumb is to aim for an inertia ratio of not more than 10:1.

Servo Reducer Types

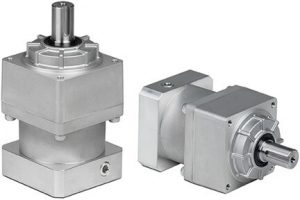

Servo reducers can be classified by the alignment of the input and output shafts into inline, parallel (also known as offset), or right-angle (shafts are placed 90 ° from one another). Inline servo reducers are the most common type. Parallel and right-angle reducers are used when a certain machine configuration cannot be changed, and space is limited. Right-angle gearboxes are less efficient and less compact than inline configurations; so, when possible, most applications will ideally use an inline gearbox.

Servo reducers can also be further classified by the type of gears used in their constructions: helical, hypoid, worm, planetary, etc. Helical and planetary gears are used for inline and parallel configurations. They both offer highly efficient, high-torque, low-noise, and low-vibration movements. Hypoid, worm, and planetary gears are used for right-angle configurations. All of these are known for their high-torque, low vibration, and low-noise capabilities. Worm gears also offer a built-in brake mechanism because they cannot run in reverse (although this comes at the expense of energy efficiency). Planetary right-angle gearboxes have the same features as their inline counterparts. Overall, the type of servo reducer selected for an application will depend mostly upon the reduction ratio needed, its smoothness and its cost.

Recommended Products and Solutions

Nidec-Shimpo

Nidec-Shimpo offers a variety of servo reducers for practically any application. The types of servo reducers they carry are:

- Inline planetary gearboxes

- Right-angle planetary gearboxes

- Right-angle hypoid gearboxes

- Right-angle worm gearboxes

- Cycloidal gearboxes

- Strain wave (harmonic) gear units

- Rotary Index Tables

STOBER

STOBER also offers a variety of servo reducers including inline, offset, and right-angle units.

Couplings

A coupling is a mechanical device used to connect two shafts together. Its primary purpose is to transmit power from the driving shaft to the driven one. However, it can also be used to absorb the forces generated by slight misalignments and mounting errors by using flexible materials, to reduce long-term wear and prevent premature component failure. Another purpose could absorb the vibrations created by the motor and any shocks from emergency stops or power losses. Additional applications include introducing torque overload disconnection mechanisms, or static eliminating special couplings for hazardous areas.

R+W

R+W offers a variety of backlash free precision couplings for high-performance applications. Precision couplings offer a more compact and torque denser design than traditional couplings. The specific products available from this manufacturer are:

- Metal Bellows Couplings – For 5 – 10,000 Nm applications

- Miniature Bellows Couplings – For 0.05 – 10 Nm applications

- Elastomer Couplings – For 0.5 – 25,000 Nm applications with vibration dampening

- Safety Couplings – For 0.1 – 2,800 Nm applications with torque overload protection and low inertia

- Line Shafts – For 10 – 25,000 Nm applications and larger distances

- Servo Disc Pack Couplings – For 25 – 100 Nm applications

Zero-Max

Zero-Max offers a variety of flexible shaft couplings that prevent premature component failure, dampen vibration, reduce noise, and protect from overloads. Zero-Max’s flexible couplings perform better than rigid coupling in high-performance applications and require no lubrication for a practically maintenance-free solution. The specific products available from this manufacturer are:

- Composite Disc Couplings – Zero backlash, from 0.25 ” to 6.00 ” diameters and torques up to 94,000 lb-in

- ServoClass® Couplings – High torsional stiffness, superior misalignment capacity and reduced reaction loads. Up to 2,220 lb-in torques and available in 14 sizes.

- Control-Flex Shaft Couplings – Zero backlash and vibration resistant. Designed to be used with feedback devices like encoders.

- Schmidt Couplings – For especially large misalignments.

Contact Us Today for Free Consultation

Do you need advice to select the most appropriate servo gearbox or coupling for a specific application? We are eager to help your company come up with the best possible solution! Our technicians are available via phone or email. Contact us now for a free consultation!

Literature Library

Looking for additional information? Check out JHFOSTER’s Automation Library.

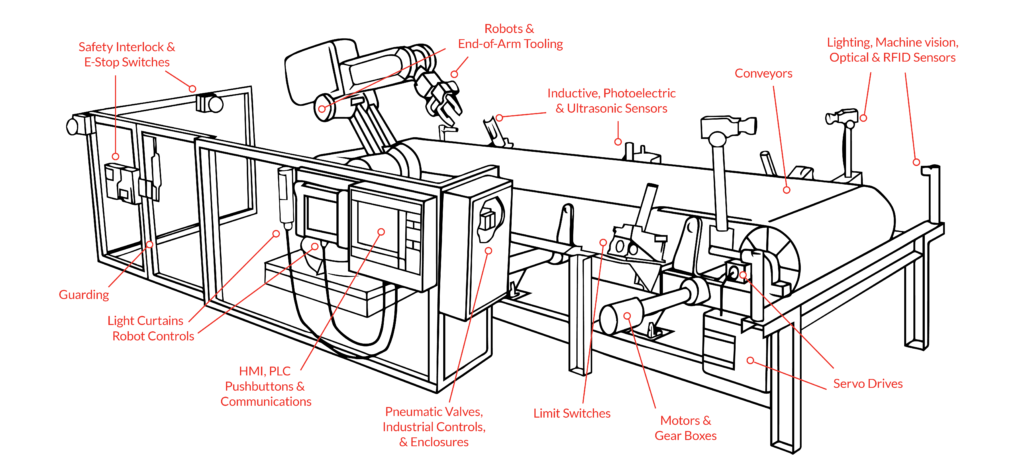

TECHNOLOGY

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam