Servo Motors

Best-In-Class Servo Motors for Industrial Use

Servo gear motors are electric motors that rotate or move a shaft in response to a signal from a control device.

They are commonly used in radio-controlled models and robotic applications.

The control device sends a signal to the motor’s control board to move to a specific position. The motor then rotates or moves to that position and stops. Servo motors are powered by various power sources, including batteries, solar panels, and mains electricity.

JHFOSTER servo motors offer high speeds and accelerations, as well as high precision in terms of positioning and rotational speed. They provide exceptional torsional stiffness and backlash to meet the demands of highly dynamic applications.

Our servo motors are available in various sizes and power levels to suit the specific needs of your application.

Get unmatched reliability that you won’t be able to find in any other servo motor distributor in Minnesota.

Servo Motor Applications

Servo motors are versatile and can be used in a wide variety of applications, including:

- Radio-controlled models

- Robots

- Automatic doors

- Security systems X

- Factory automation equipment

- Office equipment such as printers and scanners

- Medical equipment X

- Home theater systems X

Different Types of Servo Motors

There are a variety of servo motors available on the market. This includes:

- Standard servo motors: These servo motors have three phases and are the most common servo motors. They can rotate or move to a specific position in response to a signal from a control device.

- Continuous rotation servo motors: These servo motors do not have a limited range of motion and can rotate continuously in one direction. They are often used in robots and other applications where continuous movement is required.

- Linear servo motors: As their name suggests, they operate in a linear (rather than rotary) motion and are used in applications where linear movement is required, such as in printers and scanners.

Brushless servo motors: These servo motors are more efficient than standard models and have a longer lifespan. They are often used in industrial applications, such as factory automation, conveyor systems, packing machines, sorting systems, and material handling systems.

Your Source for Top-Notch Servo Gear Motors

Increase efficiency and reduce maintenance costs with high-precision servo motors designed to meet your production demands. Our certified technicians will guide you through the specification and design phases and answer your questions, so there are no surprises once installation begins.

Reach out to us now to receive your free quote. For questions regarding our products and suppliers, don’t hesitate to contact us at 855-688-0065.

Literature Library

Looking for additional information? Check out JHFOSTER’s Automation Library.

TECHNOLOGY

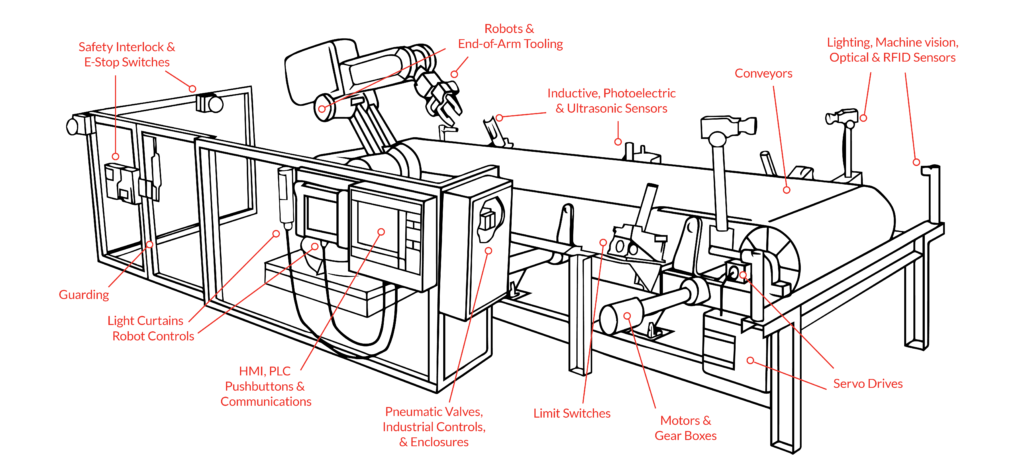

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

Frequently Asked Questions

Servo motors and stepper motors are electric motors used to move or rotate a shaft or arm in response to a signal from a control device.

However, servo motors have a limited range of motion and can rotate or move to a specific position, while stepper motors can only rotate continuously in one direction.

Servo motors can be either AC or DC. However, most servo motors used in the industrial market today are AC motors.

When choosing a servo motor, consider a number of factors, including the power source (AC or DC), voltage requirements, speed and torque requirements, size and weight of the motor, and the environment the motor will be used in (indoors or outdoors).