Why Should You Focus on Your ISO Specs?

Depending on what your industry’s goal is, it’s important to use ISO standards in your facility.

We know the world’s largest creator and publisher of international standards as ISO (International Standards Organization). The standard has nine separate parts relating to the quality (or purity) of compressed air. In 1991, ISO created the 8573 compressed air quality standard to help compressed air system component selection, design and measurement. ISO standards detail the amount of contamination allowed in each cubic meter of compressed air.

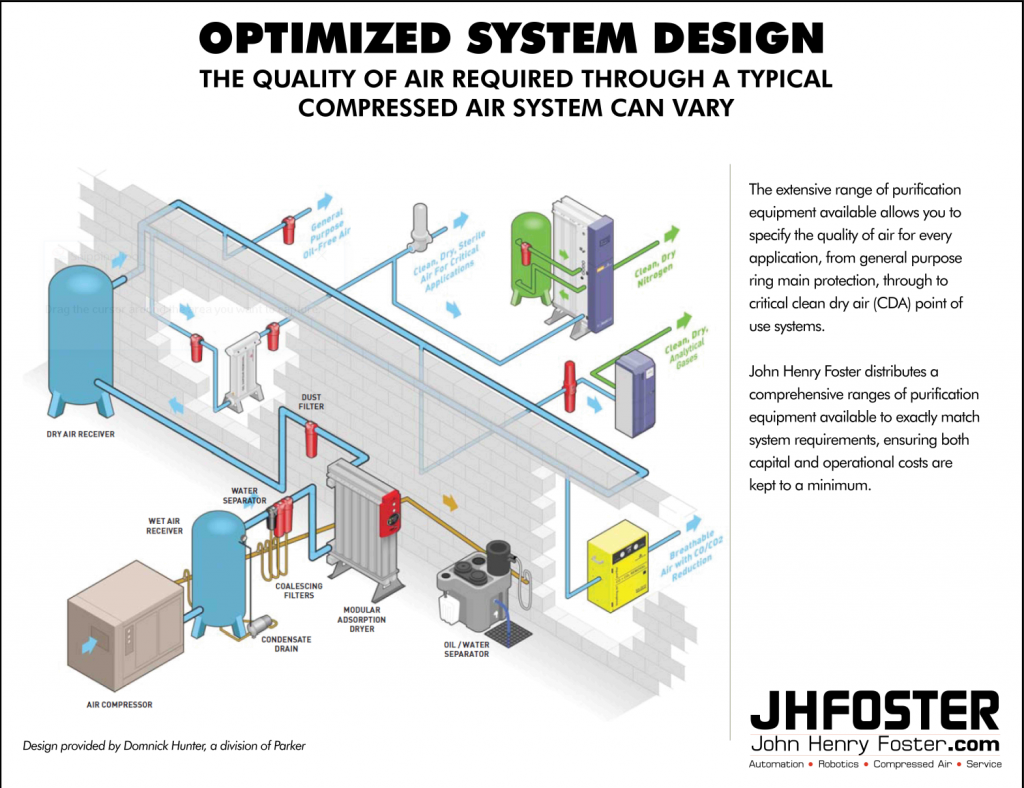

The quality of air required in a typical compressed air system varies.

ISO 8573 Air Quality standard raises end-user focus of how to measure and define the quality of compressed air. This standard describes the air quality levels and methods to find contaminants found in your air system. Similarly, the ISO 12500 test standards gives the means to separate and filter products through certifiable performance to manufacturers.

By installing specific options of ISO approved products, you meet compressed air standards. Further, ISO keeps refining its standards for the betterment of the compressed air industry. Are you using the systems that saves you the most money in your industry and that also meets ISO standards?

What is the Harm in Having “Too Clean” Air?

Being in the compressed air industry for nearly 80 years, we found that some businesses might not need the type of compressed air systems they currently use. For example, many businesses stay with the compressor they have always used. However, these units may give out cleaner air than what is actually needed. Utilizing the wrong compressor and parts creates more harm and:

- A Bigger Cost: The cleaner your air needs to be, the more pricey the equipment

- Keeping up with more features and parts: This will require more costs and maintenance

- More time needed: Changing filters, desiccant, etc. requires more time versus other systems.

What is the Harm in Having Not Enough Clean Air?

The medical industry requries high-quality compressed air. In addition, industries providing food products that are not only cost friendly to process but also safe to eat require quality compressed air. Therefore, it’s in your best interest to select the right compressed air equipment for food processors, medical industries, etc. The wrong equipment means:

- Product Quality Issues: Machines not up to standard risk products and users.

- Potential Safety Incidents: Contaminants meeting food via water and oil create safety concerns.

- Poor Quality Finishes: Contaminants mixing with applications effect product results. For example, if the oil from an air compressor drips on paint, the product would then not dry as fast or correctly.

[rara_divider color=”#CCCCCC” style=”solid” thickness=”1px” width=”100%” mar_top=”20px” mar_bot=”20px”]

[rara_call_to_action title=”Where Do You Start?” button_text=”Read More” button_url=”https://jhfoster.com/blog/five-areas-of-focus-when-installing-your-compressed-air-equipment/” target=”_self” button_align=”center”]Not sure where to start when installing your Compressed Air System? We can help. [/rara_call_to_action]

JHFOSTER provides innovative and state-of-the-art products. In addition, we expanded to include a range of industrial robots. Further, our team of experts support your productivity and efficiency needs with our versatile products and services. Please contact us today at 651.452.8452 or email us to learn more about our line of air compressors, vacuum equipment, engineering and design capabilities, or any of our product offerings. Also, you can read more about on our website.

[printfriendly]