The Differences Between Rotary and Linear Pneumatic Actuators

Pneumatic Actuators are Linear or Rotary

Linear Pneumatic Actuators

can move something in a straight line using a piston with compressed air applied to achieve linear motion. The output motion of Linear Pneumatic Actuators is in line with the piston rod and/or cylinder.

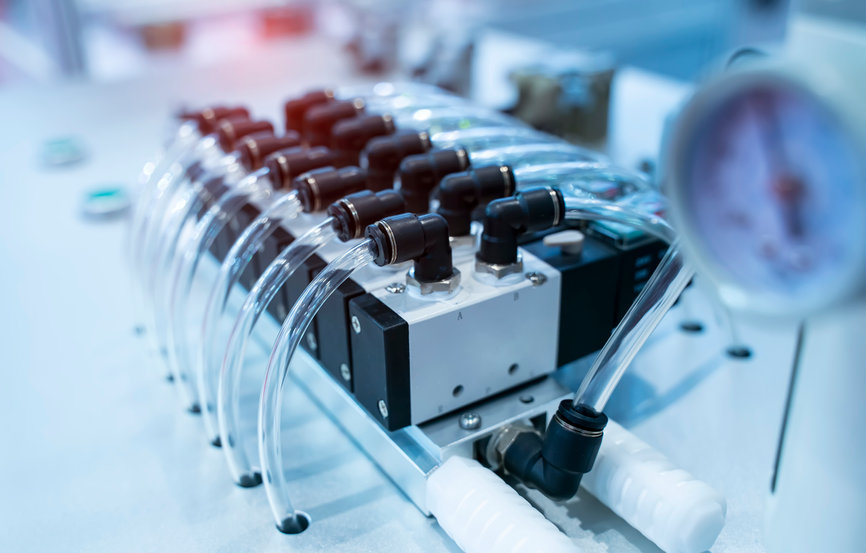

Rotary Pneumatic Actuators

can move something in a circular motion. Perpendicular to the shaft. Many contain pneumatic piston-operated rack & pinion assemblies, vanes, or other means to achieve rotary motion.

What does a Rotary Pneumatic Actuator do?

Rotary pneumatic actuators transform pneumatic energy into mechanical rotation. It can be oscillating or continuous motion when using a vane type or oscillating only when using a rack & pinion type.

What does a Linear Pneumatic Actuator do?

As mentioned earlier, linear pneumatic actuators move in a straight line. The two most common are rod and rodless type, both operating in a reciprocating motion using compressed air applied to a piston/cylinder assembly. The push-and-pull action will allow the device to slide, tip, lift and lower items with the push of a button.

How are Linear and Rotary Pneumatic Actuators powered?

Linear and Rotary Pneumatic Actuators generate operating energy through the efficient use of compressed air. The air builds up force or pressure which is applied against a piston, vane, or diaphragm. Mechanical motion is the result. Linear and Rotary Actuators can be pneumatic, hydraulic, or electric.

In what ways are Linear and Rotary Pneumatic Actuators different?

Other than the basic motion described above the primary difference between the two is unlike linear pneumatic actuators, some rotary pneumatic actuators are not restricted by the distance they can travel. Unlike Linear Pneumatic Actuators, some Rotary Pneumatic Actuators are not restricted by the distance they can travel.

How are Linear and Rotary Pneumatic Actuators typically used in Manufacturing Processes?

| Linear Pneumatic Actuators can be used for any straight-line movement including | Rotary Pneumatic Actuators are commonly used in industrial applications including |

| Opening and locking doors | Controlling valves |

| Closing dampers | Transferring parts |

| Braking machine motion | Conveying |

| Clamping | Clamping |

| Pressing | Positioning |

| Pushing-pulling | Pick & place |

| Lifting-lowering |

Why are Linear and Rotary Pneumatic Actuators used in so many industries?

They are durable, offer simplicity, and high force for their size. They can operate in hazardous environments. They are often preferred in applications where rapid opening or closing is required. Linear and Rotary Pneumatic Actuators are versatile in their applications and environments. They can usually operate at a wide range of temperatures. Their typical temperature range is: -40° F to +250° F.

What if I have questions about Linear and/or Rotary Pneumatic Actuators?

One of our technicians would be happy to discuss any questions you may have about Linear and/or Rotary Pneumatic Actuators. We have experienced and knowledgeable consultants at JHFOSTER. Contact one of our automation specialists to assist you in finding the right technology for the needs of your business.