Proof-of-Concept Testing Eases Robotic Automation Project Risks

Many industrial organizations are interested in improving efficiency, safety and productivity through the use of robotic automation but waffle on taking the first step. Understandably, the decision to invest in technology can be intimidating, especially when robots are new or unfamiliar to the facility and the project carries a significant capital investment.

Before making any major decisions, project managers and engineers undoubtedly want to know whether the project will successfully accomplish the task they wish to automate and if it will provide a worthwhile return on investment. Other questions might include how effectively the project will increase efficiency and productivity and/or how the existing labor force will interact with the new technology.

With so many unanswered questions, the decision to invest in and implement a robotic automation project can be intimidating. However, a proof-of-concept test is likely to provide answers to many of these questions and reduce the associated risks.

This blog will define proof-of-concept testing, explore the potential benefits and discuss what to look for in a proof-of-concept partner.

What is Proof-of-Concept Testing?

Proof of concept involves the design and testing of the specific aspects of a proposed robotic automation solution. The objectives of proof of concept testing usually involve evaluating the feasibility of implementing the project, demonstrating tangible benefits through a small-scale implementation of the project, identifying and preventing challenges that might pop up when implementing the project and developing a budget and project plan.

Proof-of-concept testing should:

| Confirm capabilities | Prove payload | Identify obstacles | Determine budget |

| This type of testing can prove the robot meets the needs and specifications of the application, and confirms the speed, throughput capacity and other factors, such as robot reach. | Proof of concept can determine that the robot can handle the specified payload weight and size. | Testing can point out any existing obstacles that may prevent the robot from completing the task, such as interference from surrounding structures or equipment. | Proof of concept can also be used to help create and develop a budget for the project and identify any extra expenses early in the planning stages. |

Benefits of Proof-of-Concept Testing

While videos and demonstrations of robots abound online and at automation expos, what you see in a showroom is not necessarily what you get once that same robot is placed in a customized facility and expected to perform a specific task. However, because a proof of concept allows project teams to observe the robot in action under the same circumstances and specifications in which it will be installed in a facility, it will help prove whether the anticipated solution will or will not work within the application. It will also provide information that can be used to make a business case for the investment and a way to build confidence that the solution will provide tangible benefits to the bottom line, reducing project risks.

Because proof of concept accounts for the specifications of a particular application, it can help address issues before installation. Ironing out any potential wrinkles prior to integration allows customized modifications to be made that may yield higher efficiencies and throughput. It will also help the integration itself go more smoothly as any obstacles or issues have already been noted and planned for, which encourages a rapid installation and implementation. In addition, the project team, engineers and operators will have a better understanding of the robot’s capabilities and limitations.

Examples of Proof-of-Concept Tests

While there are many different types of robots and even more applications, some common proof-of-concept tests include:

- Robotic cycle time testing

- Robotic payload testing

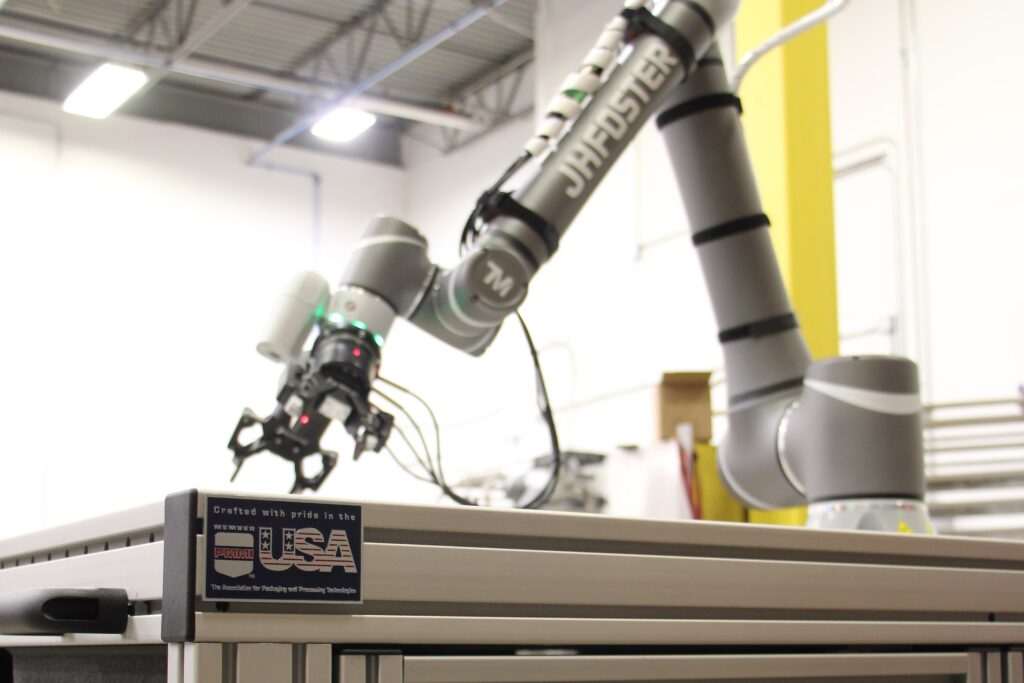

- Testing different grippers for a collaborative robot application

- Motion control tuning and coordination

- Testing of machine vision systems

What’s Involved in a Proof of Concept?

There are usually a few steps involved in a proof of concept. The first of which includes selecting and discussing the chosen application. Next, the software, automation hardware and robot are selected and configured for the identified process on a small scale. Testing will then occur to ensure that the solution meets the desired results. It may need to be refined and tested again. Key challenges should be identified and rectified to provide the most efficient solution. The results should be validated and documented.

How to Choose a Proof-of-Concept Partner

In addition to selecting a partner who can offer a variety of solutions, it’s also important to choose a proof-of-concept partner who understands the environment, industry and application specifications. Testing and training should be conducted by properly licensed electrical and mechanical engineers and those who encourage and understand applicable safety regulations.

For information on our proof-of-concept testing capabilities, please contact JHFOSTER.